So tonight had to work on 2 prototypes for a set of “what really grinds my gears” problems in the OR (crap falls on the floor, and somehow in the last 2500 years of surgery we haven’t figured out a good way to have crap not fall on the floor - especially if it is hooked to a tube/wire)

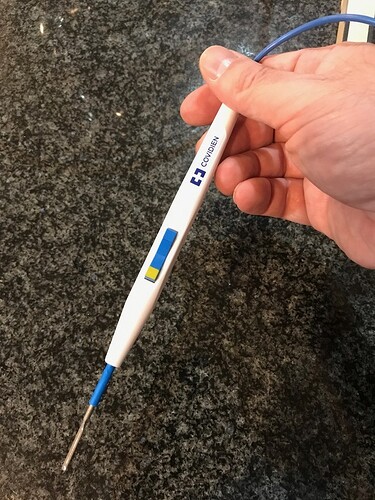

So first problem was with the device called the “Bovie” named after Dr. William Bovie (it’s also known as the Electrocautery) which is a RF arc knife/cautery that can either cut/cauterize or just cauterize. They are used in every type of invasive procedure, and are ubiquitous.

Well they come with the absolutely cheapest piece of crap (sorry if the guy who designed it is on the forum) holster made of injection molded nylon. It is utterly useless.

It’s a nice little shipping box, but it is so easy to knock it out, but hard to hit it when you aren’t looking to put the bovie in. And if you are using the extended tip (thoracic surgery) then it sticks more than 50% out of the box, and simply falls out (causing stoppage of the operation)…

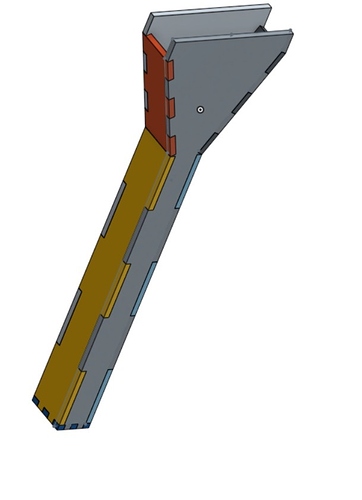

So decided to try a quick design to see if a funnel shape with a long tail would work better. The real one needs to be a little fancier with a few extra features, but 3D printing the final shape would take hours for an injection molding prototype for testing, so this took a few minutes to design.

Ran it through the Kiri:Moto output, into DXF and then into AI. Moved the parts around to fit in the piece of scrap birch ply, and printed.

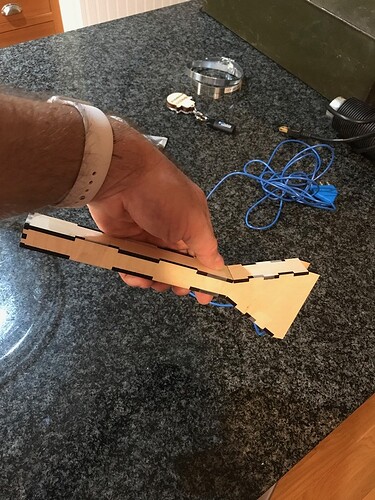

FAIL

Haha. Yeah, design for 1/8" proof grade and print on 1/4" scrap ply… Really, the tabs don’t fit? Sigh, well only 5 minutes wasted. So at least I could check that everything aligned (just not at once) and that the cuts were sane.

Yay

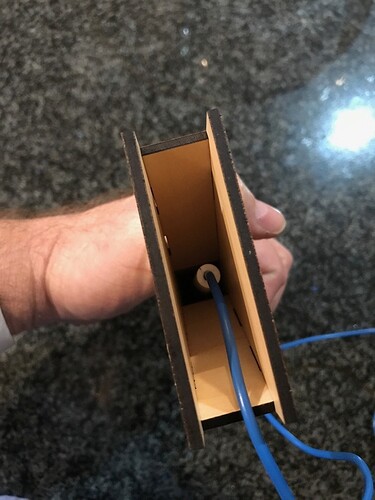

Recut it on proof grade 1/8" maple (and oops forgot to use the manual cut settings) but the automagic settings actually did just fine (if a bit smokier). A little scotch tape and testing in my kitchen, and it really works.

Easy to insert blind:

And doesn’t fall out when tipped (but removes easily)