My basic GF is deadly precise and I’ve never had to mess with it from day one.

I’m glad you’ve had such success. But every time I’ve approached GF about ruining a piece of work because it didn’t start printing in the correct place, the only response I get is they can’t guarantee anything closer than 1/4 or an inch.

I abandoned all hope of ever using the camera on my glowforge for alignment years ago. There are many work arounds but I would be great to be able to trust it. THis is one of the things piquing my interest in the P2. Please keep us posted on how it goes.

Sorry to hear. I am lucky I know. I can literally get within a hair of where I want it to cut.

With a good calibration, I can get as precise as I want to. Even cutting the middle of a piece with 1/16" to spare.

Glad to hear you can get so precise. Maybe you can explain how to GF help desk and they can change there stance on only being 1/4 accurate.

I think it comes down to something in their manufacturing tolerances. My first machine was so great in alignment, this one is terrible – off by about 1/4" to the right on the left side of the bed.

It’s possible that calibration could help me, but there’s some diminishing returns for me. In general I either don’t care much about alignment or I care very much.

In the cases where I don’t care that much, 1/8" - 1/4" of material doesn’t matter to me – the time I would spend fiddling with alignment is far more expensive than the square inch of material I’m “wasting”.

If I do care about alignment, no camera-based setup is going to be good enough for me. I need sub-kerf reliability, and the only way to really get that is with jigs. I’ve gotten very quick at jig setup, and I essentially never miss. It may take me 2-3 minutes of extra setup, but in terms of time that’s cheap compared to blowing even one engraving job. It’s also worth the time if I only have one shot at something, such as engraving onto an existing item like a box lid or something. Jigs all the way.

So yeah, I’m in that weird middle ground where the camera only needs to be OK, all my demanding stuff is beyond what the camera can do.

Everyone’s mileage varies here. My Glowforge is accurate enough for my needs.

The reason I’m very interested in (and appreciative of) hearing about people’s experience with the P2 and other machines is that I know my Glowforge won’t last forever. It has been very good to me and this community is like a second home, so all things being equal, it’d just replace it. But I don’t know whether all things will be equal when that day comes. Good to keep options open.

yeah, each of us individually is a very anecdotal point of evidence in a sea of 10s of thousands of machines.

An example I use to show what can be done. I needed 3" of material and what I had was a whisker over 3". I did take quite an effort as 1 degree of rotation off would mess up everything. but here is how it worked out…

Yeah, mine is that good. For a CNC tool with a .008 business end, I would be sorely disappointed with an “allowable” 1/4" accuracy.

There’s a big difference between what a machine can do, and what a machine is guaranteed to do.

“Able” to do is done by engineers…

“Guaranteed” is done by lawyers

I’ve both a Glowforge Pro and an xTool M1 Deluxe.

My view is that our Glowforge Pro has clearly an higher construction quality (it’s a wonderful piece of design, too…), nonetheless xTool is growing well and I’m currently a friend of many of their developers and caring team.

I purchased their M1 to have a smaller machine to keep at home (the Glowforge moved recently from my office to my garage/batman cave:) and honestly it works PERFECTLY.

With the optional air assist and riser I now use it more than the GF for basic stuff (not high quality), as even with simple uncovered materials the air assist gives me a perfect cut (under 4mm) and engravings with no burns at all. Something that I cannot do with my GF, where I can get better results, but I need “proofgrade like” TAPED materials (and it’s so bad proofgrade are NOT available in Italy…).

More, I suggest GF to “follow” their strategy on XCS (the software to operate all their laser products). It’s COMPLETELY FREE, working locally (so VERY fast… no internet needed…), and growing rapidly in terms of features. Obviously I make 90% of my complex designs in Illustrator, but it is SO DAMN USEFUL to be able at NO PREMIUM COST to make basic shapes, cuts, outlined texts,… They’ve even added a free generative AI function.

My humble opinion is that GF should give us all the design features for FREE, as well as very fast processing of… our designs, and keep on charging a premium subscription for design downloads and the possibility to sell own designs. Otherwise there’s so much of a difference to new nice machines like the P2 (it works perfectly, from friends that have purchased it → the super high placement precision - you can engrave a toothpick - and “serious” air assist are really useful).

I love my Glowforge since day one, but… cannot afford the Premium subscription for my usage. And I now feel a significant usability difference between my GF Pro and xTool M1, where the second is honestly better.

Secondarily - like xTool did - consider engineering an optional real air assist for our GF (the M1 air assist was added later, and works like a charm): it would significantly help for working with non taped materials (even improving the cut speed and reliability - with no fumes at all). I’ve studied the shape ou the GF Pro laser head and… it could be done.

Give it a thought, super Dan ![]()

Nice comparison/review. What kinds of things do you make in the M1?

The website wasn’t immediately obvious just how big the cutting area is (I had to dig down and looks like about 15" by 11").

The power is listed as 10w, which seems pretty low for cutting 3mm woods etc. How do you think it fares?

One of the guys I follow on YouTube has a 20W D1 Pro and it appears to be pretty slow. Cutting 3mm plywood was noticeably slower than the GF.

Depending a bit on the material I have even made a second pass at high speed to smooth the engrave and remove any charring

The M1 10W is clearly a different machine. But with “real 10W”, if I need cutting some drawers, boxes, (medium quality) keychains, cardboard, EVA foam (majority of my non-professional works)… with its air assist (no burns for cheap untaped materials) and easy software… it’s a snap. Staying <= 4mm it does its job with very good precision. And fast enough for me.

Clearly the M1 cannot do transparent acrylic and thicker widths. And the bed is about 10cm less wide (appx 40x30). But the machine is even very small in comparison, and can stay closer to my (smart)work desk (even with the rotary attachment for cups). While I had to place the GF Pro downstairs in my garage.

Clearly the new P2, with its nice, free XCS software, serious air assist, precision, power, wider area and excellent support (if I need a function… they hear and make it, for free as well - such as when I needed to save params for my custom materials)… today would probably be my choice for a new machine.

I hope Dan & team will drive improving our GFUI with a free plan for normal design stuff and - potentially - an air assist mod (and proofgrade materials in EU/Italy for a reasonable cost, like xTool already does).

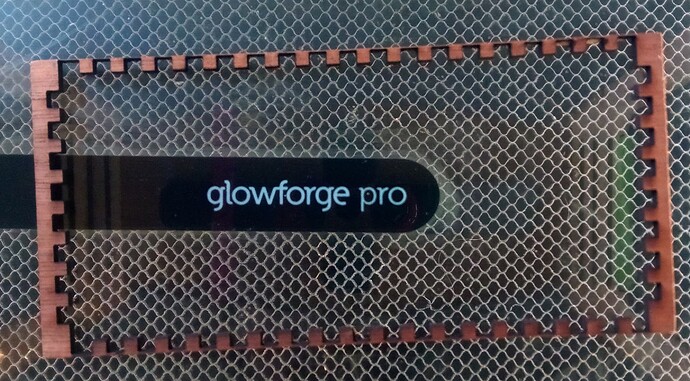

Here my machines, to check the dimensions:

What an awesome workspace and look how clean everything is too. ![]()

ahah thanks. This is usual… at the beginning… ![]()