No affiliation or direct experience, just passing on the info.

Forgive me, but what purpose does this serve?

Who takes pics of their tools?

Aha, my bad. I don’t click on random sites that have a low trust rating.

My organization is well established. It’s called “rummage”…

You don’t trust me by now?

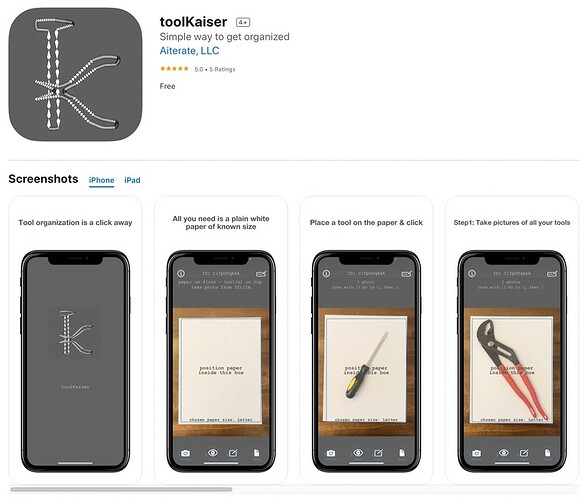

Cool concept!

No offense intended. I’ve worked in IT security since the 90’s, and am a tad cautious.

having made tool inserts for many drawers, this looks like a huge time saver. I’ll definitely give it a try!

Ahh I wish my space looked like this!

I need one to put them away for me! ![]()

When I worked on aircraft we were required to have tools in drawer inserts. It made sure you weren’t dumb enough to accidentally leave a tool in an engine or cockpit. But those days are long gone. I don’t organize my tools beyond putting like types together.

That said, I really could have used the program to make foam inserts for my telescope parts and eyepieces. It was a pain to do it trial and error. A single glass eyepiece might be $500 and definitely needs cushioning for transport. In addition, nothing ruins your day like finding out you left an expensive part on a rural mountain top the night before while observing. Usually carry a dozen or so eyepieces that are constantly coming in and out of my pelican style cases and coat pockets during the night. A quick look at the end of the night assures me that I haven’t laid one down somewhere.

If anyone tries this I’d be interested to know what you thought of the program.

They really bury the lede. It was a lot of work to figure out what the point of all this was, I had to watch a video and skip to very nearly the end before I could see a piece of foam being laser cut.

Yes, every piece. You could inventory your box at a glance. On top of that, each piece was engraved with the squadron and toolbox number. When the pilot went inverted and he could pick a socket off of the canopy he knew exactly who to have a “conversation” with.

If a screw, part, or tool was dropped in the cockpit, that bird was down until it was recovered.

When I was setting up my own box 40 years ago I started with that system;

But over the years that has devolved into the “rummage” layered method as evidenced in the previous picture, since a $60,000,000 aircraft or someone’s life isn’t at risk. Live long enough, and it looks like @geek2nurse’s father’s garage - where he was the only one who could find anything in there.

Sadly this is one of those videos that if you have the sound on it’s almost the first thing they say, but I almost never have the sound on!

They need a marketing manager.

Here are some of the inserts I made the hard way (manual tracing). After years of digging through drawers looking for tools, (only to find it wasn’t in the drawer after all… I left it out somewhere in the shop) It is a game changer having organized drawers.

They have an interesting approach. I believe you can save work in the “cloud”. I suppose you could have a layout with your tools, and after some time you bought more you could load the original and add the new tools to the layout.

This topic was automatically closed 32 days after the last reply. New replies are no longer allowed.