Vinyl venting session in support of the generalization of materials and assumptions from photos as opposed to the accompanying text.

Vinyl on.

Vinyl venting session in support of the generalization of materials and assumptions from photos as opposed to the accompanying text.

Vinyl on.

That is awesome.So your template is 18x10? I’m trying to wrap my head around it:-)

Yup! The template is 18x10 and the (0, 0) is at the (2.75, 6.75) of the actual bed of the glowforge.

The template in the photo is one I made in design space so it is not downloadable but I might make it in inkskape and will post it if so.

The grid I made with design space just has the lines at a 2" spacing because weeding 1" is a pain.

What a wonderful idea!

Be careful not to accidentally zap the grid, even a little lasering of vinyl creates corrosive fumes that will damage your GF and your lungs.

I actually love how much caution there is on this. I agree its best to be cautious.

The wavelength of the laser on the base of the glowforge is not something I personally am concerned on with outdoor vinyl, it is not enough to even burn through masking tape. I made sure to research the specific vinyl I use an I do not resort to generalizing material as all be the same if they have the same prefix. No where in my post do I provide all the instructions to just make it on your circuit with any vinyl you have around. I did that for the purpose of making sure that is not communicated…instead, I state that if someone wants to make it then I would use masking tape and draw the lines.

But no doubt, it is better to be overly cautious and I don’t want this post to suddenly make others think vinyl is safe to cut within .5 of the laser head (which it certainly is not and I do not advice). But this is why I state advice to use masking tape.

There has been a few photos from a while back of Glowforges that folk have been “slightly careless” and they are not for the faint of heart. One had a single cut of vinyl and after some time later looked like he had found it on a coral reef ![]()

No doubt that would be an issue with in the .5” of the laser head. The concentration of the beam at the base of the glowforge is certainly a topic but it was not the intent of this topic. I have updated my posted and censored the “v-word”.

Not all vinyl is vinyl.

Siser’s HTV (Heat Transfer Vinyl) is actually polyurethane.

Just like… not all laser printers use toner.

Very true

I think everyone can agree to make sure and know your material if you put it in the glowforge.

Me too.

@MyDogsThinkImCrazy do you think cutting it out of really thin masked acrylic would work? Then you could have lines as thin as you want. And once placed, mark the location an remove for the regular tray. What do you think?

And how did you get the grid to layout so straight when sticking it down?

True, though it would be a real trick to have used HTV in this particular project.

I think I am tracking what you are saying and I see no reason why it wouldn’t work. I am going to probably try a few different things and will report back with what I come up with

I getcha - in the case of this particular thread you’d have to get the heat press into the GF somehow to hit the base.

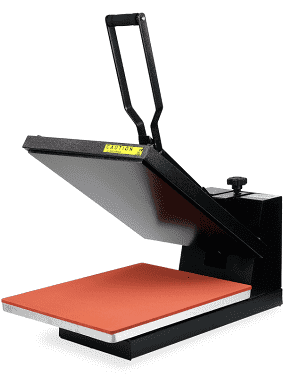

My heat press would fail  as it looks like this

as it looks like this

Lol, the circuit easy press comes in a lot of different sizes (I have a few) but my favorite is the circuit easy press mini, which is low cost and tiny. It actually is designed to be used to put HTV on your shoes and hats. I think this can fit…

You also do not have to use a heat press, you can use a house hold iron and teflon sheet.

But the points you are bringing up are great examples that support my statement from above that it is important to know your material. I appear to have a stronger understanding of adhesive and heat transfer vinyl then most but I still always look into the material I use.

So…one last try: Wavelength has nothing whatsoever to do with the issue.

The issue is that the laser still burns material even when it’s on the bottom of the machine. When you burn vinyl, even just a tiny bit, you release chloride gas that gets blown all over the inside of the machine and will gradually corrode and eventually destroy the electrical components.

One last try…not all vinyl is the same. Generalizing materials is not best practice. There are laser safe vinyls as we discussed above. I never stated the vinyl I use in my post and I never encouraged others to use vinyl. Even more so, I stated that although the grid I have at the base of my glowforge is useful, I am planning to switch to masking tape. I created this post to share information that I found valuable to the glowforge community. It is your choice to make assumptions from an image and negate the value in the information in the post.

What I was replying to was (as quoted in my response) your statement that since it was on the bottom of the machine you weren’t concerned with the laser interacting with it.

I am not disputing the fact that things that are not actually vinyl sometimes are labeled as vinyl. I am disputing your statement that the wavelength of the laser is somehow different outside 0.5" from the head than it is within 0.5" from the head, thus making the type of material used on the bottom of the machine irrelevant.