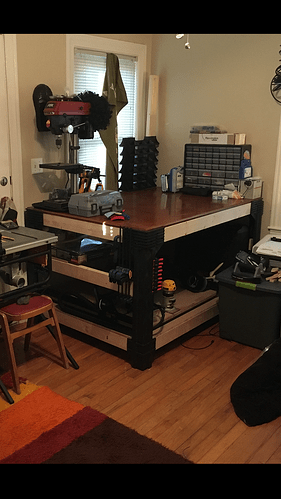

It’s a custom made table from a kit by 2x4 basics. It’s pretty sweet and makes a really sturdy yet inexpensive table. You just supply the wood and build to the size you want. I made the tops out of 3/4in mdf with a couple coats of shellac. The rest is 2x4s. It comes with stuff for a shelving system too which isn’t in the last picture. I’ll see if I can upload another shot when I get back to my computer.

Awesome thanks. Just ordered it. Super cheap option. And at some point I will make a torsion box top, but this solves a big startup issue.

Spike, you may want to look into cutting gold leaf as I believe it reflects CO2 laser (typical laser cutter mirrors are gold plated) and would reflect the laser either back into itself or worse out of the cutter

@troy_cording, Yeah, it was more of a joke. but good to know.

Just to point out (to avoid freaking people out who stumble on this in the future) you do not have to worry about reflecting the laser beam out of the glowforge. The glass top will absorb the beam.

Rabbet hole! Arf!

I’m on holiday schedule so a little less available until Jan 5, but as noted above, a glowforge cannot cut metaal.

I’m not sure I would trust that epilog link above too much for “what can be cut”. For instance, it lists “plastic” and says it can be cut, but you most definitely don’t want to cut certain common plastics, like PVC (gives off chlorine gas) and others are iffy (ABS, Nylon, and PP can be cut, but are melty). Ditto for fabrics. A little more detail is needed…

Anyway, a good joint community project will undoubtedly be pooling our experiences with suppliers and materials.

It’s a rough list for sure. But that’s my original point. I believe it’s unrealistic to expect Glowforge to provide a definitive lists of materials that you can cut for just those performance and legal reasons. There are nuances in all but the most organic materials. Even wood or plywood might have little note stars***depending the type of exotic wood or the makeup of the plywood glue.

As others have said, there’s no way a Glowforge (and probably no laser cutter under a couple hundred watts) is going to be able to cut metal. This page on the FAQ covers materials that it can cut and engrave, and was there when we booked our order in September.

The Glowforge can be used for etching and engraving of some metals. Anodized aluminum is what springs to my mind right away, things like the back of an iPhone or MacBook or colored dog tag. Here’s a pic of some tags I made a couple years back (on aTrotec laser) as an example… what the laser basically is doing is etching/burning the anodized coating that’s on the metal.

One other thing you may be able to do is look at other metal coatings that you could use in conjunction with a Glowforge. Laserbits carries a lot of interesting materials and supplies that are used with various cutters, and they’ve got a metal marking solution that can be used to put designs and labels onto other metal objects that might otherwise not be usable (I’ve never used the metal marking material myself, so I couldn’t tell you how easy or difficult it is to work with).

For jobs that require precision cutting of metal shapes, you could look into outsourcing to a company that does metal laser cutting, or that has waterjet services. You may also find a makerspace in your area that has a waterjet. Those are much more bulky and expensive to operate than a laser cutter, but can achieve some really great results on anything from sheet metal to thick steel plate and even stone blocks.

I hope that info helps!

Yes, the members will be building a list. And with any luck a full database with as much info as we can find and full settings.

wow looks sexy!

you can get a pretty good cnc plasma cutter for pretty cheap to cut metals. I love my 4’x4’ table made by EZ Plasma. you can get really fine/intricate cuts by adjusting the amps on the power supply, the head distance (torch head controller), cut speed, etc.

I plan to use the Glowforge and plasma side by side. metal laser cutters aren’t cost effective for me yet. plasma is cheap, fast, and accurate if you know how to use it. But the plasma wont’ cut plastics, wood, or leather…thus the GF.

Um, on Google, it’s showing as about $28000. Torchmate has one of those in the $6000 range. Unless I am missing what plasma you bought.

I bought mine for $14,000 (including power supply, torch, computer and software). I looked at the torchmate, but the table was not as good of quality and everything else was pretty much the same so I went with EZ plasma and have not been disappointed. it has put up with some serious use (and abuse).

I’d never heard of Rowmark before, but that stuff looks really cool. It seems a lot of there stuff is actually two color ABS instead of acrylic - which makes me wonder. What if I 3D printed a flat sheet, and then with another nozzle printed another color right on top of that - then follow that up with acetone smoothing. I wonder how laserable that would be (to laser off the top color and expose the lower color).

Turns out ABS is bad to cut in laser cutters from what I’ve read. (Even Rowmark actually mentions the possibility of fire with their ABS core products) It seems for their laser products they use a thin layer of acrylic on top of a thicker sheet of ABS with the idea that the laser is only suppose to burn the acrylic off but not ignite the ABS. The idea still works though if I can get some acrylic filament - at $17 a sheet and it’s only .003" of acrylic on top of .05" of ABS I think even paying $50 for 1Kg of acrylic filament I would still come out ahead cost wise. Would it be as spot on accurate/good as Rowmark’s stuff? Probably not - but half the fun is making something yourself right?

The brass or gold rowmark stuff ( I have a sample) is stated to be all acrylic and definitely vector cuttable.

I will make a sandwich so that I can simulate metal from either side. I suppose that I will touch up the edges with model lacquer.

First as stated above…a non commercial CO2 laser alone can NOT cut metal.

And second, the Rowmark laserable material is 2 ply acrylic. ABS should not be cut on a laser as it produces cyanide gas.

I’ve been working with a laser cutter for over 15 years…

This what I use instead of metal on plaques.