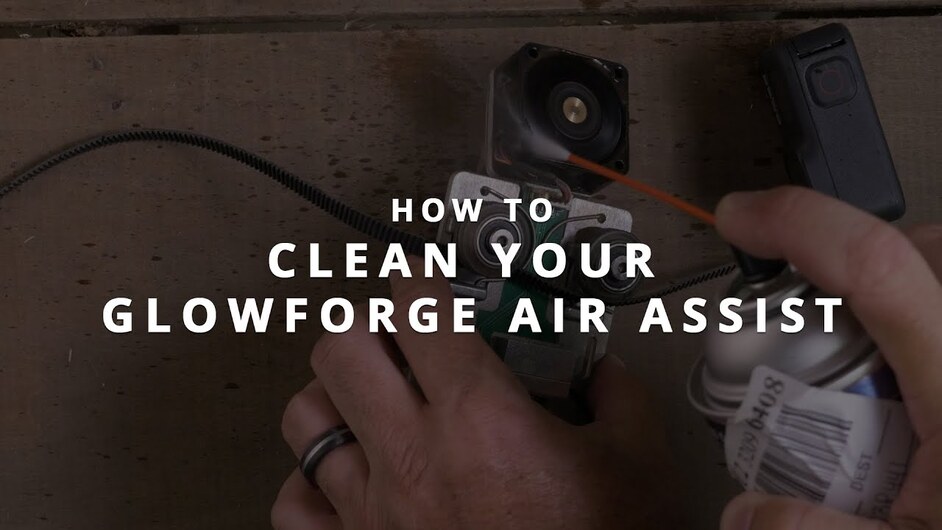

Here is a very quick walkthrough on how to clean the air assist. Videos like this already exist. The purpose of this one is to give a few better angles of the hard-to-see areas.

Cool! Shifted it to the Tutorials section for you!

On all the machines I’ve had I have never had to adjust the tension on the pulley head.

The drive cable will come off easily, but getting it back on again is sometimes easy, sometimes more fiddly.

Just saying because some people will prefer not to undo the tension each time.

Also, the various liquid cleaners are OK if the fan is not too mucky, but as a bulk cutter of MDF/Draftboard I’ve found that fan gets very gunky and actually needs a good scrape out.

The scoop where the air gets blown out also gets clogged up to and you might need to unscrew that plate (with the same hex key) to get what is clogged up underneath.

I no longer use any of the liquid/spray cleaners - I think they to tend to make the fan sticky and are not very good at cleaning.

All that said, I think a lot depends on what you are actually cutting and how often you clean that head as to what works best for cleaning - I’m glad there are many ways - because sooner or later we are all going to have to try something different.

See this about how to clean the scoop

Thank you.

Very nice tutorial . I have never cleaned my air assist fan but will check it out now.

I loosen the 3mm also. It can be rolled back on the pulley but I elect not to stress the belt. Probably doesn’t matter, I just find it easier. I do find it necessary to tension the pulley with my thumb on one hand and use the other to wrench.

Very nice. I attach a shopvac to the exit of the shroud and turn on the shopvac. This pulls air through the fan and the shroud fast enough to spin up the fan. I then use Purell hand sanitizer and dump it in the fan. As the fan is spinning much of the dirt is spun off by centrifugal force and then pulled through the shopvac so none of it gets anywhere else and it cleans the shroud also. I do this with the Glowforge off and not having to remove the carriage at all.

I let the vac run another half hour so everything is completely dry

How often do y’all do this? I have never done mine, because I’m terrified of breaking something trying to get it off and then back on. I did spray some canned air through it once.

I suppose it all depends on how often you use your GF and the type of materials you use. I’ll let others speak who clean the fan with more regularity.

I don’t think you’ll break anything unless a part is somehow already about to give (probably unlikely…mine is one of the preorders and everything still feels fine). It really is easy.

I did it a lot more before I figured out about what the magnets were doing. less call for it now but then I don’t cut MDF either.

I cut a lot of mdf and get tons of crud caked everywhere so I do it about every two weeks.

So, I’m guessing proofgrade walnut counts as mdf since it has the mdf core? Yikes, I suppose I should look into this then (as it happens, the rest of my 'forge needs a cleaning as I can no longer see the inside of the laser tube-- I know it’s not required to clean that, but that’s how I judge when I need to make sure everything else is clean).

![]()

![]()

![]() Me too… or when I can no longer see the bed unless the lid is open.

Me too… or when I can no longer see the bed unless the lid is open.

This topic was automatically closed 32 days after the last reply. New replies are no longer allowed.