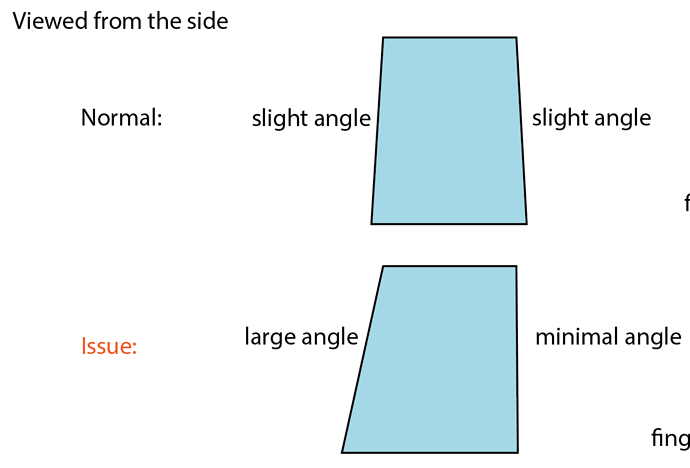

Thanks, I’m aware the kerf is cone-shaped and that it will never cut perfect squares. Did you get a chance to see my second diagram? My prints are fine when the angle (say 5 degrees) is the same on both sides. However, it is tilted much further to one side (10 degrees) than the other (0 degrees). This is causing issues with the finger-joint boxes, and is likely a symptom of a bigger issue.

I’ve printed the same design thousands of times, and it comes out perfectly on my other machine. Therefore I’m very certain it is a machine issue and not a misunderstanding of physics.