Hmmmm…never really thought about industrial spying, but I guess it makes sense. Kind of sad really – I’d think you would want to be the innovator and not the copier.

Only if you’re a true Maker at heart. Building something that didn’t exist before makes you a Maker. Copying something someone else has created trying to beat them to market makes you an opportunist.

I generally avoid those wherever possible.

Personally, if I was working on a product I would be both. Innovate and put out my ideas, hoping to keep them hush-hush enough to be first to market.

But I would sure as hockey sticks keep tabs on any and all competitors to see if they are implementing any features I didn’t think of, and could easily add (or improve on) without too much of an adjustment to my timeline.

My day job is innovating but I keep up with what everyone else is doing and take inspiration from it all day long. Often the right product is one that takes a well-understood foundation and simply improves on it.

If you’re going to be an innovator, you also have to be very self-aware and realize when your innovations are too damn clever for your own good!

It’s faster & cheaper to imitate than it is to innovate.

Not always.

Trying to copy, duplicate or reverse engineer someone else’s design automatically imposes the constraints of that design onto what you’re trying to achieve.

Whereas starting from scratch, no holds barred, no constraints is easier because you’re writing your own play book. The additional work is offset by how quickly you can make decisions because you’re not already encumbered by some other set of rules.

up front maybe, but on the back end a lot of times you lose out. look how microsoft blew it in the mobile phone industry by waiting for apple to make the iphone before they jumped in. apple made it there first and did it right and it made them one of the biggest companies in the world. microsoft under ballmer was famous for half-baked copies of market leading tech. yeah its out there and it sells, but its not going to make the money that someone who is an industry definer would.

Completely true, and while the Muse will have a jump on things by a couple of months up front, once the GF delivers, new buyers will be comparing the two and finding that one costs more with fewer features, and the other costs less and gives more. Seems like a tough way to try to be competitive.

Microsoft actually had the most popular smartphone OS before Apple came along (it was apparently selling better than Palm, which I’m assuming was the second most popular at the time). It’s interesting how making something “better” than the competition sometimes gets mistaken with being first.

True, but oftentimes the resulting work is cheap in every sense of the word ![]()

Hey,

So some time ago I’ve written an email to FSlaser to clarify some PR blurb from their website and below is the email I got back. There is some repeated info from before, but thought I would post in case anyone needed some 1st hand confirmed stuff.

Thank you for contacting Full Spectrum Laser. Please see my responses below :

Do you ship to the UK and if yes for how much? What is the earliest time you can ship the machine?

- Shipping is roughly $550 to the UK. To get an accurate quote, I would just need to get your shipping address. We are currently shipping the machine so orders placed now will either ship at the end of this month or the beginning of next.

Do you have a spec or data sheet?

- Unfortunately I don’t have a spec sheet yet, but here are some sheets for your review :

https://drive.google.com/open?id=0B3Y6uRJtUUhHVFhOOUhXUXJLVjA

https://drive.google.com/open?id=0B3Y6uRJtUUhHTXl3R2Z1RFYwNUk

What is the maximum resolution possible with the laser?

- With resolution, are you referring to DPI? The max DPI you can achieve is 1000dpi.

Can you do gradient engraves by changing focal length and/or power during engraving?

- You can do greyscale engraving with this machine and software. However, a glass CO2 laser does not modulate power on the fly. You are able to get greyscale engraving with pixel density; the closer the pixels are together, the darker the image.

I presume the water cooling is not contained within the machine, is that right?

- Correct, water cooling is an external device connected to the back of the machine.

I saw that you offer an option with some sort of air filtration. Do you have any more information regarding that?

- We have two options for fume handling; a standard exhaust fan, or the fume extractor. The exhaust fan is a standard blower that pulls the smoke and debris from the bed of the machine and vents it outside. The fume extractor is for indoor venting as it has different filters within the extractor. We offer different sizes depending on the size of the machine and how often you plan on running the machine as well. For our Muse, we suggest either the Small or Medium.

https://drive.google.com/open?id=0B3Y6uRJtUUhHVGZ5Zkw5N05JNUk

https://drive.google.com/open?id=0B3Y6uRJtUUhHaHdteTNDZlRnWFU

Is the rotary attachment included or on top of the purchase price?

- The rotary is not included in the price, but we do have it as an option. The rotary should be ready for shipment next month and is going to be $675.

When choosing a company to purchase from, one of the most important things to remember is that a laser cutter is a complicated device which appears deceivingly simple. In 2012 we launched our 5th gen hobby laser designed for makers by makers. Despite 3 years experience of designing and selling other lasers (the company was founded in 2009), the first prototypes admittedly had their issues. It took us 2 additional years to perfect the device and we have since sold thousands of these machines and know what makes a reliable system that just works. Our MUSE builds on 7 years of experience and incorporates the improvements we’ve designed after understanding years of laser operation. Today FSL has over 60 employees spread over a 2 building campus in Las Vegas.

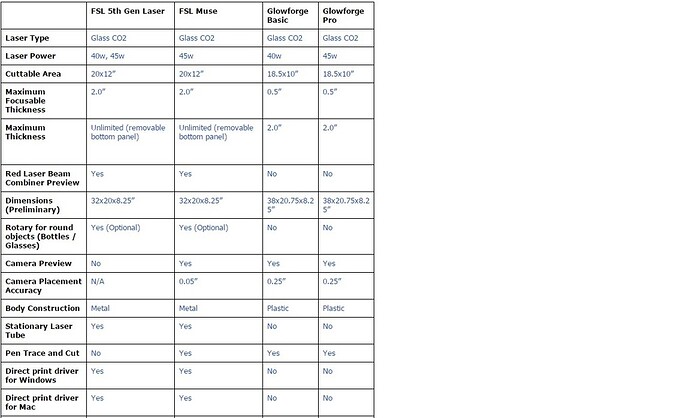

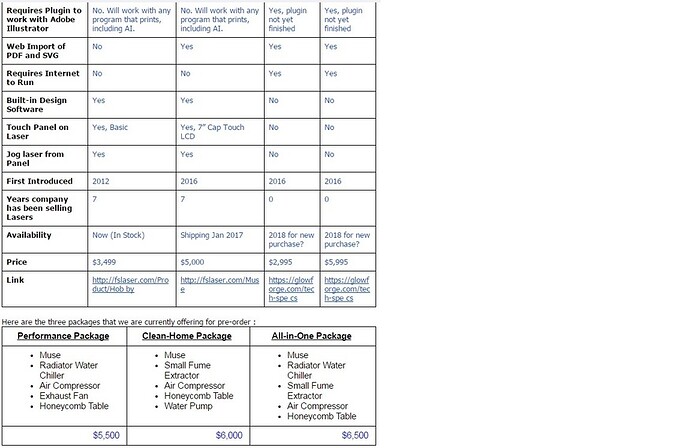

Here is the following information you have requested. Please note since the Glowforge is not shipping yet then the specs on Glowforge are best guess only and taken from these two links: https://glowforge.com/tech-spe cs https://community.glowforge.co m/t/information-on-pre-release -units/3590

While think any sort of innovation in the field that helps makers make stuff is great, we’ve seen some questionable design decisions by the Glowforge team that goes against the things that’ve we’ve painstakingly learned. While it may change, the Glowforge appears to move the laser tube on the Y gantry. Laser tubes are designed to be stationary. The high voltage wire is not designed to be constantly flexed and moved quickly. The tube is made from glass and is subject to break if constantly moved. We believe this may have reliability issues.

Secondly Glowforge appears to be made from a plastic case. Lasers cut plastic. This appears to be a safety issue. Thirdly, Glowforge requires their users to be connected to the internet to run the lasers. From experience, FSL knows many of their users will store their laser in their garages or workshop away from the internet so has designed all their machines to be run without internet connections.

Thirdly, the Glowforge can only focus on 0.5” and accommodate materials up to 2” thick. At FSL we know the most exciting applications are cutting and engraving objects that don’t fit inside the laser. With our patented removable bottom (US20140014634) you can even cut/engrave things like tables and floors. With our optional riser and rotary attachments, you can engrave wine glasses, bottles, pens and bats.

The FSL MUSE has all the advantages of web based applications such as nothing to install and interoperability between operating systems such as Mac, Linux, and Windows. The MUSE achieves this through having an internal offline capable web server built in. You just browse to the machines local webpage and run it.

FSL’s direct print driver is software we have developed over the last 7 years. This is something that sets our lasers apart from the rest of the competition. The laser appears as a regular print

driver. Glowforge appears to rely only an Adobe Illustrator plugin for example (which is not available yet) but likely would need to be rewritten if a new version of AI were to be introduced. FSL’s direct print technology, you just use the File/Print feature in any program including Adobe Illustrator.

One of the most common programs used with laser cutters is CorelDraw. Since 2009, CorelDraw introduced X4 (2008), X5 (2010), X6 (2012), X7 (2014), X8 (2016). Windows has evolved from Windows XP to Vista, 7, 8, 8.1 and 10. Because the laser appears just like a regular printer, the FSL print driver has stood the test of time and appeared flawlessly with all programs through the years past, present and future.

With MUSE, you have the best of both worlds, use the direct print driver or the web interface. But all the conveniences of direct printing such as any program compatibility (print even and vector cut from MS Word) is available to you without software version specific plugins.

FSL MUSE’s camera’s system has been developed and tested over the last year. All the great features of placement preview and pen trace/cut are available (even without an internet connection). However, FSL knows the most accurate placement is still to use an inline red dot beam combiner which travels the exact same path as the invisible beam. With the included beam combiner, you can run your job in simulation mode just in case of software hiccups. We understand your top priority is getting your job done and that is what FSL has designed the MUSE to do - just work.

We’d love for you to come and see the MUSE - please let me know if you’d like a demo in Las Vegas office or come visit us at CES this year in Las Vegas. We hope you will join us and be part of the FSL family. Please let us know if you have any additional questions.

- table image here -

How does the MUSE work?

The MUSE will have a camera located on the laser head. When you turn the laser on, it will “Auto-Home” by moving to the top right corner to activate the limit switches, and then it will position itself in the top left corner of the machine.

Let’s say you want to custom engrave a wooden plaque with your signature. First, you want to get a white piece of paper, and sign it with a black marker / pen. You want to use black on white as it creates the highest contrast and is easiest to convert.

Place the signed piece of paper in the bed (anywhere you’d like) and then place the wooden piece in the bed as well (anywhere you’d like). Now you want to scan your work area by telling the laser to start taking pictures by selecting the camera button. The MUSE will now take nine total pictures of your work area: three top, three middle, and three bottom. The reason this happens is because you have a camera that is clearly focused to the surface of your object and can stitch the pictures together, to make one large high res image, as opposed to a fisheye lens that will lose quality on the outside edges of the bed.

After it takes the pictures, you can see your work area and objects in the software. From here, you could import designs to place on the object you want to engrave. However, since we want to use our own signature, we’re going to crop out our signature, and it will convert it into a design. That design can now be dragged to wherever you want the laser to engrave it at. So we will drag that design onto the wooden plaque, position it how we want it to look, and we will change the settings for that engraving.

Once we are all set, you can hit “play” and the laser will move where you positioned that drawing (on top of the plaque) and will start engraving at the settings you told it to fire at.

I hope this helps and gets you excited for our upcoming MUSE. We’re excited for the release of the MUSE and we can’t wait to share it with you!

Where it says -table here - there was a table that couldn’t be copied, so I’m attaching 2 screenshots.

Edit was to swap the two images, as they were uploaded in the wrong order 1st time around.

Gosh, their pitch certainly gives  a lot of time and attention. Did you even mention them to FS in your inquiry?

a lot of time and attention. Did you even mention them to FS in your inquiry?

Yea, I told them I had a pro on pre order and wanted to compare the two.

Just as a side note, they sent me an email yesterday starting with Hello Robbert, my name is not Robbert and not even close…

I have to say, from what we have seen to date with the GF camera, it appears FSL approach of stitching together 9 images might be superior than the complicated corrections required for the fisheye lens… you would think if it that simple to correct it would have been done by now… although it has been mentioned that the head camera will add accuracy, again it clearly is not that easy to implement otherwise it would be working today.

Just hoping that this is all sorted by the time shipping starts…

They also can’t count. They had two “thirdly’s”.

Okay, that makes the response a little less awful. IMO

They live among us!?

At least they replied to you @vagozs. I have used there website question / info form several times and never gotten a reply. I signed up for email notifications when the Muse was first advertised and heard nothing, then I asked a series of questions when it was introduced, head nothing again (can you hear nothing twice?, or is that logically impossible?)

Maybe I should change my name to Robbert!!! That might get answers to my questions :-)))

If they are, and they are reading this, and they want to send me a FREE Muse to test and show off to you guys, and potentially wow you with the quality…

I would accept. For science.