Thanks, Henry. How does one attach a file in this forum? If not that, I can put it into a dropbox or some other public storage. What format? .ai, .pdf ???

Hopefully that ill work. Red is cut, black is engrave. 1/8" plywood is just fine. As for LPI, I don’t know, so let’s do medium for now.

Thanks,

Dave

Hmmm. Think I found a way to do this - let’s see if it works. First, in .ai format, then in .pdf.

TestTiles.ai (1.6 MB)

Absolutely. Great experience! Its really good to read that. It is fun!

Fail forward and get better every time.

Dave, because you asked for thoughts here are mine. I would not be worried about the slow speed if in fact it is slow but only will the machine cut the thickness of parts I need. If you are cutting 1" teak then the Glowforge is underpowered. 1/4" and thinner you should be good. If you want to cut 24" x 24" game boards in one piece then the Glowforge is too small.

My take on a business machine is this. You are purchasing the equipment to make money. In order to do this you need reliability and ease of use. You want to make game boards, not mess around with lasers. The Glowforge seems to fit this criteria.

If I rule out the low price Chinese lasers because of this logic. I am left with higher end lasers costing $10,000 to get the 80 watts you mention.

I can buy 3 Glowforges for the same money. The advantages of this are many. You can have all 3 making the same parts for high volume. You can have each one making different parts for flexibility. If one breaks down you still have 2 machines producing.

You have much less financial risk going in. $3,000 versus $10,000. You can buy more lasers as sales volume warrants.

Another key point of my approach is this. Because the machine runs automatically you can be doing other stuff while it is working. It doesn’t matter if it is slow or fast as long as it keeps up with your sales volume.

I did not make most of this up myself. They are all important production tools in the Toyota Production System which is recognized as one of the best in the world.

Anyways, good luck with whatever route you take.

Love your work by the way.

Good point about having multiple machines. The GF is very compact compared to other lasers.

With self replicating 3D printers I simply made enough to keep up with demand for parts.

you and me both, brother

Good points. Thank you. And thank you.

Dave

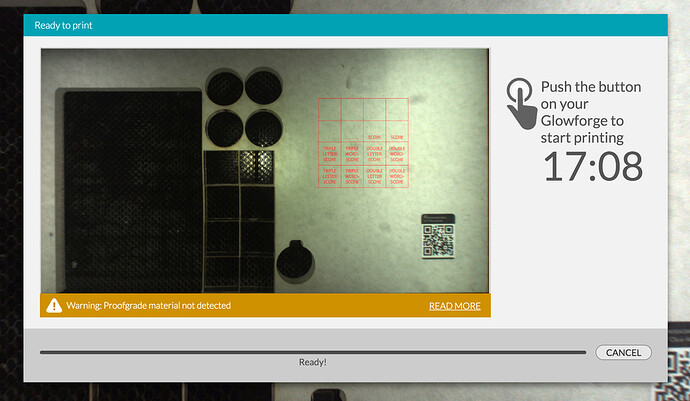

Thanks, I think. Since I don’t have my GF yet, can you tell me what I’m seeing here. It doesn’t look like post-engraving/cutting, maybe a printout of my artwork - and I see something that looks like a time. Is that a GF estimate or actual cutting time?

Do you mind sharing a little about the scenario so I can put into context of my production?

Thanks again.

You have sold me in that if I get into the business of selling/making laserable games, or games with laserable pieces for profit, I’m going to buy more Glowforges.

You are looking at the Preview screen that the Glowforge creates, that shows the exact length of time that a job will take to finish.

So it will take 17 minutes (and 8 seconds) to do your job once you press the Start button.

And it is 100% accurate.

So, if I understand it - it’s 17 minutes for cutting the squares in 1/8" material and engraving the lettering shown to medium LPI? that about it?

Thanks.

Yep. At that size. If it’s larger it’s going to take longer of course, if it’s smaller it takes a lot less. But they do an excellent job of estimating the travel time it takes.

The engrave is the slow part, it cuts them out quite fast, correct?