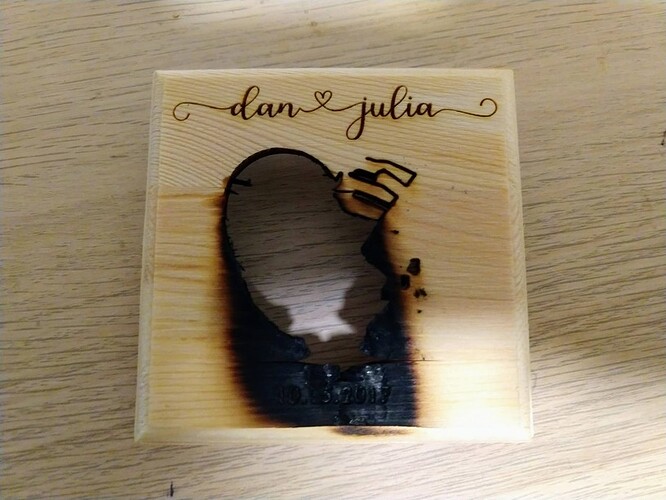

is this the reason most glowforge fires start?

Never had a fire but seems to me the most common fire post comes from very detailed (cut lines close together) cutting on acrylic.

Maybe not most, but definitely some.

The adhesive on masking is pressure-sensitive, so burnish that stuff down good so it stays in place.

I agree, I think most fires are people using ill-advised designs and settings.

Of course the last thing a person who has a fire wants to hear is “well that’s on you”, but here we are.

A camera inside the unit? I mean, that COULD cause a fire…

A camera inside the unit? I mean, that COULD cause a fire…

well, maybe a fire sale!

I don’t recommend engraving on matches either… really touchy

or engraving gas cans! – fumes, your know.

Now I’ll have to figure out how to get one in there to test.

Seriously though, you would be amazed at some of the things people will throw under a beam to see if it will cut or engrave. I was talking to some one of Facebook a year or so ago that was trying to cut styrofoam pieces for an R/C plane. They were complaining that the GF was worthless because it should be so easy to do. I tried to explain to them that styrofoam and many other plastics are nothing more than a solid form of napalm.

OUCH  that left a mark…

that left a mark…

When I do my layout in AI, I look for areas where I have many closely spaced cuts, and I break those in to separate layers/colors so when I import to GFUI, there aren’t any adjacent passes.

Think of an array of vertical lines with very small spacing between them. I do two layers, with each layer having every other line like this:

Original:

|-|-|-|-|-|-|-|-|-| = one layer

What goes to the printer:

|–|–|–|–|–|–| = layer 1

–|–|–|–|–|–|–| = layer 2

I had to do this when I started cutting Delrin. The multiple adjacent cuts would melt and deform the plastic. Too much heat in one area. Separating and interleaving the passes fixed the problem.

Hmm. The Forum seems to be stripping out extra space characters. So imagine the “-” are actually blank space…

When I was young we used to make napalm using styrofoam and gasoline (or white gas, whichever was handy). Dissolving the styrofoam in it would thicken it up and then it would stick to things like real napalm. ![]()

Been there, done that

Then I got into the “boom” factor.

If you’re like me you learned to do that dangerous stuff without benefit of the Internet ![]()

High school chemistry class!

Most of the fires I see are definitely due to masking, usually on acrylic.

I got the teacher to help me grind up some Iodine and use it to super cool some ammonia ![]() and then we washed in water and while setting it to dry I accidentally spilled it all over the floor. A bit later someone walked in to get something and there was a loud bang and a purple haze rose from the floor.

and then we washed in water and while setting it to dry I accidentally spilled it all over the floor. A bit later someone walked in to get something and there was a loud bang and a purple haze rose from the floor.

If I remember right, (and I probably don’t as that was 50 years ago) a little silver nitrate and calcium carbide added to it made a compound that when detonated, created a very loud report with very little flash. We would pass it through filters, let it dry and then leave the little filters in the hallway of the science building for the students to walk on between classes. It was super unstable and looking at it wrong tended to leave our ears ringing. It’s a wonder I survived chemistry class.