What is the thickest wood or polyethlene you can cut all the way through?

What kind of machine do you have? (The Pro can make it all the way through almost 1/2" thick with multiple passes, but there is a lot of char and kerf damage.)

For an official answer, I suggest the Glowforge product page: https://glowforge.com/faq/materials-and-uses#what-is-the-thickest-material-that-glowforge-can-cut

I have the the middle machine

That should have enough power then. Multiple passes - you can probably get up to about 0.47" or so, which is nominal for half inch.

But it is going to be an extremely messy, flamey process and you’ll need to watch it like a hawk.

Why do you want to cut something that thick? It would be extremely heavy. (Oh and don’t try to cut poly that is that thick…you’ll start a fire.)

I’ve cut 1/2 inch western red cedar but I don’t remember the settings I used.

If these would be for outline cuts, and if you have (or have access to) a scroll saw, bandsaw, or jigsaw, it might be easier/cleaner to score or do a partial (guide) cut on your laser, then use the saw for the actual through-cuts.

Alternately, your Glowforge is great for making router templates.

I managed a full inch thick acrylic - but it took something like 12 passes and the kerf was wiiiiiidddddeeee (worked perfectly for my purposes, but I wouldn’t do it except for a one-off).

The machine is designed to cut up to 1/4" thick so anything beyond that is wish fulfillment

I’ll add that it depends massively on your specific material, that you have on-hand, right now.

My 3-yr-old Pro is still functioning perfectly, cuts all PG materials just fine. I bought some 1/4" MDF at THD yesterday, and it can’t cut through it on the slowest speed (100) and full power. The 1/4" MDF I bought there three years ago is cutting fine (I have scraps from an old CNC router project), using PG “Thick” draftboard settings (132/FULL) which cuts significantly faster. The material is exactly the same thickness.

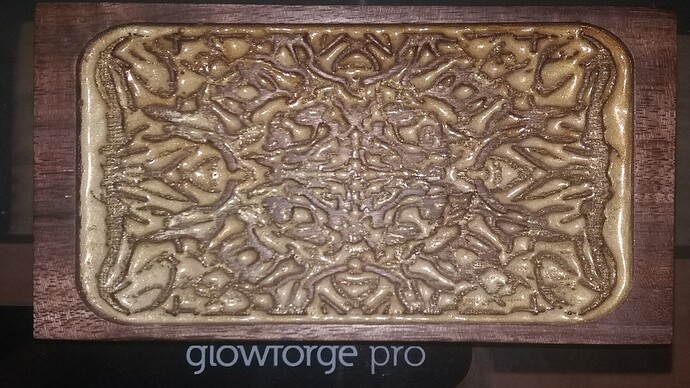

I have been cutting 0.46 and 0.547 walnut just fine. A height just over 0.5 will cut but the focus will not go over 0.5 so it made mess even though checking the fan dropdown did barely pass without hitting.

The harder woods like maple, walnut, cherry, will manage but softer(or more flammable)woods may burn up for trying. I had what I thought was walnut but it started to burn up when I tried to engrave it. Zebrawood is very hard but more flammable than most.

this was 0.46.

I’ve cut through 1/2" basswood and cherry hardwood in 2 passes and 3 passes, respectively. Have to sand off the black sides.

Thanks for the good idea. I have a scrollsaw–I’ll do this with some luscious thicker wood I saw at ReStore yesterday. Could not figure out how I’d laser it other than for surface texture.

This topic was automatically closed 32 days after the last reply. New replies are no longer allowed.