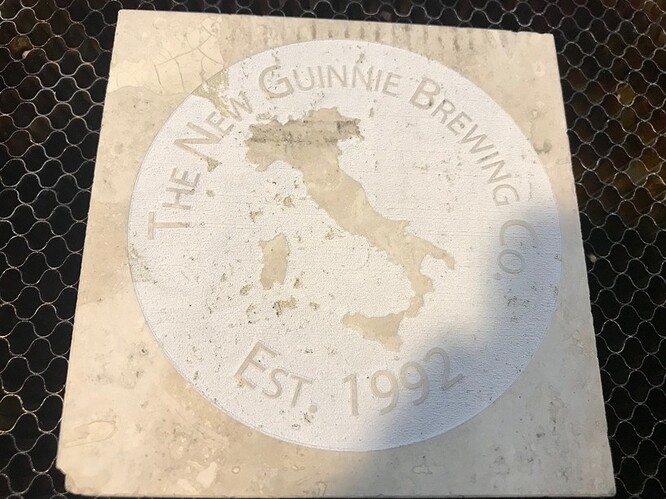

So now that I am furiously making travertine stuff, figured my colleague’s brewery needed a custom coaster. So I reverse engraved the brewery logo into one of the Home Depot tiles. There is an interesting side effect. This was a full speed/power 450lpi 3-pass engrave and the tile got pretty hot after 90 minutes. Interestingly I noted cracking in the corner of the surface I assume from the heat.

Is this with your new machine?

Travertine is by nature a stone with some voids in it, and they are normally filled with a mixture of cut dust from the stone mixed with I don’t know what, I presume a cement type mixture.

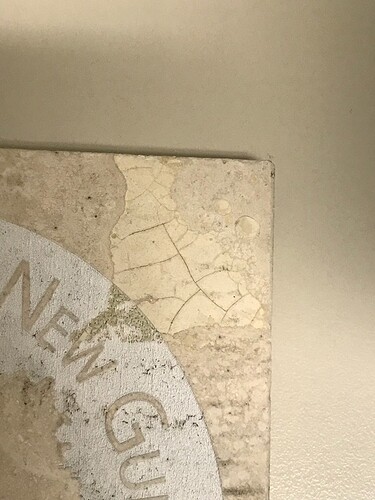

The cracking seems to be restricted to what looks like one of those fills to me.

Just a guess, but I suspect a thermal expansion differential between the materials. Too bad.

Congratulations on your forever machine Doctor!

No, just my PRU (the new machine is in the box)

the cracked part does look like fill, but could also be an organic binder in the fill, In any case on a long engrave like that on stone, I would be worried about cracking unless the stone was especially strong and chemically stable. I watched a friend try to size a ring with a beautiful Amethyst that was exceptionally dark and when he was finished he had a beautiful clear quartz stone, so there can be many things that affect stone.

BTW many sorts of Glass particularly reds can do the same thing

What a rocking effect - thanks for sharing!

It is a cool effect though! Really goes with the imprint you engraved.