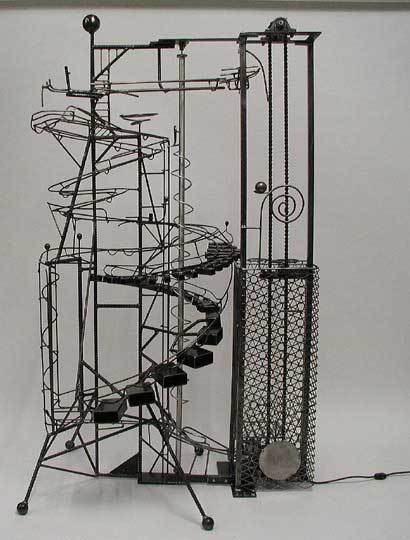

I am an artist specializing in sculpture and kinetic art, but I also do paintings, functional art, and custom art for movies and TV. Here are a few of my favorites.

Nice work! Welcome to the forums

Hubs would love that table!

I really like your work. Welcome to the group! I especially love the huge mobile and I also think the table is great. Thank yo for sharing everything.

Very cool steel art!

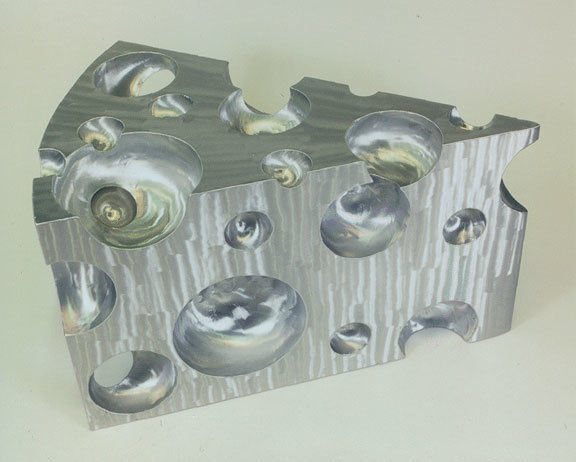

Love the cheese! The free form wall art is great! It looks like it would have a lot of gravity associated with it… like the glass top table. The gears contribute cool geometry, the gear circles and splines contrast well with the rectangle glass top. Heavy Metal!

I have had a lot of fun playing with textures on steel from sanding discs on an angle grinder. The light plays nicely across it as you move across the room.

Really outstanding Bruce! Thank you for sharing examples of your Inspiring artwork!

Your skill and experience are welcome additions to the forum community.

Very cool. Love the coffee table. Welcome

Just finished scanning three boxes of developed photos (with that cool portable scanner recommended by @morganstanfield) and came across several castings I did years ago. The vast majority of the casting I did was gold and silver with refractory molds that are destroyed each time, but I also experimented with permanent steel molds for casting silicon bronze.

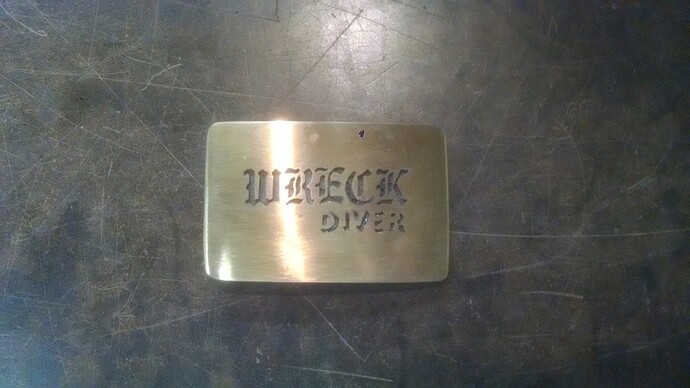

Bronze belt buckles I wore over the years, so they all show wear.

The Orca is enameled, and the background needs a cleaning and new patina

This one was not cast. The lettering was cut through with a coping saw and brazed to a backing.

These give an idea what was involved with making a steel mold.

an acetylene flame is used as a mold wash, that helps insulate the metal and helps release the casting. All inside edges are slightly beveled wider at the top to facilitate release.

The mold is bolted together and poured through the edge.

Another design that looks good on the bathroom wall. (the dark spot is a lens artifact)

This is another ocean creature I have an affinity for, the Moray eel;

He lives on a coral corallum (carbonate skeleton) with all of the beach combing treasures I have collected over the years.

The last one was a result of searching for barstools. I couldn’t find any that struck me, and the ones that were “OK” were $350 a pop.

I decided to embark on the journey of making my own. 3/16th" x 1-1/2" flat bar mild steel. I made bending jigs to build them matching.

Still haven’t seen anything I like better.

Ok people, I dug into the way-back machine to show a few more things, I would love to see more of your work!

I am so amazed that people can do such fine work. I really enjoy seeing the beautiful work that you have done. Your pieces are so well crafted. Thank you for sharing.

Very nice. I found a whole box of old rubber moulds for rodeo belt buckles at an antique store last week. I think you may have inspired me to fool around with one.

You’re so very accomplished! Really enjoying seeing your work…thank you!

This was all so fun to see. I love your work, and getting a sense of what you’ve been interested in over the years!

I’ve gotten to know a guy who makes a living scraping car parts for aluminum. Lots of fuel injectors and other parts that have to be disassembled by hand to recover the aluminum. He has a home-built foundry and makes aluminum ingots. We’ve been discussing casting some type of receiver hitch item, like this skull, or some belt buckles. Something about playing with fire and metal I guess. I like your stuff!

Thank you all

Odd, but this thread is about as close to a portfolio as I ever got. No pictures at all of most things I’ve done, and it was neat finding and sharing these.

It’s going to be great turning our creative selves loose with a laser!

@Brandon_R - great find! Someone poured a lot of themselves into those molds!

@marmak3261 - aluminum is one metal I have never cast, but have wanted to explore. Should be easier to work with a lower melting point, and no need to flux.

There is a design of chess pieces I would like to make, and casting round aluminum ingots to lathe is the plan.

You are right, “something about playing with fire and metal”!

WOW!! Amazing stuff, man. I am blown away…

Thank you!

I have been stunned by the work people have shared on this thread. Hoping to see and be inspired by more!

Inspired by @printolaser and others on this thread, I taught myself pewter casting to make this leaf/heart pendant necklace for my wife’s birthday last month.

It is only my 4th casting. I started out with a simple shape - her first initial on a simple background - just to learn with.

I created both designs in CorelDraw and then created cut paths in Vectric Aspire. I cut the paths on my CNC router on MDF.

I then sandwiched that piece of MDF with another piece that was not cut. Then I melted pieces of pewter with a blowtorch and poured it into the form.

The first casting didn’t come out good so I melted it down and tried again. Once I got the basic design cast reasonably well, I created the leaf/heart design by vectorizing a leaf clipart I bought some time back as part of a set. I manipulated it quite a bit to get the outline and veins to look right.

The hardest part was trying to get an eye hook in the top. I broke three micro drill bits before I gave up and soldered it onto the back.

My wife loved it. My next assignment is a moose pendant.

You might want to experiment with RTV silicone and making a rubber mold. You’ll have to switch your CNC model to a positive so the mold is negative. You can cast the hanging eye as part of it too because the rubber is somewhat flexible when you remove the piece. I find MDF burns at the temps I pour pewter at. Also see if you can get Britannic or English pewter - no lead content.

Funny, my current laser project started as a pewter one but I couldn’t get a decent mold with enough detail ![]()

Thanks for the suggestion. I may try that when I get around to creating the moose pendant.

So you can cast pewter into RTV?

Yep. It doesn’t last as long as baked silicone but no problems running them multiple times - just let them cool between uses to help lengthen their life.

I was doing little fantasy pewter chess sets for my kids and others. A previous “obsession” when I wanted to know how to do it (I was casting bullets for reloading at the time so it wasn’t a big equipment expense).

I’m doing a boatload of LED plaques for a submariner’s reunion that I was originally going to do in pewter. They had a 5x5in bas relief ships plaque that I used to make a couple molds from but the original was a copy of a copy so it didn’t mold well. I digitized the design and added the sub itself and the ship’s crew’s motto (they official one is on the seal  ). In fact I’m babysitting the laser now as it finishes the first 20.

). In fact I’m babysitting the laser now as it finishes the first 20.