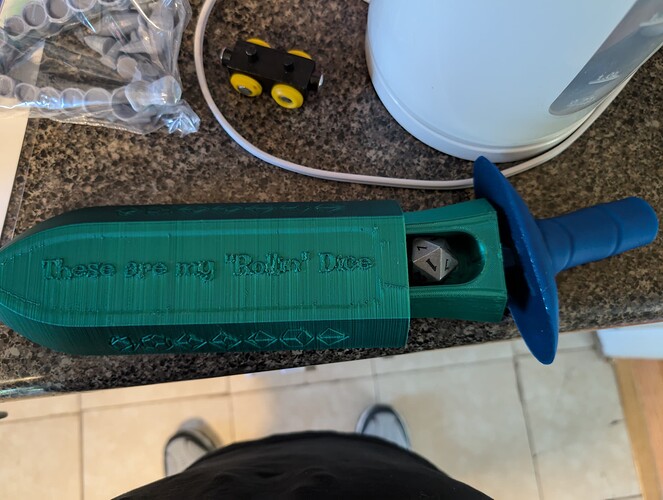

Almost a year ago I started 3D printing with PLA, one of the things I started trying to make is a dice hold for a long time friend and D&D player. Since I had started making this, his rolls at the Game table were…very one sided, with a very high amount of nat 1’s on both digital AND physical dice. So when this project kept failing at every… single… turn… I leaned into the failure, hoping each one would fail to add to the mess. I took a spin down counter from MTG and sanded off every side and made a 20 sided die of nat 1: 19 nat ones and 1 nat 2, because the die failed so badly it couldn’t even get nat 1’s right!. Today is finally got to give it to Him and it was priceless, we had a great laugh and then I gave him his Resin dragon tooth dice.

List of failures:

Handle stopped printing half way through, never finished the pammel but not actual reason for the failure.

The form fitting connector only is form fitting on one side

The “Blade” also wasn’t form fitting as it was supposed to be able to fit the sheath, it instead got stuck half way in, the skirt on the back refused to peel off, and it left the decorative pattern on the back a royal mess.

The sheathing was supposed to have decent lettering but instead it did a raised 3D lettering instead of an ingressed lettering and the supports refused to remove.

All in all the best failure I have made ![]()