love it!

I don’t believe that the Z axis has to be limited to the distance from the head to the bottom. I think the distance from the bottom to the lid glass is much greater. Still pretty small comparatively, but more useful than 2".

I also think they’ve got some smart people there that can figure out other stuff. I think they mentioned 3d printing and inkjet because those are pretty achievable. I think they didn’t mention CNC because wood bits flying around in that case might not work out so well. Cricut type of setup or something, maybe just has a clamp to lock it on after it’s attached to the magnets.

There has been discussion elsewhere on the forum about how Glowforge is calling it’s machine a “3D Laser Printer.” It came up again in the topic that I continued.

What’s the origin story for Squishy?

I think that’s correct. I think it’s being used as the number because that’s what the current material thickness allowance is for the laser head and honeycomb bed. But if I were to decide to put a 3D extrusion head in there, it’s possible to turn the 3D printer on its head. Instead of a bed that moves down as I build a part, how about a head that moves up from the fixed bed that is sitting under where the honeycomb sits now? That’s 5-7" as far as I can tell from seeing the machine at Makerfaires. That’s actually not a bad build volume. Making a 3D extrusion head that rides on a snap-in magnetic mount would require some motor assemblies and things that I would think are doable with what’s out there today - certainly inventable by someone who is doing what GF is doing today.

But that doesn’t make me think that a vinyl knife or some way of putting color down (inkjet or airbrush) isn’t something that I’d want first ![]()

The name bothered me during the preorder campaign, and I didn’t completely buy the explanation that they thought the name was more accessible…

Until my mom started calling it a laser printer, and she has never seen the promo stuff or looked up the website. I described it to her, and she calls it the laser printer thing.

Then again, she also asks me to ‘print’ stuff on my digital cutter.

I guess if material goes into a machine and comes out different, in any way, it’s been printed in her mind.

Yep. They must have some Z motion control in the laser head now in order to do the flying focus automagically. This would just be an extension of that. And if they make the laser tube easily removable, you could mount all manner of motors and filament routing, etc on that part of the rail without having any concerns about moving mass.

Think about a build volume of something near 20"x11"x7" - nothing out there like it.

I shall call him Squishy, and he shall be mine, and he shall be my Squishy. – Dory, 2010

unless you build sideways (which there’s nothing really absolutely against) the hard limit for a 3D printing arrangement will be the height between the bottom of the case and the gantry.

Which is about 4" as far as I can tell.

Hmm. Can anyone else make a compelling argument against sideways?

Sideways? You mean like Speculation on the Expansion Port? (sorry to link again if you already saw that)

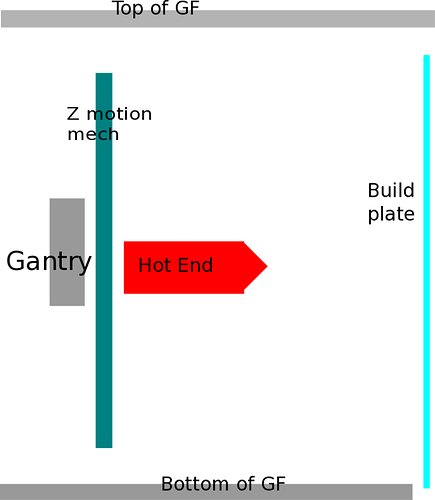

I missed that. No, I mean really sideways. Something like this

In theory if you have good cooling or use certain filaments you won’t sag. Some of the overhang rules and the within-layer sequencing will be different. But I don’t think it’s completely insane per se.

I am thinking about calling mine, “The Great White Whale.”

Elusive and you want to murder it? Those feelings will pass.

Ha, the unobtainable, mythical beast.

Good point, I hadn’t thought of that. Of course, you could add some fasteners to the router head to hold it on tighter. But then again, if you’re going to do that, why not just use fasteners from the beginning? Seems like it’s going to be most suited to low-load applications… unless they beef it up with mounting strategies that could have been used from the beginning.

I thought about sideways but had no idea if it was actually feasible. Would the new layers hang on without a base? I suppose not a lot different than something with a small base that expands out and overhangs? How does that work on most 3D printers?

Gravity?

Don’t give @dan any ideas - or he’ll delay the next shipment date because the GF can’t cancel gravity yet…

Usually filament sticks to the base of to the layer below because it’s molten plastic being squished against something that it’s compatible with. And with nonstandard tools like the 3Doodler, there’s no a priori problem with attaching stuff from the side (I’ve done it with some amount of success). Usually that adhesion is helped by the fact that each layer of plastic takes a while to cool down, and sorta lets the next layer melt into into – but that means the plastic can be soft and sag. (It depends on the plastic – some stiffen just below melting, others stay soft at ridiculously low temp).

Meanwhile, though, I realized that all of us have been imagining (more or less) a standard gf configuration for these addons. For some of those that will be true, but for others, since it’s not a laser any more it won’t need to operate with the lid and the front door closed. So a 3D printer might have much more vertical space available to it (if you could get around the issue of having to fit the prints under the gantry, which you might with a big offset assembly and some counterbalancing (read up on Bowden extruders…).

Also, because the current head is not light, and the Y-axis is designed to move the tube around, I think the x-y drive mechanism probably has a long more force available to it than we would usually think.