Has anyone made an SMD solder mask stencil with a Glowforge - and if you have, do you have any suggestions for methods or materials. My PCBs are designed in Eagle.

How thick/thin are your traces? Othermill has some good guidelines to design traces wide enough for small bits, but they are still far larger than most SMD components need…

I was thinking that if I were to try with othermill-sized traces, I would try to find acetate sheets so they mimic the thin stamped sheet metal I’ve used before, but then look for other extremely thin miscellaneous stock plastics to aim for metering the right volume of solder… Sorry somewhat inconclusive for you, but depending on acetate’s laserability-without-death, it could be a good starting point!

Adafruit demonstrates a process using kapton tape. They even account for kerf.

Sheet mylar is good for this kind of application.

It cuts well and holds up to repeated use.

Many thanks - I plan to try 4mm mylar - Pololu offer a service making them in this material. The boards are designed for milling (I have a Carbide 3D Nomad).

Many thanks - A brilliant tutorial.

I did both stencils and a jig with 4 mil mylar. Big writeup here:

http://www.riderx.info/easy-pcb-stencil-creation-and-alignment/

Thanks so much - and very timely - I finally got my Glow forge working this month.

I hope that (mm) was a typo!

Yep

Nice, detailed writeup! It seems to have everything except the power settings you used  What did you find worked for the 4mil mylar?

What did you find worked for the 4mil mylar?

A reminder: Discussion of non-PG settings will require that this thread be moved to Beyond the manual.

If you don’t know why that is, please read the FAQ. It is located in the upper right of this screen under the three line “hamburger menu”.

I might have them written down someplace but I don’t have them handy right now. I did an engrave and just played around until I dot a result that worked.

The edges of the engrave are slightly thickened over 4 mil; probably to 6-8 mil. Seemed to be just fine for the solder paste.

Ah, gotcha. Thanks for the reminder.

I created my SMD solder mask using the info in this thread and from @eric_gunnerson…I can’t wait to put it to use this weekend! Hopefully gone are the days of using a syringe to add globs of paste to my boards!!

Thank you!!!

Cool!

There’s a short video of me making some boards here:

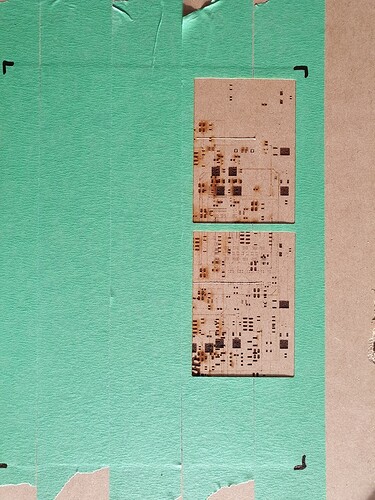

Many thanks Eric, a great video. Since my first posting I have made many stencils using the method you suggested. I find that it works better when the mylar is fully covered by masking tape before cutting. This reduces the tendency of the mylar to form microscopic blobs on the edge of the cut and allows masks with smaller clearances. In this image the mylar is under the green tape on an MDF base board.