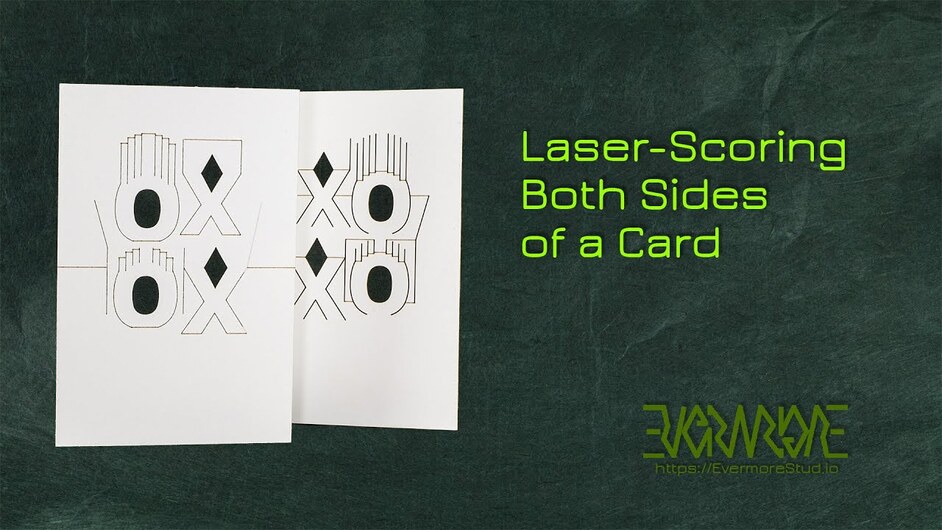

I have had several people ask me about how to align score lines on the reverse of cards and other paper art pieces with the Glowforge. So, I made a video of one way to do it. This is essentially a basic jigging technique that can also work with other materials.

Congratulations @evermorian, this will be a great assist for those of us who love making kirigami. Thanks for the tutorial!

Excellent, thank you!

Thank you very much

Thank you for posting!

Gotta say… I never watch laser cutting tutorial videos. But yours intrigued me. And it was just great! I encourage more!

Thanks you! I’ve got a few more in the (very slow) works.

Excellent explanation. Helps me immensly.

Isn’t it possible to eliminate the plastic right angle step by simply removing the blank card stock from the middle of the second sheet, then putting the previously cut cards into the rectangular hole? Better yet, why cut a second sheet at all? Simply flip the cards over in their original 4 holes and the adhesive sheet will hold them down in the proper location. No chance of messing up the alignment with the plastic right angle, uses less material, and much faster…

What you are describing is the jig-in-place method I (and others) have discussed in other threads. I do that sometimes, too. I started to make a separate video showing that but, I was working with black stock and, it just didn’t show up well. I eventually shot a different project for that but, haven’t edited the video yet.

Because of kerf (the laser does not create an infinitely thin line (it burns away a bit of material to make a cut), the hole will be a little larger than the piece you removed from the hole. So, when you flip it over, it can be off by a bit. There is generally only about a millimeter of play in my experience but, it can matter for some things (many of my pop up card designs, for instance). You may be able to adjust the reverse side cuts to align to one corner (i.e., place all the kerf space in the opposite corner) and, get better accuracy. Sometimes that is fiddly, in my experience.

Often, I am cutting cards 8-up and, the holes in the stock after the cards are cut have a few millimeters of border. Those little strips of paper don’t stay in place well for the flipping. So, it is often easier to just run a bunch of cards with one side, set up a jig (perhaps one for multiple cards at once) and run the second side.

Both approaches are useful in different circumstances.

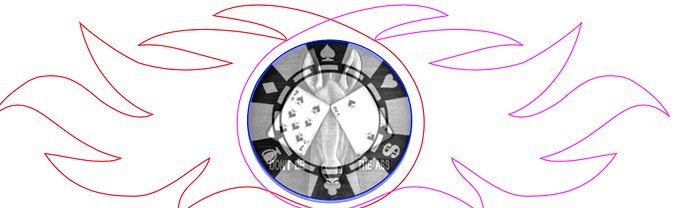

I have made mirrored cuts of irregular parts, so I can take out the first piece and flip it over.

Here’s one I’ve been working on for a while. The “flame” is only cut from one side, but the chip is engraved on both, so I cut a mirror of the flame so I can flip it over to engrave the other side.