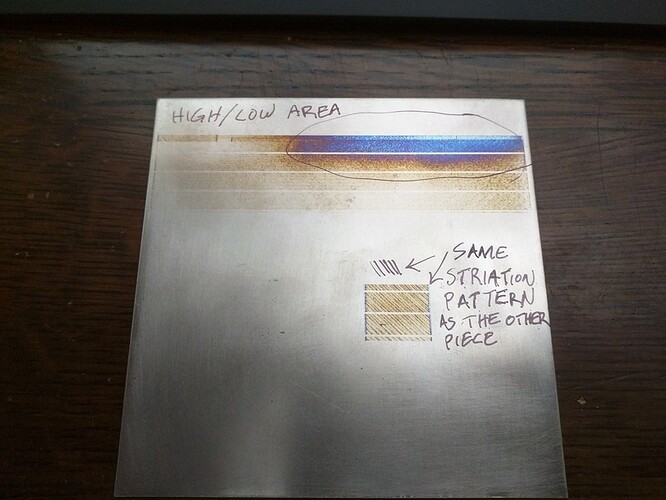

Could it be that the surface is “more heated” aka hotter in the center than the edges. That is, it was heated from the one side before marked then heated again as the side next to it was marked. Where as the side only were heated more after being marked or before being marked (left then right)?

So we don’t have a rainbow of colors like I hoped, but I bet we could make a pretty cool beach scene with this.

Not likely. The color bands indicate that they reached a higher temperature than the centers. In other words, the colors in the bands are the colors you see “higher” up in the array.

Check out the 10th rectangle (column 2, row 3) in the 168 array. The bands are blue and the bulk of the rectangle is tan. Blue it the color that seems to appear when the titanium is lased with a high(er) power beam.

Here’s a great video discussing the relationship between color and temperature…

I highly recommend that channel to anyone interested in metalworking.

I am very curious about repeat exposure… would you be up for re-running a few of these tests orthagonally? Should be able to get 3 or 4 power levels across each previous run and retain visually distinct segments.

I think I can do that. The foil squares came in today, so my goal will be to whip out at least one good test by the end of today.

edit…

Welp, I gave it a shot, but it seems that titanium is very sensitive to focal distance. At least, this is my working theory based on the result of my latest marking “test”.

Unfortunately, the first piece of titanium I tried was not flat. It seems to have a uniform thickness (~0.53mm) but it’s a little bent/warped. I may have bent it while sanding/cleaning it; I won’t bother cleaning the next one.

I can’t think of a way that I can flatten it with the tools/knowledge that I have. I’ll check out the other pieces and see if they look better. If not, I’ll just do another test on the piece that I have been using.

another edit…

I’ve messed around with it for several hours now. Foil may be a no-go. At least pieces this small/thin with this much coverage attempted.

I took this same piece of titanium and flipped it over and super-glued it to a granite surface plate (with a piece of masking paper in-between). It was pretty flat and pretty perpendicular to the laser (± 0.2mm at every spot I measured with an indicator attached to the head). The first strip of engraving was fairly uniform, but it was brown. I canceled that engrave and restarted a couple of times after messing with settings, none of them seemed to be working very well so I basically gave up. When I pulled the piece of granite and foil off the bed I noticed that it had curled up a couple millimeters in the area that was marked. Argh.

I decided to give cutting titanium one more try. Turns out that was my last try, at least for a while.

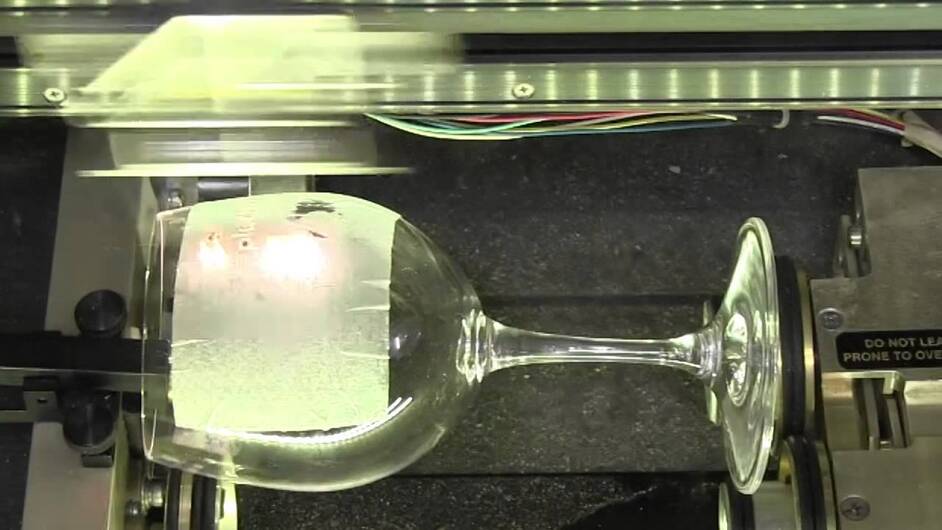

The foil started warping almost immediately. I decided to ignore it and just see what happens. After a while it started to look like it might be breaking through on the left side. The little explosion of light at the point where the laser connects with the metal started to sputter. It looked like there might have been a couple small pinholes where the laser was passing through the metal so the little ball of light/fire/plasma/whatever wasn’t being formed any more. As I let it continue, the area where the sputtering happened seemed to get longer and longer, as if the pinholes got stretched into short lines. Then a small area on the bottom right started sputtering! More evidence that it was breaking through, slowly but surely.

After a few more passes the ball of light disappeared almost completely. The odd thing was, I could see the red laser spot on the titanium. Hmmm… that’s odd. I was doing this to experiment though so I let it continue. Then, a couple seconds later, I noticed an anomaly on the lid. What is that? Oh crap, it’s melting! Oh no, it’s starting in a different spot! Quick, open the lid (an odd thing to do, but it’s as close to an “e-stop” as the machine seems to have.

Well darn, not only did it not cut through the “foil”, now I have two spots on the inside of my lid as a constant reminder of when “just seeing what happens” was a bad idea. ![]()

Ouch!

Ouch. Thanks for sharing your findings. I will take this as a firm reminder that one should never leave the laser unattended. If it’s on, I need to be present and attentive.

For the record, Ti in small cross sections will burn in standard atmosphere once ignited. It burns super hot with an intense white light, and is incredibly hard to extinguish. I have had Ti chips start burning from cutting heat when I was making rings on a lathe, and I basically just had to get them out of the chip pan onto a piece of steel plate and wait for them to burn out. Scary stuff!

The elusive Class Delta fire.

“Chuck it overboard” is the best known extinguishing method.

@jkopel, does Ti produce oxygen like burning magnesium or does it need atmospheric oxygen to sustain combustion?

Once ignited it is really hard if not impossible to put out with water, but I am not sure if it will burn under water. Might be a fun experiment to try (with proper safety precautions of course  )

)

Magnesium generates it’s own oxidizer as it reduces. Kill a fire by removing the fuel, temperature or oxygen, you can’t do any of them with mag, really no way to extinguish it.

In Navy fire fighting they showed a training film of an aircraft wheel fire on a carrier. they pitched the entire jet over the side.

The color temperature you describe sounded like a mag fire!

I see from searching around that magnesium and titanium do the thing that aluminum does, namely catalyze the usual extinguishers (water or CO2) to dissociate. (My high school chemistry text said they found that out trying to extinguish aircraft fires.)

But I still wonder about the titanium in this case: was it the titanium fire that was eating the lid, or was it a semi-focused reflection?

I would say column of heat most likely. I don’t know all of the combustion products generated by Ti burning, but I doubt they would be particularly reflective.

A buddy of mine worked for Manley for a while latheing custom Ti pistons and rods. The shavings were fun to play with and yes, are very bright white and hot when burning.

I’m a bit confused. * I * didn’t have a fire, so if you’re talking about my lid I can say that it definitely wasn’t caused by a titanium fire because there wasn’t one. I did use the word “fire”, but that was to refer to the little ball of… something that appears when you lase some materials. It’s quite pronounced when engraving glass.

This video shows what I’m talking about…

That is my guess.

I suppose that’s possible. I did pick up the piece of titanium within seconds of opening the lid and carefully patted the entire surface. Not only was it not hot, it wasn’t even warm.

Again, there was no fire. (The photos I posted are the actual piece that was in the machine at the time. It clearly wasn’t in some kind of inextinguishable fire.)

This part makes it sound like your lid of the laser cutter was melting.

It was. Not from a fire.