I just got my Glowforge on Saturday and needless to say I am struggling. I am trying to cut 1/4 African Mahogany. I have tried a number of settings and nothing works that well. I had success with 120 speed and full power on some of my pieces and then on other sections It didn’t cut through it. So tonight I tried 115 but that was too slow and caused flames so I quickly shut it down. I went back to the drawing board and tried 2 passes at 130… That worked but burns it up pretty bad. Needless to say I tried 5 or 6 different settings and never got the result I was hoping for. HELP ME PLEASE!!!

Welcome to the community!

Have you made sure your material is completely flat on the grates of the crumb tray (i.e. you don’t have any of the material on the lip of the crump tray?

You can try this camera alignment process that will also walk you through how to make sure the material is completely flat:

I feel your pain ![]() For a starter mahogany (even African mahogany) is not one species so even from the same source at a different time it is often really different. More than most woods.

For a starter mahogany (even African mahogany) is not one species so even from the same source at a different time it is often really different. More than most woods.

There is a good discussion and my “solution” here…

Some mahogany burns more easily than others, but not a good material for the inexperienced, Set your mahogany aside as you will want to try again, but try cherry or walnut first as Walnut especially is very forgiving.

Hi @chrismdoty. I’m sorry to hear that you’ve run into some issues with prints using 1/4" African Mahogany Hardwood. I see some fellow users have already offer some great tips and advice.

Proofgrade material and its masking is made to work well with Glowforge printers and consistency of cuts, engraves, and scores. However, you can use any material you like as long as it’s compatible with a CO2 laser. Options include many types of wood, leather, cloth, paper, stone, glass, and much more. We don’t support materials from other vendors because they can vary from piece to piece, especially with Mahogany Hardwood. I see @rtbdanforth posted some helpful advice to help you achieved your desired print results using that material.

Just in case, it can help to rule out any technical issues that could lead to any unexpected print results by running our Gift of Good Measure design using Proofgrade material with Proofgrade settings. This helps us gauge the current performance of your Glowforge under controlled conditions and starting point for any next troubleshooting steps.

Feel free to run the test print and post any results of the front and back of the material if it has any issues cutting through, or any other unexpected results. Thank you!

Thank you. It is cutting other items just fine. Unfortunately I really wanted this for a project I am doing. I was able to cut 90% of my project but running into issues on some parts of the wood. From what I am reading… The hardness of the wood could vary in my 8" X 12" piece. Gotta Love it!

Thank you for your reply. So to be clear you are running your engraves at full power? With my little experience I would think full speed with variable power would be better but perhaps that isn’t so?

Thanks

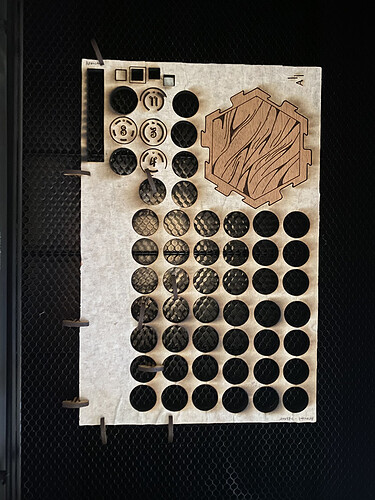

Here are my results with the Mahagony…

I cut a number of items on this project using 120 and for 80% of the cuts it worked great but on other spots it didn’t work well at all. The 120 is too slow at times though and causes flames.

For Example:

I need 4 more tokens (too many flames for my comfort) and the desert game piece (didn’t cut all the way through which I didn’t know until i took it out) So I am ready to give up on Mahogany but not until I get my pieces.

When running variable engraves white is no power and black is max power .and the grays are 254 percentages in between. Therefore if you are at less than max power there is less than max distance between the different grays. So you can make the max depth different by going faster or slower, and still keep that resolution. As I do a lot of relief 3d engraving I try and hold to max power for that reason. If you are engraving by vector or doing dots for a photograph, then the need is different, and lower power works as well.

The point of the standard tests is to have a standard that you keep. And while that may result in flames you must watch them like a hawk, and keep a spray bottle of water handy to put out the fire as soon as it finishes…

This is several tests I did/ You can see what was Mahogany and what was cherry…

The very bottom is red cedar I think.

Thank you for you help… At four days in, Im just trying to get it to cut let alone 3D Engraving! haha

Again thanks for your insights.

If there are flames the cut will not be as deep. anyplace you see a flame it is not likely to cut through there. Don’t know why but every time I have seen it ,it does not cut through as far.

Hi @chrismdoty It sounds like you’ve been continuing to get some great advice to help achieve your desired print results with this Mahogany wood, as well as other type of prints. Since this is occurring on a material from another vendor, I am going to move this to the Beyond the Manual section to keep your thread open and allow you to continue to get any further tips and advice from fellow owners. Note that advice in this section is unsupported and is not reviewed by Glowforge.

Feel free to create a new thread if you run into any other technical issues, and I’ll be happy to help out. Happy printing!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.