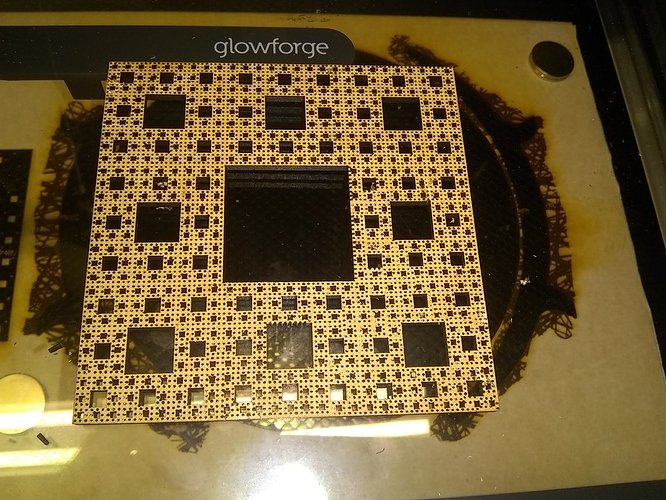

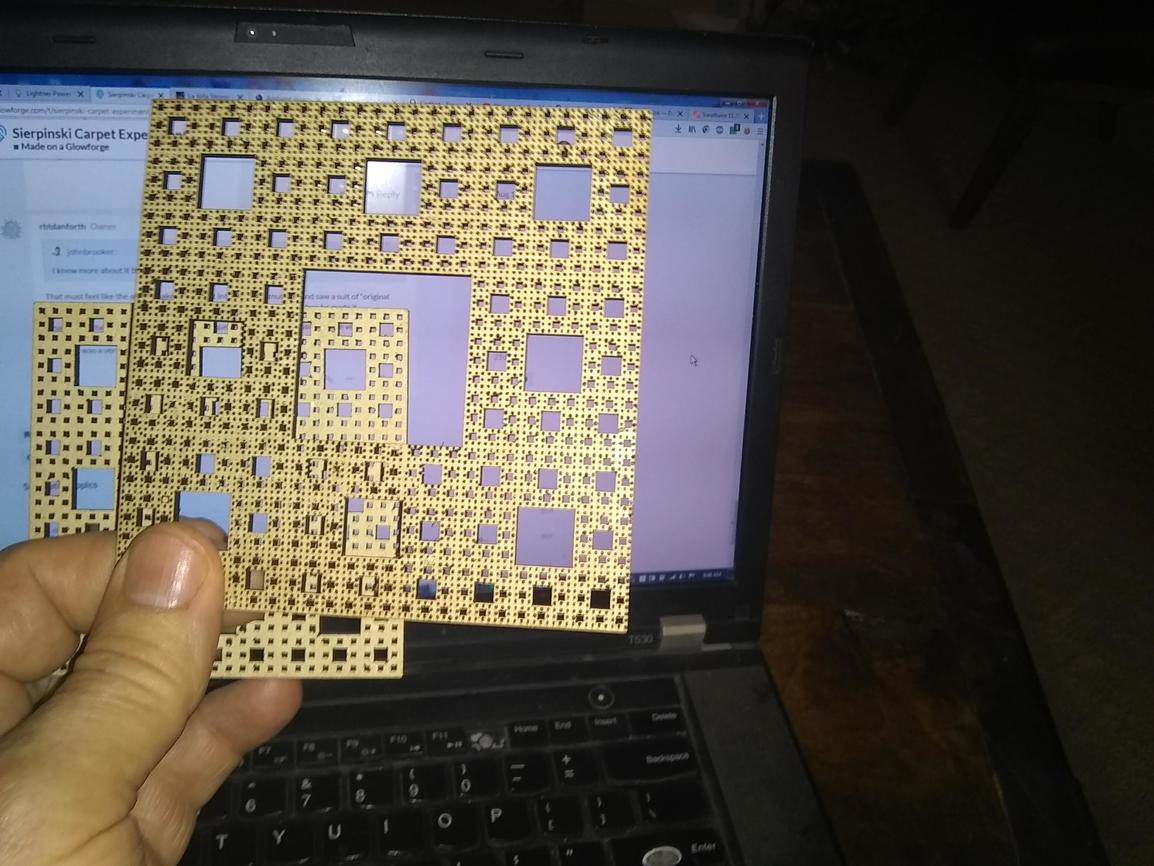

Had to take my Sierpinski Carpet Experiment from level “4” to level “5”. One more set of extra-tiny holes. The precision of the Glowforge laser continues to amaze me!

Used GP medium draftboard with ~30 minute cut time. Removing the paper backing is tedious but 100% of the holes show perfectly now.