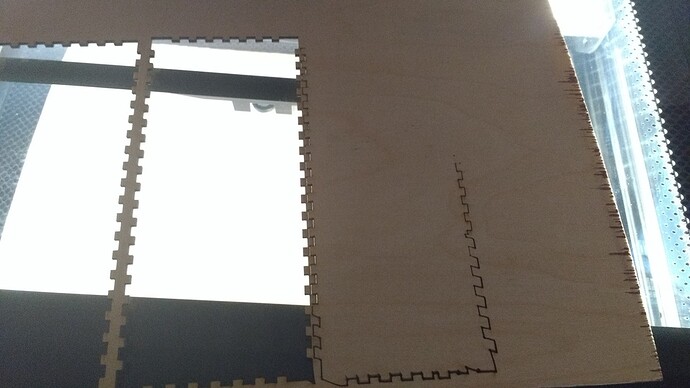

It sounded like a belt skipped. If it happens again I will update.

I wanted to document this, I choose not to put it into the problems and support as it is not PG material. I will probably put something there if it happens again.

Strange. It’s as if at least one of the Y axis motors continued to move during those horizontal cuts even though they should have been braking (assuming the lines were parallel to the X axis).

Off topic…

This thread title reminds me of the post about the first (publically announced) beta unit being delivered to @jkopel.

WOW! That was nearly 600 days ago.

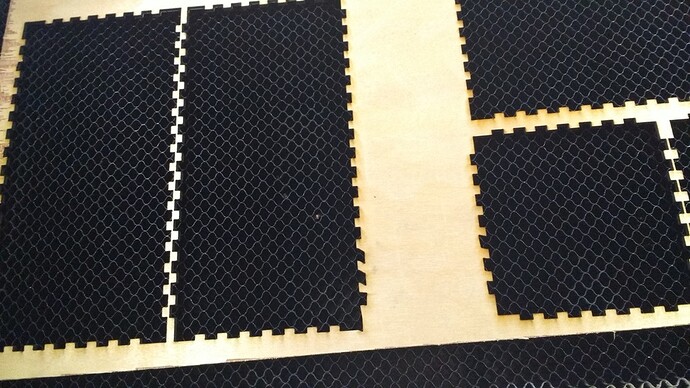

So I ran into the issue again. I am gonna look at my design and swap over to proofgrade material.

I am using 150 speed, full power.

For the record, I still really hate that I have to use proof grade for anything support related…

So, I redid everything with medium draft board and it has worked so far.

But whatever medium you use it would make no difference to whether the GF is cutting in a straight line or not!

Yes this is total nonsense unless they state this is only a laser cutter for cutting PG materials. Every other laser cutter on the market does not need special materials in order to cut straight. If you cut it again on PG and it works what does that prove? Something wrong with your plywood, I don’t think so. A complete failure of logic on their fault finding script.

Looks like perhaps the head came loose on its mountings and then snapped in again.

The head coming lose does actually make a bit of sense

That turns out not to be the case. In some cases, Support will ask users to try on PG, but there is absolutely nothing prohibiting or even discouraging you from posting this in the correct category – the one that’s monitored by support.

The issue you’re experiencing is clearly not related to the material used, so asking you to test on PG, if they asked you to do so, wouldn’t be relevant in this case.

I’m not surprised you wrote this, but it’s false-to-fact.

Edited for clarification…

I have no idea what false-to-fact means.

A fact is they will only provide support for PG materials and always ask for the fault to be reproduced on PG draft board.

Another fact is a lot of faults have nothing to do with the material on the bed. They are faults in the GF or its software. And motion path faults like this fall into that class.

In this case the material would not be the issue…this would be purely a mechanical or software glitch…

So I agree with @palmercr. No logic in why it would cut only on proofgrade.

Sort of like calling HP printers and telling them that my picture didnt print out correctly on my printer, it had horizontal lines throughout, and support saying try green paper instead of the blue. Lol

This needs to be addressed with support…you dont have to post it in the forum…just email them directly.

I second that opinion! If it’s an issue about, say, cutting all the way through, then requiring Proofgrade is reasonable, but not for a mechanical/software issue.

Have sent plenty of problem reports to Support where I was not asked to recreate on non-PG. But if there is any possibility that a problem could be S/W related then printing on PG might help narrow down the S/W path leading to the issue. Maybe not in this case, since it seems to be hardware, but most folks are never as smart as they think they are.

The worst customers are those that think they know what a problem isn’t.

True, they only provide support for material-related problems for PG, but that’s not the case here.

They do not always ask for replication on PG. That’s simply not true.

There are many cases where they have requested replication on PG when it is clearly nothing to do with the material. In fact nearly all cases like this one where the path has gone wrong. People argue it could be a bug brought on by non PG settings but the machine should function correctly with non PG settings. In fact it should function correctly with any setting it allows. Whether that gives good results or not is obviously material dependent. So any too deep, too shallow, too light, too dark, too melty or on fire problems it is reasonable not to support but motion problems should never need to be reproduced on PG.

Reading recently that Dan said they don’t support, document or encourage the use of manual settings is very disappointing. This must be the only laser company to do that.

He really said THAT???

Wow, where did @dan say that? The most i recall is that for non-PG material they couldn’t provide support for the results of “printing” because they hadn’t tested against that material so they couldn’t guarantee results. I’ve reported numerous issues upstream of the actual material, like this motion issue, and I’ve never had Glowforge support say that I needed to re-run a job on PG material. That’s not to say that others haven’t been asked to do so, of course…

“many” ≠ “always”

Link?