I have some 6.4mm (~0.25 in) oak wood.

But I can’t find the right settings to cut it.

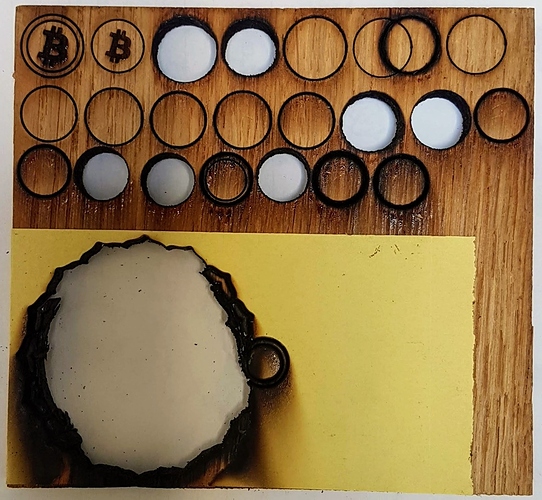

I’ve tried numerous options, but it is not cutting through or it is so badly scorched it is unusable:

Does anybody else have better experience cutting this thick hardwood?

Edit: I have a Basic  and the oak planks are left-overs from a floor renovation. Not sure what kind but very hard.

and the oak planks are left-overs from a floor renovation. Not sure what kind but very hard.

Ran into the same problem with the (almost 1/2 inch) Home Depot wooden floor samples. By the time they were cut through they had charcoal edges.

Surprised at your wood with just the 1/4 thickness though.

Tried flipping and cutting from both sides, but that is problematic without a true coordinate mechanic. Multiple cuts and focus changes did not seem to aide my trials.

Final fix was to size the floor sample with other tools before placing into the glowforge.

So…

Curious if anyone has a solution to this myself.

edit: this comment needed an edit. These floor samples are NOT solid wood, so anything here that works will still fail with them.

Sorry, stopped thinking for a bit…

I used 180 speed, Full Power (Pro) and 2 passes for 6.85mm black walnut. I have some similar thickness red oak, but either I haven’t cut it yet or can’t find my settings. What species of oak? I know oak has some pretty different properties between species. White oak is closed cell and great for boats, whereas red oak is open cell and is more like a sponge. And as we all learned in history class, at least in the US, British canon balls bounce off of live oak.

I had a similar problem with African mahogany, 3 passes finally got through but left it a charred mess. The thing is, I’ve seen it cut by others without the issues I had.

2 Likes

I’ve seen other posts where people speculate that hardwood flooring is treated differently than regular boards. They have reported similar findings: the laser barely touches it, but it cuts this board just fine.

2 Likes

You may want to look into planning them down (to be thinner). That’s what I do with my floor samples from HD.

The piece I worked with is from Lowes and is avg. .265 thickness. The best settings that I found are 800/100 for etching, and 2 passes at 110/100 for cutting. It does have some char on the edges. Using some masking (blue tape) helps with keeping the etching and cuts looking cleaner.

1 Like

and the oak planks are left-overs from a floor renovation. Not sure what kind but very hard.

and the oak planks are left-overs from a floor renovation. Not sure what kind but very hard.