I am a complete laser newbie. Everything I know on the topic, I have learned here on this forum. I have had my production Glowforge for 3 1/2 days.

My proofgrade materials didn’t come day one, so I snagged a small sheet of birch plywood from my big box and that’s primarily what I’ve been playing and learning on. I’ve used proofgrade acrylic that is a dream. I’m waiting on some adhesive before I show off the project that I’m working on with that. I’ve prototyped a bit on cardboard.

And here, I’ll show you what I’ve done with that Big Box Birch:

First off, I tried three levels of engraving for a photo. I’ll do this with hardwood instead of ply later and see if I get better results, which is my expectation.

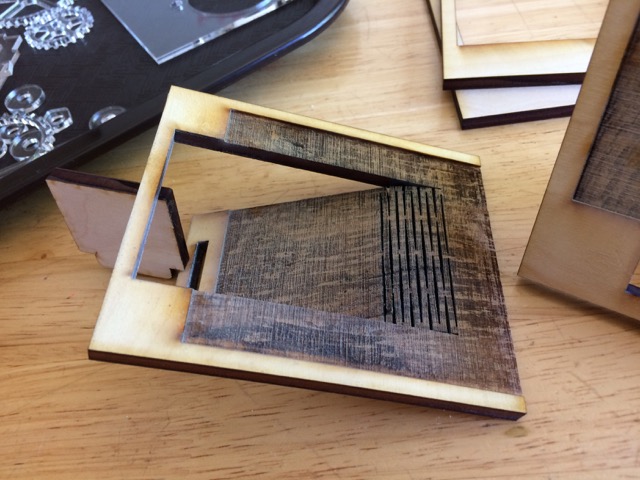

Glowforge includes some free files - mostly the things they were demonstrating at maker fair. This photo frame is a nice demo of engraving a pocket, living hinge, 3-d item with easy assembly, and so a great starter project. My BBB ply is thicker than proofgrade, so the tab didn’t fit; but I really love the living hinge and learned a lot playing with it.

I had previously made a file depicting a 1972 Jeep commando profile and wanted to affix it to a frame for a quick easy fathers day trinket. Dad and my brothers have these classic money pits automobiles.

The Jeep engraved pretty well. I wanted to see if a bigger frame would look better than the original size, and I experienced some principles there, too.

Close-up on the Jeep engraving. I’m really pleased with how well they came out for a quick “let’s see what happens” test.

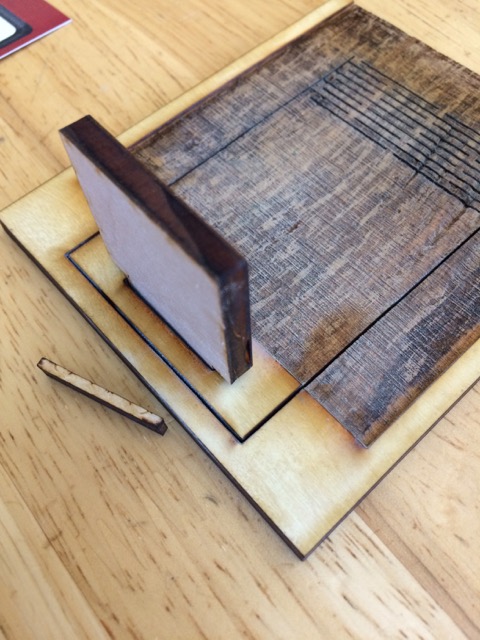

You can see that my BBB is thicker than proofgrade, and so the tab was the wrong size. Strangely enough, my resized frame was a tight fit match for the tab. That was just a serendipitous occurrence.

I measured the tab and slot, and made a quick 3-line svg to cut the slot bigger. Placed the frame right under the lid camera and eyeballed the placement. The cut was perfect and you can see the cut-out here with the tab properly fit.

Oh Snap! The BBB is a decent material; but the living hinge on the larger prototype snapped when I opened it. This is where you either have enough material for flaws or you pay for the proofgrade, depending on your preferences, resources, and tolerances.

No real finished product yet with these experiments. I’ll cut a proofgrade frame for Fathers day.

The kids have really enjoyed the simple puzzles. For example, one Googled image, with my son’s name added in Gimp, add the GF-included puzzle file, and here’s the result:

im sure you figured out why the hinge broke on the larger one…thats one part you cant resize…

im sure you figured out why the hinge broke on the larger one…thats one part you cant resize…

here in Utah!!

here in Utah!!