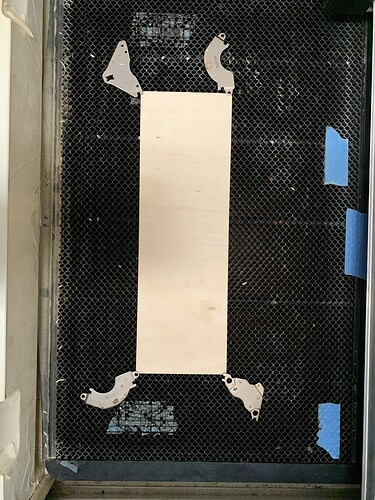

Since magnets are a no no in the machine, could you use flat steel bar stock to hold material flat? I saw some of this 1" wide by 1/4" thick bar stock at my local Menards. Since it’s only 1/4" high, it shouldn’t hit the laser head.

This stuff is quite heavy as well. Of course if the board is really warped, hold down pins will work also.

I don’t see why not…

I generally find pins easy to use, but this could be a nice solution in some cases.

Let us know how it works. I still use Magnets as long as they are on the front third of of bed. Any farther back, and it may interfere with the air assist fan. I use a combination of pins and magnets, but like your idea as well.

I have found a flat hold-down is good for pinning the top edge of paper or cardstock to be engraved, it prevents the air assist from blowing under it.

i’m sure it will work for things that are thin to hold them down flat. but if it’s a piece of plywood, it probably isn’t enough.

i still use magnets, but only salvaged hard drive magnets that have the thick metal plates on one side that dissipates the magnetism on that side. i can literally flip them upside down with the plate on the honeycomb and there’s zero stick. but flip them magnet side down and they’re super strong. additional bonus that the magnets can sit closer to the honeycomb and have the very edge of the top plate on the wood to hold even stronger.

YMMV, but this has worked consistently well for me. I had one or two issues with rare earth magnets, but zero since I went exclusively with salvaged HDD magnets.

Yes, I use scrap pieces of metal to hold things down and sometimes I’ll use magnets under the ends of the bar to really secure it to the tray if need be. (I place the magnets well out of the way of the head.)

I actually am brand new at this, but I don’t want to screw up the machine either. I haven’t tried it, but the bar stock is only $6 so it’s a cheap experiment!

I still intend to use the hold down pins as well.

Me too… works great. I added a little rubber handle on each one that makes it easier to lift from the bed.

I have found that when the magnet is difficult to pull off of the crumb tray, sliding it onto the plastic frame around the tray will break the hold and make it easy to remove.

“Flux Plates/Ring”. And yes, their purpose is to redirect the magnetic flux from the back side of the magnet. Done correctly, most of the field is contained in the piece of metal and there is very little stray magnetism. It’s critical for an HDD because the media is also magnetic, and HDDs often get stacked close together in server racks. You can’t have stray flux from one drive erasing data on an adjacent drive. That’d be bad.

There’s a Nickel-Iron alloy called “MuMetal” that actually blocks magnetism.

I used to make HDDs. Switched to SSDs, though.

i use one the little picks i got in this kit if it’s hard to pull off. the right angle one poked through a hole in the end of the plate and you can pluck it right off.

I use a pair of “bars” made of scrap strips of wood to hold down paper in the forge. for plywood, the pins work for me.

Great idea! I have a ton of them. I’ll give the a try

Another great idea!

This topic was automatically closed 32 days after the last reply. New replies are no longer allowed.