Saw this on my flipboard today, really want to make one now. Since I can’t yet, may be I can make one vicariously through @madebynick

http://grovemade.com/mobile/product/walnut-macbook-sleeve/

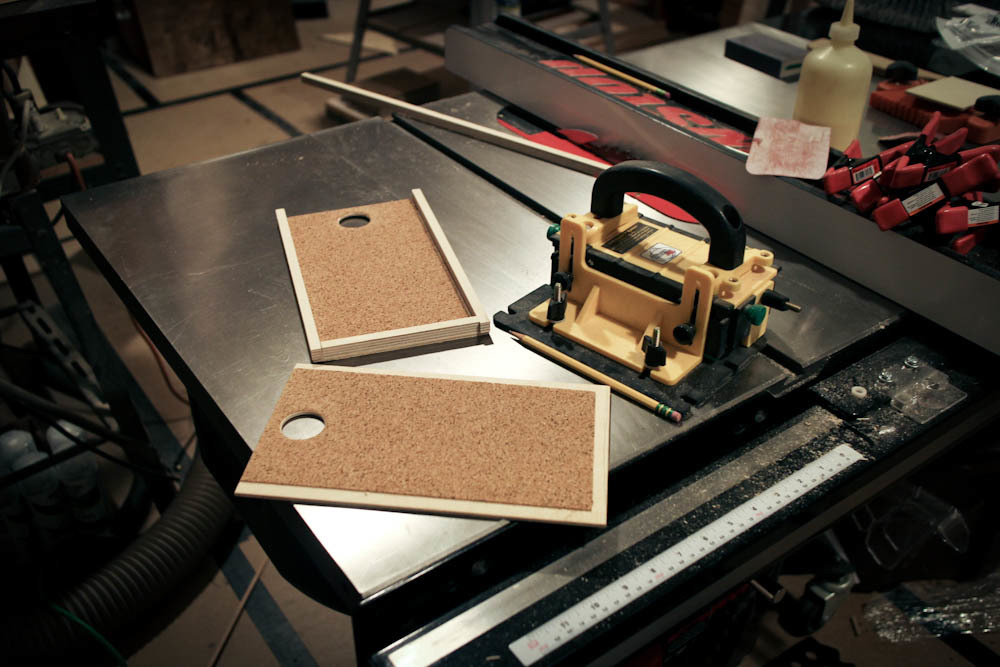

Here’s my heavy handed, much less sophisticated wood protection device for my apple thinger. I wanted a hard case that I could chuck into the car truck without worry. Something similar could be made on the GF by stacking cut layers.

I really like this! I like the no-nonsense ruggedness. Clearly, it’s not messing around. You could make these really beautiful with a laser-etched surface and leather strap.

Love it @Tinkeringmonkey!! Sometimes no-nonsense is the exact thing you need.

Nice! Did you need to line the inside with anything to protect the screen?

Yes, the inside is adhesive sheet cork. We used to make coasters and I’d laser cut cork circles (oh the burning).

So, how does cork smell?

Do you have a good source for it?

Nice work man!

We weirdly found it easy to get from Homedepot.com. Cork smelled a little burny, but not bad. I was impatient, so I’d cut at 90% power, but I’m sure some tweaking could get decent cuts.

This is a neat idea.

Hi @Brandon_R !

How do you think is that case done?

I think they first stick the wood to the felt and then they cut or engrave the wood. I’m trying to find the know how so i can start doing it with mi GF.

Looks like it may be similar to that wood blanket design floating around on Pinterest.

In this case, the wood was cut first, then attached to the fabric. I haven’t used a laser enough to know if it could be cut after, but that would be way easier if it were possible to cut the already attached wood without harming the wool underneath.

I suppose you could cut the shapes out of the center of the veneer like a puzzle, find a way to lift them all out at once, and lay them on the felt. Perhaps tape to lift it? In this way you might use the leftover outside of the veneer as a register to get all the pieces straight as well.

That’s a really interesting project. Seems like one would get a lot more utility out of it (softer, wouldn’t break when you got folded under yourself) by making the wooden pieces out of leather instead. A hard veg-tan would replicate the visual effect very closely and be far more durable.

We used to produce (in China) and sell wood iPhone and iPad cases with one of my other companies. You are probably ok with plywood, but keep in mind that wood expands and contracts a lot with seasons (90% humidity in the summer, 15% next to your wood stove in the winter).

We used solid wood, had ALOT of warping, cracking and an occasional trapped iPad with a case that shrank with the iPad in it!

My wooden(Vermilion) jewelers bench toolbox has a split on the two end panels. That tropical wood doesn’t care for the high desert plains of Colorado.

Being so dry, I use evaporative cooling and in the summer the cracks disappear, in the winter you can slide your thumbnail through it.

I’m not so into lasers yet either, but it could be great option to cut the wood after being attached with the wool.