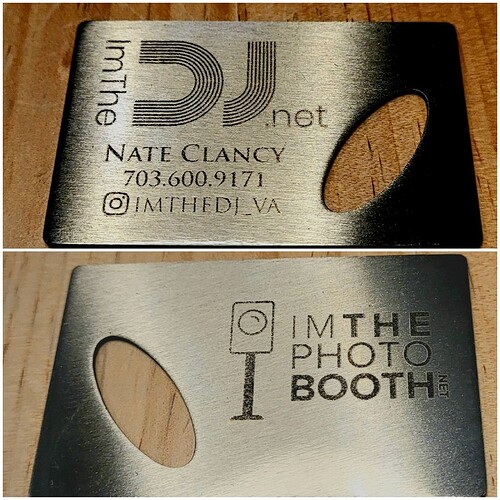

Made these for my husband. He’s a wedding DJ and has a bridal show coming up. I used Cermark using the Macbook setting. But wanted to know if Enduramark is better at making it darker ?

I would try different settings. Maybe make a test file or search the forum for one. Macbooks are aluminium. I would think the stainless steel would require a bit more power and time (less speed).

I’ve done stainless and gotten much darker blacks - solid, glossy and no breakup or dot patterns that show in yours. If your artwork is solid, then it’s the settings or the application of the Cermark.

I cleaned the stainless with denatured alcohol. Then I put on two coats of Cermark and let it dry per the instructions on the can (an hour or two maybe?).

Then I lasered it. My settings were much different than the Macbook silver settings. Much slower, vary power and lower LPI. PM me & I’ll share the settings or we can move this to Beyond the Manual and I’ll post my Cermark SS settings.

what settings did you use? I spray 3 layers of CRC Dry Molly (dry inbetween layers) then I use 150/FULL/340 lpi.

I moved the post to Beyond the Manual since that’s the only place we can discuss non PG settings.

I note that the steel you have has quite a pattern in it - so it’s possible you’ll never get a flat finish since it’s just changing the colour of the steel, not actually cutting into it. That being said, I’d try the settings that @danielsalce84 or @jamesdhatch suggested on a test block (just a square of black) being sure to change to vary power (as opposed to Convert to Dots or Convert to Pattern)

That’s not what happens with Cermark. That’s what happens with aluminum and the colored anodization layer.

Cermark actually fuses to the metal like toner does on paper in a laser printer. The unlasered Cermark is washed off. (Same is true of Dry Moly Lube sprays.)

Yes - that does not contradict what I said. You’re not cutting into the steel so there’s no risk in upping the amount of power transfered.

Actually there is. My first large scale (16x10") SS Cermark project actually warped 11ga stainless. I was lasering a patent award on the steel so there was a mix of text & drawings and I ended up having to reorder the “engrave” to do a paragraph at a time mixed with some of the drawing and bouncing back to the other column.