Dug the trench for 100amp service as well

Great idea!

I’ve been procrastinating running power to my shed. I think it’s time.

I need to get power out to my shed as well.

Luckily the price of copper is lower than in the past. When I ran the power out to the sub panel in my Garage, and then a line from it to the far corner for my welder the price of wire was like at an all time high.

over 100 bucks for the run for the welder at the time. I had to make the sad face.

Geat idea ! Looks like you may have trouble squeezing between the planer sander and drill press to use your Band saw though…

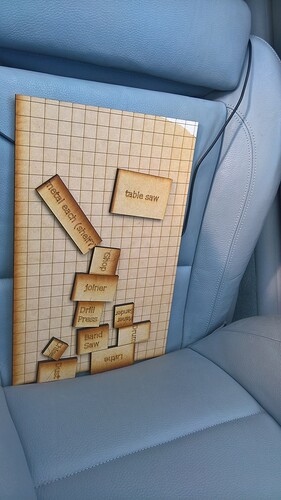

I just moved into a new workshop (4x the space as before—I’m in heaven) and everything is still piled into the corner while I try to figure out where things go. This idea is going to help immensely!

Great Idea! But I think your layout needs a little work

I’m about to do some shop remodeling, this will help a lot. Could also print out a guide to show the working area a person needs and slide it around the board to make sure you have good clearances.

Ya this was a rush job between morning shower and driving up to help did. So I did not do swing space but that’s easy to do in head

Ya know. in the olden days you had to use graph paper and paper cutouts of the machinery.

It is amazing how trivial it has become to just cut something out with the laser. Last night my wife asked me for the 10th time, “What is this key for?”. 15 minutes later it had a hardwood tag with “Storage Unit” engraved on it.

Now I have to resist the desire to build a 3D scale model—walls, removable roof, etc. They’re only a few more sheets of material, right? Some simple cuts for windows?