“Double” depends so much on the specifics of your cuts, but there is always some loss. The process of making a kerf adjustment makes it so the “matches” don’t fit correctly anymore.

It’s hard to describe or illustrate, but essentially if you are cutting a shape and its dimensions are very important, you compensate by cutting it slightly “too large”, and the lost material from the kerf makes up for the difference, your end result is exactly to size.

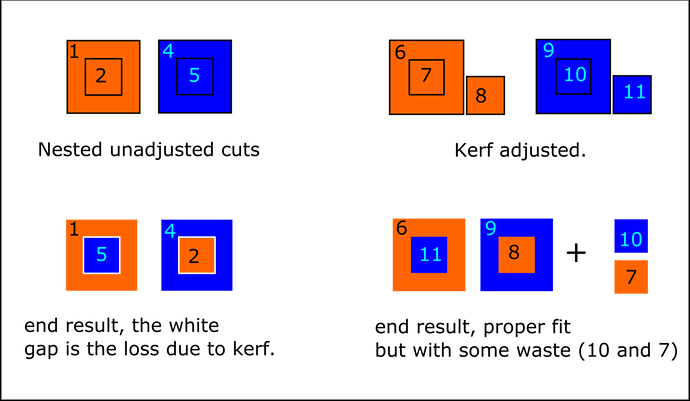

Here’s my bad attempt to illustrate:

On the left you have the straight nested cuts with the black lines representing the thickness of the laser (It’s exaggerated, but I’m trying to demonstrate here. If this were to scale, this would be a tiny part, the black line would be about 0.008" thick for most materials)

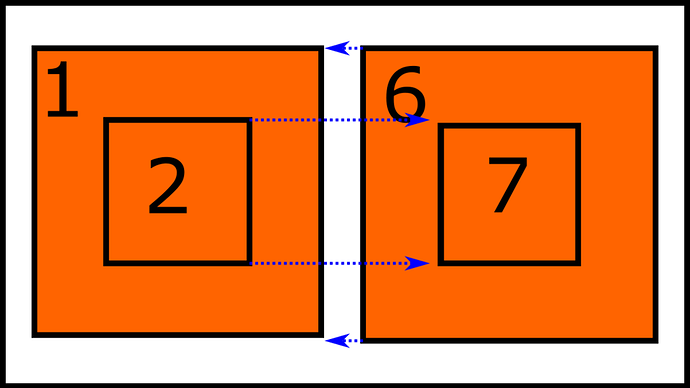

Details on the slight change in scale between non-adjusted and adjusted:

Note how 6/7 is a kerf taller and wider overall, and how 2/7 aren’t the same size anymore

As you can see the end results of the non-adjusted cut has a kerf-thick gap between parts. In order to compensate for that I use thestroke-to-path method, which makes for some too-small inner pieces (#7 and #10) which are loss.

I may be overcomplicating this, but these things will become pretty obvious pretty quickly once you start doing some experiments.