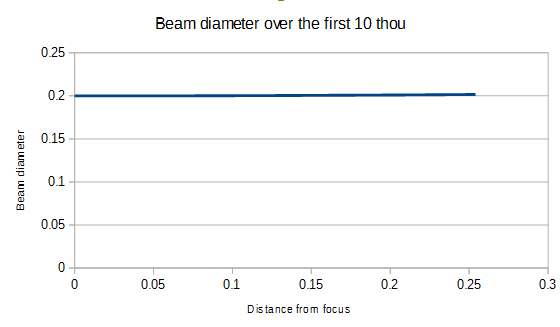

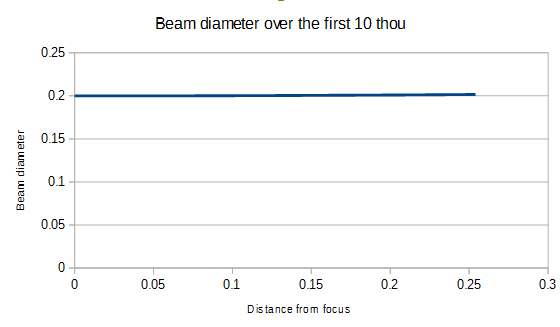

This is what the beam diameter looks like over 10 thou.

Was it misinformation to call it flat?

It is 0.8% bigger at 0.25mm.

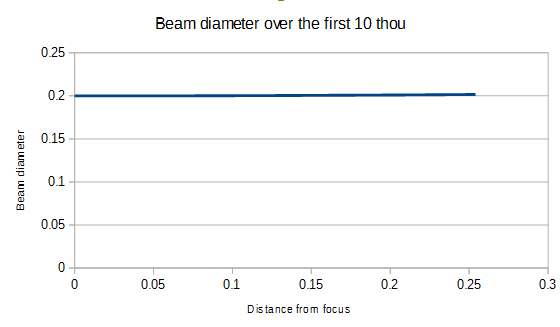

This is what the beam diameter looks like over 10 thou.

Was it misinformation to call it flat?

It is 0.8% bigger at 0.25mm.

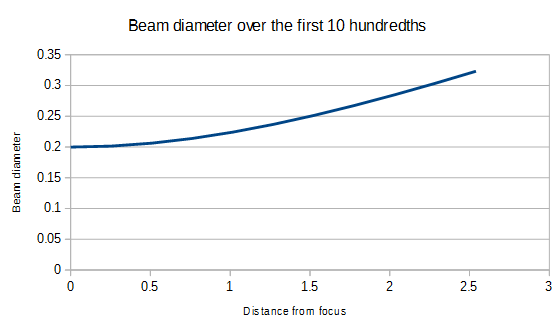

This is how it changes over 10 hundredths.

So my assertion it needs to be a few hundredths out to have any noticeable effect is borne out by the formula.

Got irritated a couple times here. Sorry, accidentally shot myself full of Cordrazine.

You don’t like me. I get it. Move on.

Never argued the assertion (I’ve said that several times) - just the method of berating someone for providing “misinformation” about the effect of thousandths of an inch, but giving yourself a pass on less than technically correct information because it’s “close enough”. Kind of sloppy. But that might also explain why your 3D innovations are in all the cheap 3D printers out there as you’ve mentioned.

That’s what seemed to get even someone’s grandmother’s dander up. ![]()

Gosh…this never ceases to amaze me how people can maneuver around making personal attacks on one another without actually being direct. This thread is like a car accident…don’t want to see it but cannot look away. And on it goes…

You’re right. I should probably step away. It’s not getting anywhere and I expect no attitudes were changed as a result of this thread ![]()

Ha! Tell me about it! I get it.

Yes calling something that looks like this straight

when it actually increases by 0.8% . I should have said “almost straight” or “straight for all practical purposes”, sorry.

Thanks for reaching out. Unfortunately, I don’t have any advice about settings for materials from other sources.

If you are considering printing on materials from another source, you’ll need to determine if the material is laser compatible. This can be tricky: for example, many plastics look alike, and some plywood is made with glue that isn’t laser-compatible. You need to contact the manufacturer, inspect their safety data sheet (SDS), and/or consult an expert to determine if each material is compatible with the CO2 laser inside the Glowforge unit.

I’m going to move this topic to the “Beyond the Manual” section of the community forum. Note however that advice in this section is unsupported and is not reviewed by Glowforge.

If you find that Proofgrade settings aren’t performing consistently on Proofgrade materials, please let me know in a new topic.

I think it is important to call out personal attacks. However, I do not think @Xabbess made one in this case. My understanding of what she was trying to communicate to @palmercr was how his words affected her. How he comes across. The last sentence, “You seem to be a very unhappy person,” expresses the impression she gets from reading his words.

It would have been very different, and your calling her out on it may have been justified, had she said, “You are a sad person.”

From the dictionary:

So the formal meaning is exactly the same. I am unhappy with how GF has turned out but not with life generally. I have been told I am quite flat emotionally as I don’t get very exited either. I was excited when I ordered my GF though.

This answer worries me a lot. As an international glowforge owner I don’t currently have the option to order proofgrade from the glowforge shop. To be told “whatever the glowforge does on third party materials is not our problem” is not exactly what I had in mind.

I know you can’t guarantee safety or success, but I expect consistency. I accept that in this case it is still unclear if the laser or material is inconsistent, but as long as there are possibly laser power variations I would hope for more support.

To address the latter, if the OP ran the same design on Proofgrade material and had issues, he would receive support.

That is exactly what I can’t do in case of problems, if I can’t order proofgrade.

Your initial sample pack comes with an additional piece of draftboard to use for troubleshooting.

I currently don’t have a problem with my glowforge. I’m just worried to be potentially stuck with inconsistent results, and glowforge won’t support me, because it’s not proofgrade.

Yes, without there being a “proof grade art card stock” as an option, there’s not really a “solution” to compare against for the problem I encountered.

Nonetheless, I’ve been busy making gifts before we depart for a vacation for a month, so I do mean to circle back after and try the “spray mount sticky matte” suggestion to see if that works; and probably I’ll buy a different brand of art paper to compare that, too.

Proofgrade is supported because it has been engineered to be very consistent. Non-proofgrade materials may be very consistent or may not be, depending on how they are made. For instance, plywood that is not proofgrade can have internal knots that the laser will not burn through with one pass. This has been shown on several posts.

How do you expect Glowforge to support non-Proofgrade material when they have no control over what it is made of or how it is made? They have nothing to go on. They can’t tell if it is a laser issue or if the material is made with a layer of something that isn’t laserable.

I think that the expectation of support on a non-Proofgrade material is unreasonable. No user should expect to have support if they put in a non-Proofgrade material because Glowforge has had no say in how that material was made. In that case, the user should go back to the manufacturer or seller of the material, not the manufacturer of the laser, as the issue probably lies with the material, not the laser.

This is why Glowforge has provided extra material for testing - If the laser works fine with Proofgrade, the problem is the material, not the laser, and Glowforge cannot provide any support on that material because they have nothing to work with.