I used the .06" on the first few. It cut just fine and fit the headband part of the shield but the little piece you grip on the bottom wouldn’t go on. I did change to the .03" thickness and that works great.

Here is the Prusa Face Shield RC3 in a glowforge-friendly format:

I had luck cutting 0.02" PETG on my Pro machine with 375 speed at full power.

I’m laser cutting some PETG from a local hackerspace to help with the face shields as well and I’d love to know more about your setup. Are you placing the sheets directly on the crumb tray or on a piece of draftboard? Are you cutting one at a time or multiple? Would love some advice so I can help contribute to the cause!

I tried printing my 0.020" PETG sheet from ProfessionalPlastics with the 250 speed, 100 power, and 1 pass and this is what I got:

Any suggestions on how to get rid of the color striations? I’ve tried it with the plastic attached (didn’t work, just created a ton of fumes and fused the plastic covering to the PETG) and without the plastic attached, and neither has worked.

Like everyone here, I hope that I can get my issue resolved as I’ve got hundreds of these face shields waiting to be shipped to some hospitals in need here in NY. Thank you all!

Try 375/Full. Works for me on 0.02" PETG using a pro machine. 250 is much too slow.

Are you using something underneath the PETG or are you placing it directly on the honeycomb tray?

Hello Nico,

Thank you for your help, but I figured out that the piece that I got from ProfessionalPlastics wasn’t actually PETG, but rather some shotty Polycarb. From my experience with Polycarb, it does tend to do that. I have other 0.03" PETG from another place that I had bought it from and that works with the settings I had mentioned earlier (on a Plus).

As for @bvp663, you should be putting the PETG directly on the honeycomb tray. Depending on the size of your PETG sheet, you might be able to cut your PETG sheet and put it in your GF so that 2 visors come out in one cut. Again, depends on your PETG sheet size and what design you are using.

Hello everyone! This is my first ever post but I have been reading all of yours for a few months now. Thank you to all who have shared settings, tips and tricks. They’ve been so helpful and I don’t think I’ve ever seen more supportive, generous folks as Glowforge owners! With many nurses in my family (one of whom is newly pregnant), I’m especially moved to help those on the front lines. I’ve seen and downloaded the specs for the Prusa face shield but I’ve also found one that consists of only one material. It seems easy enough so I thought I would share. Below is a link

I am cutting on the crumb tray, with magnets or bed pins holding the material down. I got the PETG cut into 12x12 squares so I am cutting one at a time. The shields are 240x240 mm (9,4x9.4 in) so they could fit 2 across if the material were wider. I am shooting for cutting a batch using 20 inch wide material in the pass through soon.

has anyone else had their pieces BREAK when they tried working with them after cutting? I’m wondering if I’m doing something wrong, or the material I ordered is bad, or if the PETG weakened after cutting. I did do multiple passes.

It sounds like you may have gotten acrylic instead of PETG.

That’s what I’m thinking too. Ah well - I can use it for other stuff…

Have you tried the design that Apple made public?

https://support.apple.com/en-us/HT211142

it looks good and is uses only PET and a strap

It looks pretty cool! I’ve been making the Prusa design, which uses a 3d printed frame, and a shield laser cut on the GlowForge. The all-sheet-designs are good, but they don’t give much room between the shield and the user’s head, so they don’t work if you need goggles or a larger mask. Great for people just wearing a thin mask, though!

I am also cutting shield for Prusa Face mask. Using 0.030 inch sheet PETG. I started with the settings here but then iterated the speed up and power down. I found a sweet spot at speed 300, power 80. My Svg has holes and outline separated, so i cut holes first then the outline.

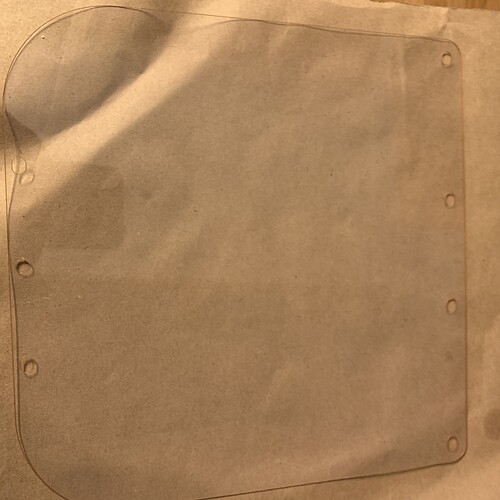

Could you post a picture of your 0.030 PETG cuts?

Here are some images, one with protective plastic still on the browning comes off with the protective plastic layer as you can see in second image.

Thanks much!