Currently having to hunt down that spreadsheet so I can figure out what the old settings were that worked that im going to have to translate to every time now. Seriously a pain

Happy Cake Day Dan!

I totally get it now. GF went with an arbitrary scale like we’re all used to seeing on audio equipment: 0-10… but 10 “what”? Doesn’t matter, see. 11 is that much louder.

The Glowforge starts at 10, but if it started at 11, it would be that much more awesome. However, it goes all the way up to 1,000. That’s pretty wicked.

I wanted to call it arbs (arbitraries) per pew.

That’s what I am trying to figure out. What is the problem this is supposed to solve? That it doesn’t refer to units IRL, bypasses the metric/imperial issue. That it allows for much finer resolution in speed.

It’s just a strange thing to see this all of a sudden and be such a departure from what we have all experienced thus far. And it certainly is a departure from what the forum discussions about speed have tended to focus on. While we couldn’t come to a consensus about what the units should refer to and be based on, that it needed to have some actual frame of reference was important to everyone with previous laser experience.

I understand the arguments, but as a newb I’m in no position to debate. The team devoted a lot of time and energy in development of this system, and I can only assume there is a logical reason that is not apparent to me.

I wouldn’t even be in the laser arena if it weren’t for this company, so I’m just happy to be here.

Actually, you’re the perfect type to weigh in on this. I think all experienced laser users prefer actual units of something that’s “standard”. Part of that is no doubt comfort with the way we’re used to doing things. But it’s possible that we’re not open to seeing why this is better. I adjusted to in/min vs mm/sec that I’m used to using. Would have preferred the mm/sec but no big deal. How fast is 10? How about 1000? Is 1000 a hundred times faster than 10? (No…but why and what does 10 or 1000 mean?)

You on the other hand are the target market and because you’re not wedded to something else, you can tell us if this makes it easier for you to understand and use the laser. Also you can weigh in in whether you are better off not being able to relate to settings other non-GF lasers use - maybe those just confuse things.

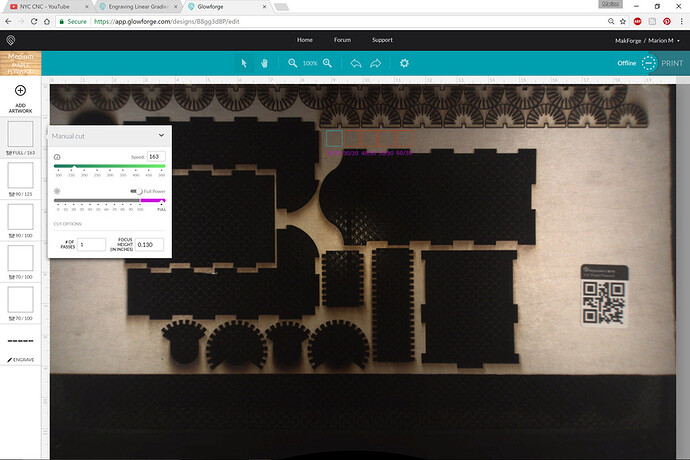

One of the things about the new interface confused me and I had to reorient. The order of settings for manual cut is speed first on top and then power. So I set them. Then I look at the column of settings and I had to double check everything because power shows first of the two numbers even though you set speed first. This is confusing.

As another laser newbie, my take on this is:

Things need to make sense. Numbers with no units make no sense.

Also, as others have pointed out, I’m going to sound like a moron or “one of those silly Glowforge people” talking with other laser owners at Maker Faire. Who wants that?

Well I actually get why they’re doing it, especially if they painted themselves into a bit of a corner by early GUI development being based on only one unit of measure - either Imperial or metric.

If you want to (accurately) convert between other multiple units given the limitation of the hardware, you have to break everything down to the lowest common unit. I wouldn’t be surprised if the mask is revealed that “TPY” is actually the number of stepper-motor steps needed to travel an inch in a second(*). At 0.001", that’s the lowest whole integer number you can specify for a unit of distance… so that becomes the new unit of distance. From there on, it’s just conversion to different units.

But the problem is this is all speculation, because the new “1000 TPY” doesn’t indicate { distance / time } in any relatable manner to anything.

(*) I’m grasping at seconds here, because without any actual units, it’s probably 1000 steps to move one inch, which is a distance measure – not a speed measure.

Well, from this perspective of having been exposed to the other settings and learning what little I have, naturally I would prefer being tethered to that world that I could reference against known values, but again - I have no idea what the company’s motivation was, and I’m in no position to criticize.

I do recognize that my learning curve just got reset.

This is great feedback for @Tony and team - I don’t know if it was intentional. Can you file a support ticket?

I wish there were a way to choose units. Just let us pick, it is only a few days of coding.

The in/sec makes intuitive sense to me, but the arbitrary numbers become normal as I use them.

I doubt I will be spending much time talking to non-glowforgers about the gory details of my settings, and I don’t much care what they think of me (or of Glowforge).

That said, if votes are being counted, mine goes to real world units every time.

Another vote for real world units.

I would be very interested to hear the logic behind these new scales. I hate to think it’s simply “1000 sounds really high-techy, ya know” driving this change. I also hope it doesn’t boil down to “this’ll make it harder for people to leave the Glowforge ecosystem”. The more manipulative the reasoning, the worse.

From what I’ve heard, I would also like to put in a vote to switch back to “real” units.

I’d be more on-board with this change if it was clever or actually offered a tangible improvement over using the measurement systems we already have. For instance, if the APU (arbitrary power unit) and the ASU (arbitrary speed unit) could be multiplied together to get a “power delivery” score, that would actually be pretty cool.

Like, if I was happy with a cut done at 50 APU and 300 ASU (delivery score: 1500) it would be cool to be able to assume changing the power to 75 APU and the speed to 200 ASU (which would have the same score of 1500) would yield a similar result. Of course, for that to work, either the ASU or APU scale would have to run in reverse so that smaller values would denote more speed or more power.

you’re right, this part is a nice idea, but i’m skeptical it would work as you hope; there’s no guarantee that a substrate will respond the same way even if it would appear that the math works out (i grant that it may not be that different for some things).

You need to divide power by speed and multiply by passes to get the energy density applied to the material. I think that is as close as you get to knowing the effect it has. It won’t be linear but I don’t think you can have any arbitrary scale that makes it linear because each material behaves differently. The physics of ablating acrylic and ablating wood are very different.

The new speed scale cant be used this way because of the huge offset at the bottom end. This is assuming 40 times the energy density doesn’t have 5 times the effect.

So why not get rid speed and power all together and give a pew pew score or something at with a bias to as fast as possible but still get the pew pew. That would make more sense then speed 1000 . It would still put gf users in the blind with the female community but would have the goal of simplifying things. For this material I need 485 pew pew. And for this one I need 1900 pew pew … O but single pass is only max of 1300 pew pew so then it would automatically pick double pass at 650 pew pew

Do my rambles make sense ?

Please don’t give them any ideas. If they want to label it as delivered power fine, but never at the expense of giving us control over speed and power. Rarely use the automatic settings as it is because they can be too limiting. (For the record, anything that had a setting labeled Pew-Pew would not be allowed in my home.)

No it is an over simplification. You can cut through a material with high power quickly, lower power more slowly, or with multiple passes. These are all delivering the same a mount of pew pew in total and cut to the same depth but will give different amounts of char / meltiness, splash back and corner over burn. Some of us want to be able to optimise these things and not have only a single variable to control.