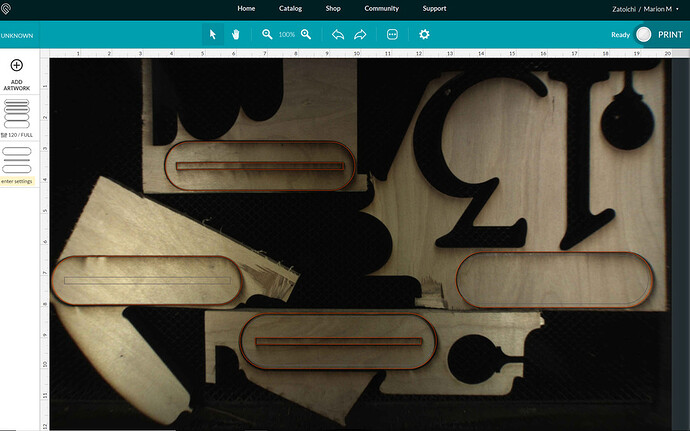

You know the feeling. You find that perfect piece of scrap and you get the alignment perfect…

Let’s see your pics!

The few that were perfect there was no leftovers.

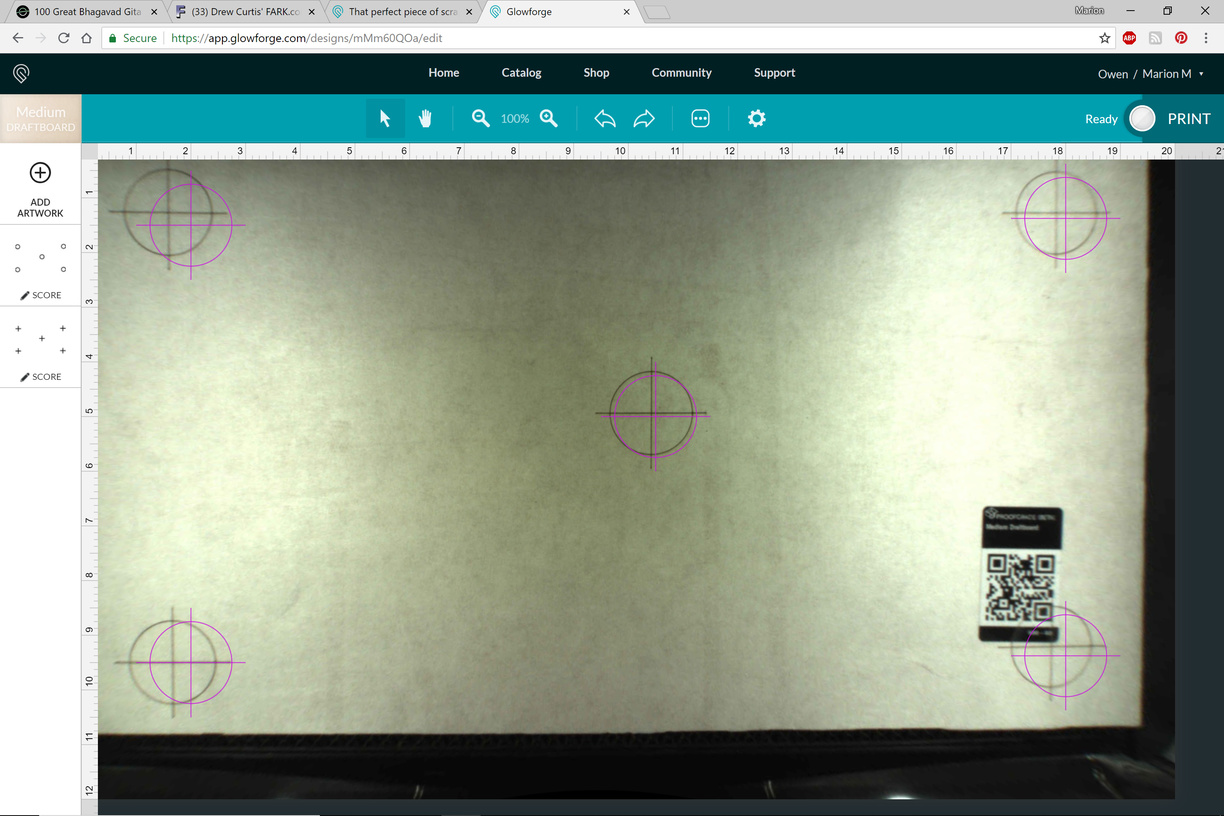

Well, you ARE using bed rulers, which makes all the difference!

Yep! BTDT!

Its wonderful!

I printed and applied my bed rulers, but never use them. I was always confused how to use them, but I thought that they looked handy. Since the crumb tray can slide in the dimples, I assumed that I couldn’t trust the rulers to be a solid reference. Do you mark you GF bed under the tray and align the tray to the bed marks?

I use the really odd/small scraps to make more bed pins - mine seem to disappear like socks in a dryer ![]()

I find the bed pins to be ablative. Where the design does not come too close and chews off a bit the honeycomb eats after some number of uses and if the material is not too thin to hold it is often too thick and has to be whittled down to fit the hole. like socks that show up eventually there are few places around where I am working that I cannot find a few, and of course there are always some when I empty the vacuum cleaner. ![]()

The leftmost, white ruler is permanently fixed on the crumb tray. That was possible because the tray sits in the dimples and is held in place when you close the front door. To find where to put it,

I just lasered something at the top left most spot, then attached the ruler to the crum tray to match the cut before removing anything.

The other ruler is a simple piece of scrap that can be removed. It’s width is that which can never be lasered. So, again, that same simple cut of the top and left most lines you can score in the app tells you how wide to make this piece.

Mind you that the leftmost edge then may get thicker depending on speed and type of operation being done, but that’s a whole other discussion.

Maybe a video would be better… sorry if this is confusing

My crumb tray can still shift with the door shut. I have the Pro with the slot guards removed. I could always snug it to the door as a practice.

I see that the brown ruler is a spacer for the dead space that can’t be cut/engraved.

Thanks. Good guidance.

I do that most times except when running a full sheet of PG in there. For repititious stuff I’ve marked the limits of cutability with tape and I align a left & top spacer. The top one is held in with pins & magnets. That way I can slide a piece of material in there and the corner is just barely cutable. Maximizes my material use.

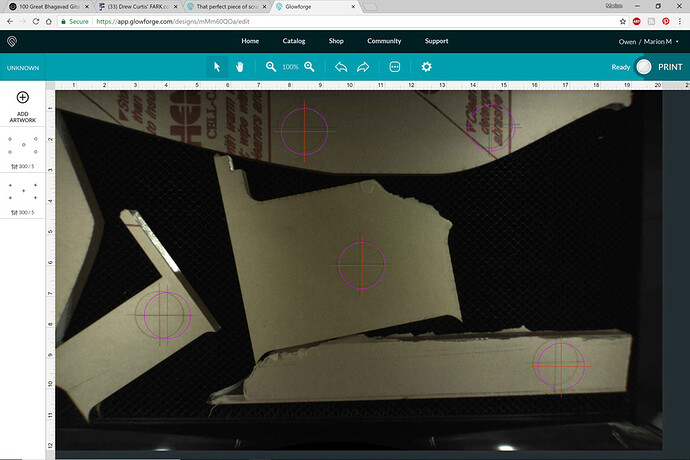

Not to rub it in for those still struggling with alignment by camera:

Hoping that Zatoichi’s replacement is as accurate.

Sorry, but I’m afraid that does rub it in.

Well, now it is a different story. The new machine is a bit different. I’ll need to double check crumb tray and a few other things. Make sure it’s level, etc. but it is placed in the same spot as the last one.

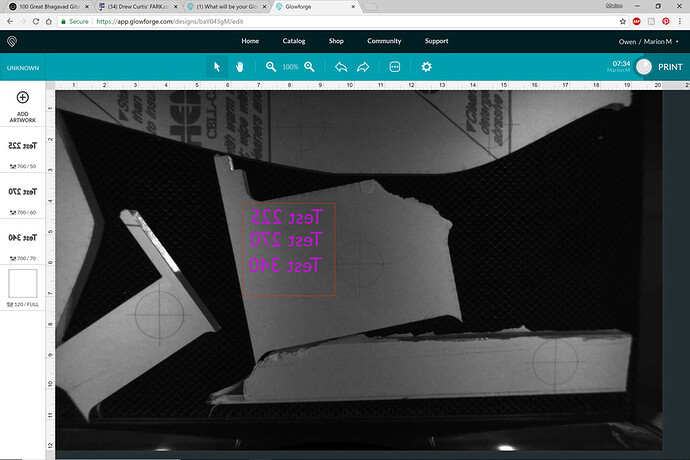

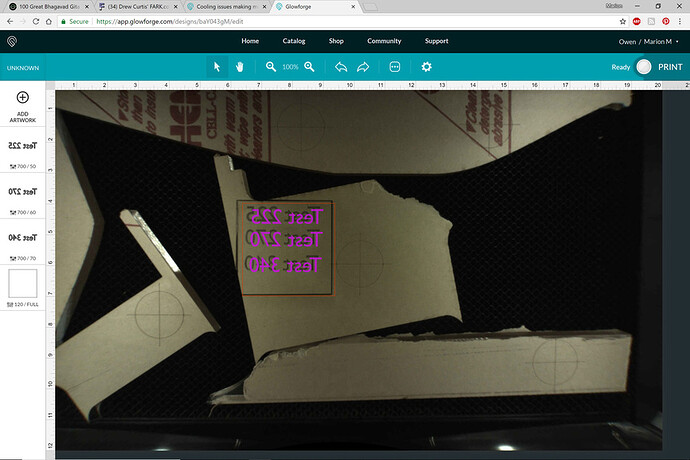

And on the scraps aligning each individually:

And finally this which is slightly off to the left of the center of the lid camera. Will definitely have to do some troubleshooting here, or just work with it.

This is all on consistent thick acrylic.

Sorry to see that’s how your new alignment turned out. I am still waiting for a working replacement, since August 1.

My alignment is sometimes within parameters and occasionally NOT. I really want to use the pass-through but don’t want to waste material. The one time I did try it, using cardboard, I couldn’t figure out how to get it aligned properly. Frustrating as I would love to do larger jobs.

I’ve been wondering about accuracy of alignment on the passthrough, that’s too bad, I can only imagine the frustration with that much material.

Oops.

Awesome ideas!

The automatic passthru capabilities are not yet S/W enabled. I have my own ideas how they can do it with precision but speculation is just that. Yes, I know, the S/W improvements have been glacial. But I trust that the current manual methods are temporary workarounds. Not going to waste material either.