So … Some of this has been covered in other posts, but thought I’d share my stencil cutting tests here. I’m cutting stencils for creative use if that matters. And here is the spoiler alert:

My preferred stencil material from this test is Grafix Frosted Laser Craft Plastic, .010 thickness, for a sturdy stencil. For a thinner stencil, I like DuraLar Matte .005 Film.

Overall, Polyester sheet cuts more reliably than polypropylene. Polypropylene melts more. I tested 2 products that are technically an altered version of polypropylene - Yupo and DuraBright. I also tested a pure polypropylene (slightly thicker than other tests), and it melted at the edges severely (not going to be shown in images here).

UPDATE:

Note: I used a Seklema Multi-Mat under all plastics tested. It helps significantly with cutting plastic because it keeps the material off of the metal bed, which will heat and leave a mark. I did not mask any of the plastics, so if you mask your materials, keep that in mind.

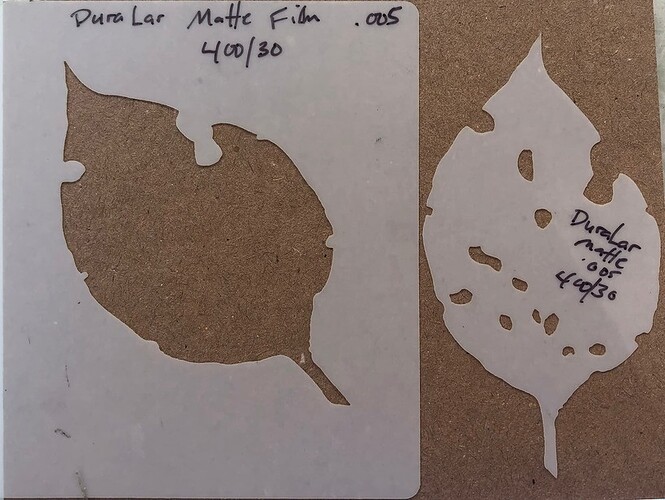

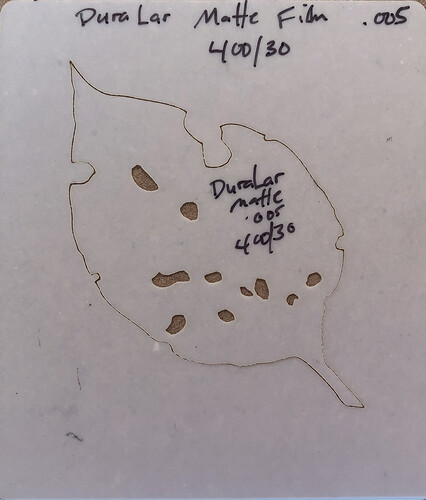

DuraLar Matte Film - .005

Cut acceptably well, with little of what I’m going to call “serration” at the edges ( a tiny bur like texture on the stencil edges - possibly the laser pulse). Speed 400 / Power 30.

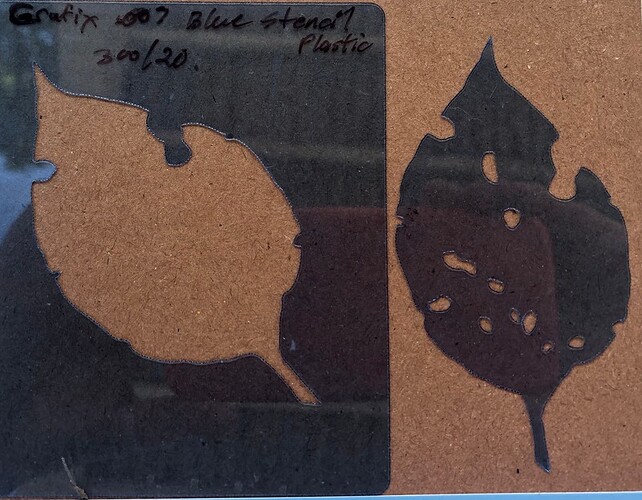

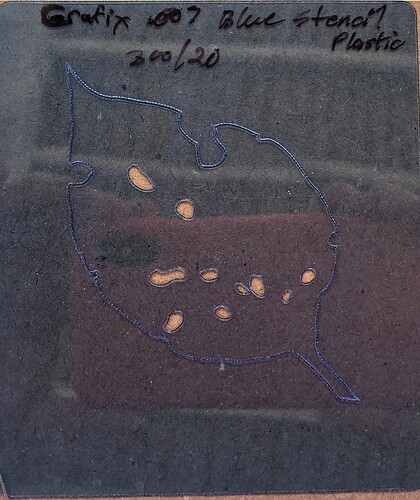

Grafix Blue Stencil Film - .007

Cut acceptably well, with little “serration” at the edges, the serration effect shows up the most in this photo due to the color of the material, but it’s about the same from a texture perspective across most of the materials I tested, with the exception of Yupo. NOTE: I also cut Grafix clear craft plastic .007 at the same speed and it performed the same as this stencil plastic. Speed 300 / Power 20.

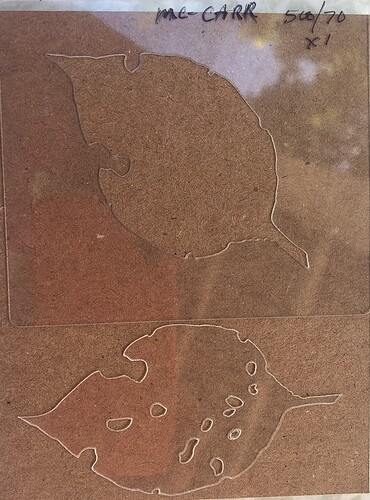

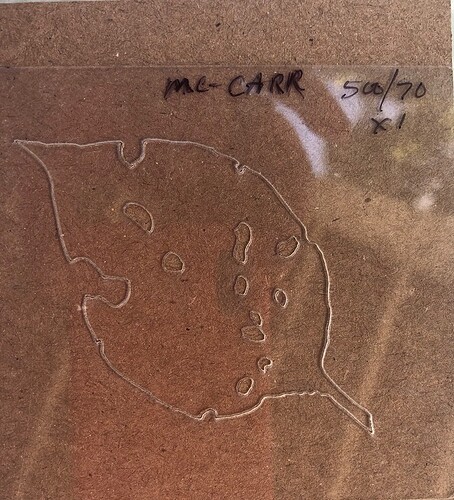

McMaster-Carr Polyester sheet - .010

Nice and sturdy, cuts nicely, but my choice isn’t clear plastic because it’s harder to see if you drop it. Speed 500 / Power 70

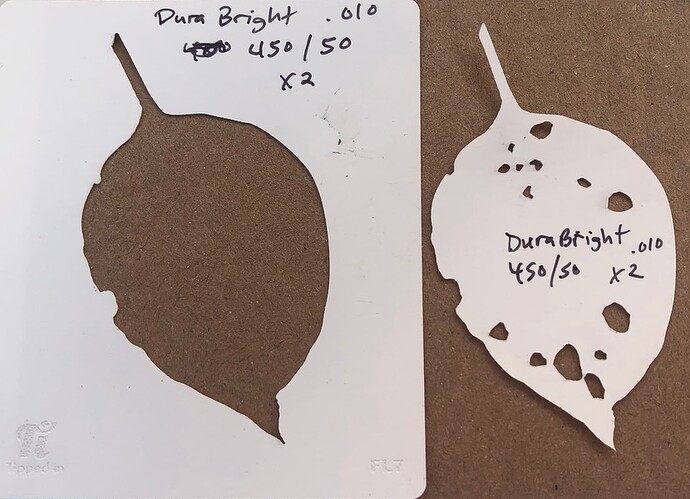

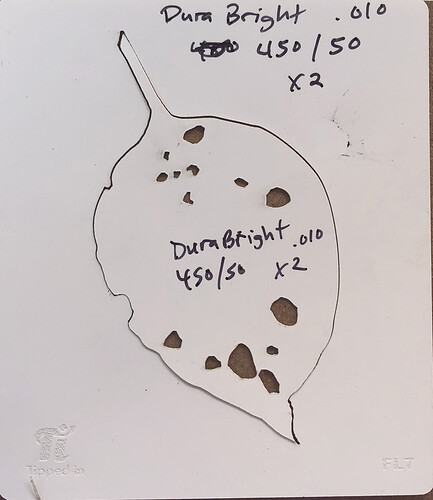

DuraBright White - .010

Cuts acceptably (for my purposes), but creates a slightly wider kerf due to melt, and leaves a bit more serration “fuzz”. This material is an altered version of Polypropylene, which tends to melt a bit more than polyester, but it behaves better than the Yupo product and is slightly less expensive at this time. It’s also Opaque – which may be an issue for some. Speed 450 / Power 50 - 2 passes.

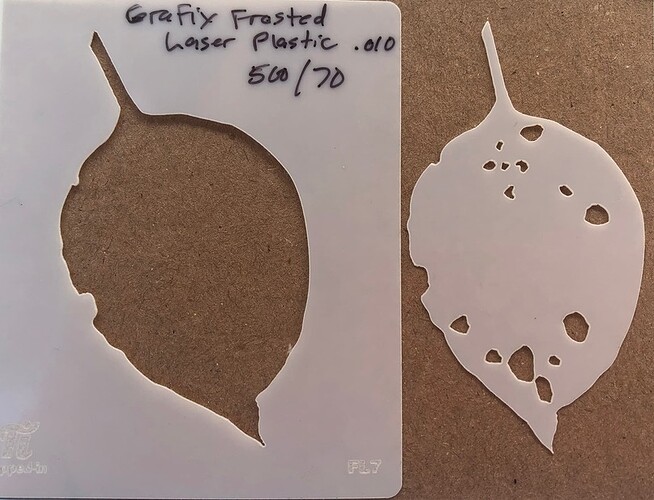

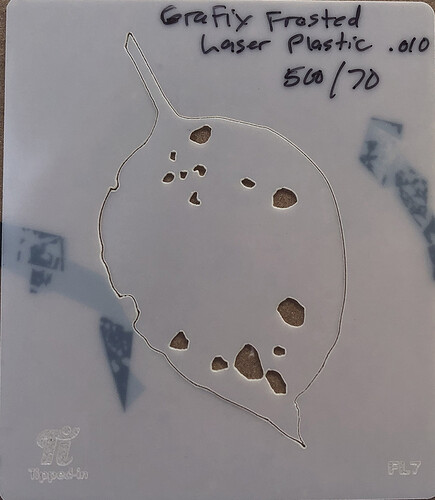

Grafix Frosted Laser Plastic - .010

In my opinion, this cut the best. Very close tolerance and the smoothest edges. It is a polyester film by Grafix, treated in some way for laser cutting. They state that you can stack it to cut multiples without sticking, but I have not tested this. Speed 500 / Power 70.

Update:

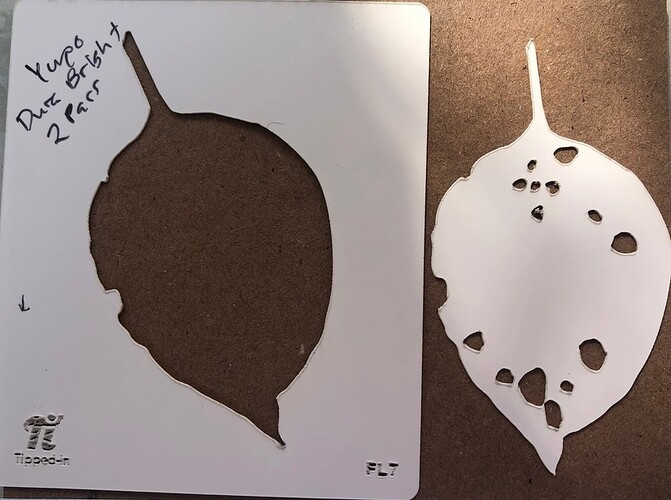

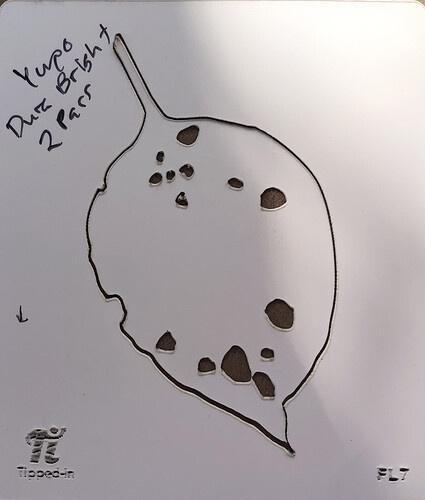

Yupo White .007 (74lb)

I forgot to add the photos of this one. It was not successful and this is just one of the setting tests – which I don’t have marked correctly on the image, sorry. I think I cut this at the DuraBright setting – but all other settings resulted in some version of this slight disaster (excess melting and/or serration). Not saying there isn’t a good setting for this one, I just gave up on it since I had other plastics I liked better anyway. ![]()