Wow, I never let mine go for that long. You need to get a camera on your printer and check in on that bad boy every now and again. hahahah.

But yeah, I miss the rapid prototyping, but not the headaches that came with 3d printing.

Wow, I never let mine go for that long. You need to get a camera on your printer and check in on that bad boy every now and again. hahahah.

But yeah, I miss the rapid prototyping, but not the headaches that came with 3d printing.

My guy runs a lot of prints overnight, because they’re gigantic.

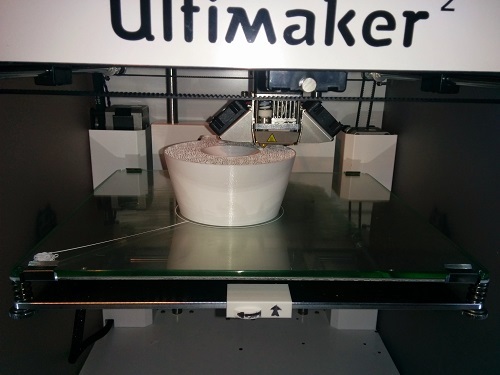

Yup – I run a webcam:

i was just going to say, i’m pretty thin on top, do you make them to custom fit?

The last time I had a spaghetti print was when a company sent me a spool of HDPE labelled as ABS. Fortunately I spotted it fairly soon as HDPE does not stick to glass, or anything else other than HDPE and PP.

The last major one was when a rubber glove got caught in the filament intake of my machine. That jammed the filament for a while which caused the print head to be lifted to the top of the machine as the extruder climbed up the filament. I haven’t had a print detach from the bed in a long while.

I do, but I also sleep. This week I did a 39 hour and a 56 hour job. I slept twice during both of those. Had it air printed just as I went to sleep, it would have been 6-8 hours before I checked again…

LOL – I don’t think any of us have not had that happen at least once

WOOOOOWWWWW. Gives me a great idea…

Before realizing the conversation… I thought this was your craft! I was like - hey that’s pretty good for a plastic planter! (I thought it was the “moss” base before you print the 3D flowers to stick in the middle)

My imagination can run wild at times…

Are you really a 3d printer person until you make a flying spaghetti monster?

Getting bed adhesion right is my biggest challenge. I’ve ruined print beds due to not being able to get a print off.

Good point – until you have a feathery mass of thread where a finished print should be, I don’t think you have really paid your dues

That was one of my biggest peeves when I had mine. They advertised it to be perfect every time whether PLA or ABS (without a heated bed!). They were wrong. Then came the painter’s tape. But as the plastic cooled it contracted, and pulled up the tape every time on anything bigger than a quarter. I was weaving tape across the board, wrapping it around, and it still warped and pulled up… just too much work, especially when you weren’t expecting it because it was advertised and a click and go type product.

Pfft. that’s amateur hour… When you come down and find your printer looking like this (and yes, that is hot-end #2 cooling fan along with a chunk of the X-carriage sitting in the base next to the heated-bed drag chain) is when you’ve really paid your dues (literally)… Nylon ALWAYS wins… (and thank goodness for air-print since the strands of nylon going back to the hot end, kept the glass bed from falling all the way to the floor and shattering)

Nothing is fool proof but they are getting a lot better. I have very few failures now that I have learned to dial things in. PEI print beds are a big help.

Maybe I’ll try again in a couple years after I’ve mastered the art of laser cutting.

After owning a couple printers for a better part of 10 years- I got sick of the BS and added a couple features to my DIY printer to avoid the cray cray.

PEI bed. Just do it. Epic stuff.

Mains AC headbed /w SSR. The need…for speeeeeed. (<2mins to 100C)

Mini Differential IR sensor with 5 point probing.

DuetWiFi for the Motion controlling.

Redesigned my part cooling fan.

E3D all the things. I use a Volcano (0.6mm nozzle) teamed up with a PT100 sensor and a couple of Titans. with 0.9 degree steppers @ 1/32 MS.

Simplified3D (Miles ahead of Slic3r - BUT this is equal to Ford vs Chevy or Mac vs. PC- Just use what you like)

One of the things I’ve added to my printer to avoid air prints was a filament sensor. I have a 1024PPR encoder just before the extruder that ‘watchdog’ the hotends inlet. Just after the spool I have a roller switch to make sure there is filament coming from the spool.

If the print is active and nothing happens (no movement on the encoder or the filament detection trips)it pauses the print. If nothing happens in the UI for 15 mins it pulls the virtual estop and resets the controller (which in turns kills the steppers, hotend & heatbed). I’d rather a failed print vs. half the spool wasted, big 4" ball of solid plastic on the end of the hotend or a fire.

I can’t see how that fixes air prints. Fixes clogs certainly, but air prints are working for all the world, except just not sticking together as the object you intended… Unless I am missing something here.

Whoa! OK, you definitely win…or lose, I guess

You’re right – slicer prefs are the holy wars of 3d printing, but I have a question (seriously).

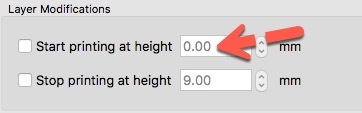

I bought S3D along with my UM2, but have never been satisfied with the output. For me, it has so many settings that even after 2 years I still just use Cura. For example, after the most recent update (UM2+ firmware, S3D v3.1.1, and recommended S3D profile), it seems to work perfectly except for 1 minor issue – all prints start about 2 cm above the bed (after leveling). ![]() I’d love to use their amazing support generation tools, but since S3D doesn’t allow you to save .obj or .stl (gcode only), I can’t import them into Cura. Any suggestions? (I’m happy to take this to PM or email)

I’d love to use their amazing support generation tools, but since S3D doesn’t allow you to save .obj or .stl (gcode only), I can’t import them into Cura. Any suggestions? (I’m happy to take this to PM or email)

This sounds like a strange setting issue. First make sure this is not set (under advanced):

Second make sure the right ultimaker is configured. Also take a quick look in the G-Code of the start script and make sure some weird offset isn’t being set (normally these scripts are well commented). That can often screw all sorts of things up. If neither of those are the issue, let’s PM and maybe we can figure out what setting is the problem. S3D is pretty good, but it is easy to accidentally get a wrong setting (one took me a week to find a corrupted pref) and I still have the build for my E3D BigBox showing physically on screen as a Lulzbot Taz6…