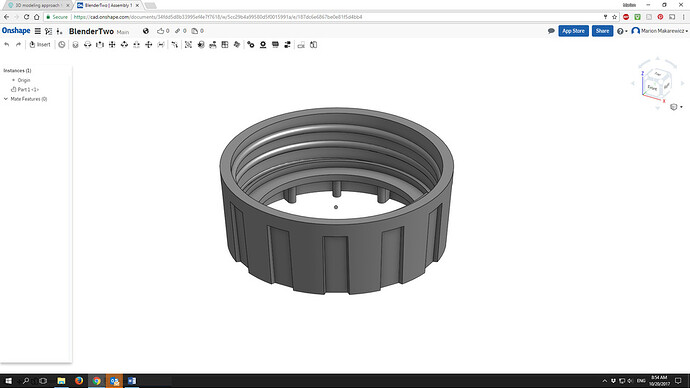

I was modeling this blade holder base for a blender in OnShape. I’m a novice but I can pretty well recreate any shape now. I made a very serviceable and accurate reproduction of the original blade ring. I used circles and extrudes and drafts and lofts. It looked great. It took a long time, all the while using a top down view.

After it was all completed, I was looking at the part from the side and it dawned on me that I needed to make a side profile and do a revolve. What had taken a couple hours in figuring out using drafts and lofts, took five minutes in side profile revolves.

The experience I gained from figuring out lofts and drafts was invaluable because I did need to use them to create the fixture detents so the base doesn’t spin inside the machine housing. But now I understand the purpose of design intent a lot better and have a sense of what tools are most efficient for me.

Like @mpipes, perhaps the word “best” isn’t the most useful way to describe any procedure. It is such an empty term. Once again, beware of labels because they simplify complex realities. Time-saving could be more accurate or most flexible method, or easier to make parametric.

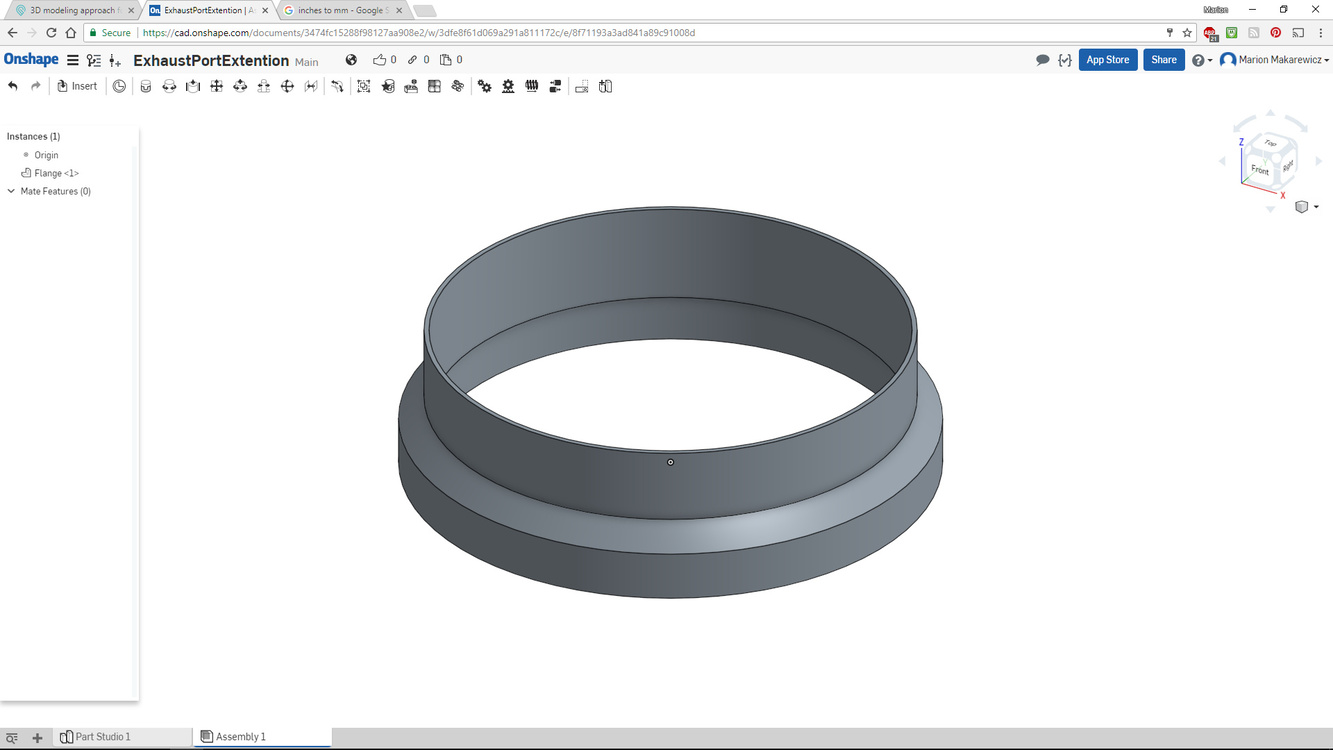

In any case, I need to think about alternative construction methods, but first I have to be aware that they exist. Here is my OnShape document. I have to think about some of the design elements and procedures, but it’s defined well enough now that I can go back with the calipers and get better dimensions.

Comments and suggestions welcome.