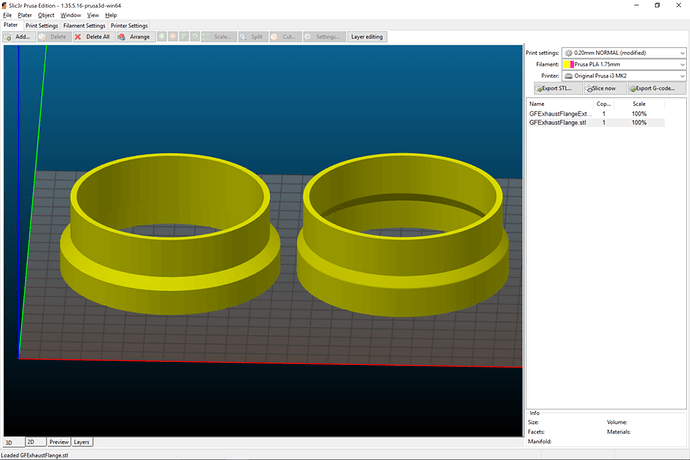

I loaded OpenSCAD and did @palmercr’s flange extension. I note that my STL and his STL have different settings for line segments making up the curves. I haven’t paid attention to this before, and really didn’t pay attention to it in my other models and renders. When I finished the print, I thought, yikes, it’s not as smooth as I’d like. So I’ll look through my OnShape defaults to tweak the STL.

Yes I reduced $fa to 1 to make the picture look nice. I normally use 6 for printing. The filament smooths out the facets, ABS more so than PLA.

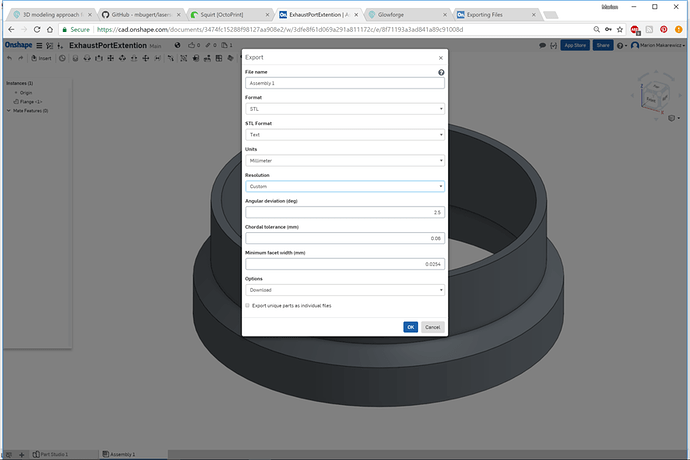

Trying to learn the terminology used for this aspect of 3D modeling and STL export settings:

Facets and chords. That’s what I need to know. It’s in the export popup. I’ve just been using medium resolution. Fine still has an angular deviation of 2.5 degrees. Putting it to 1 degree smooths it out.

Doesn’t create too much additional print time.

Thanx for the linky, this is something I need to read up on as well.

Depending on their capacity and construction, they could be causing the problem. Either by leaking themselves or by creating back pressure by not having enough capacity.

I’d get rid of the boosters. Even if you’ve got a couple of 90 degree elbows in there you shouldn’t need boosters. And as others have noted they leak as their housings are not usually airtight.

Not especially. I first encountered it in the discussions about using Sketchup when the circles weren’t circles but were joined line segments to approximate circles. They are technically called chords. That is a controllable setting. You don’t pay attention to it but then when you start exporting the SVG or do modeling and notice the facets, you say, “what gives?”

Anyone who has learned modeling/design software needs to know these things, but when do they need to know for what purposes is a big question. I’ve been printing for four months now and haven’t needed to look at the export settings. Now I have a use case that requires me to understand it. I put an STL out for public consumption. I’m surprised really that someone didn’t comment on the resolution and appearance of the facets in the print. Anyone who has never seen a 3D printed object or used modeling software would look at it and say, “why does it have all those lines and flat surfaces on it? I thought it would come out smooth as the Venus di Milo’s bottom.” Yeah, welcome to the reality of FDM printing.

It’s not a very visible part since the extension is covered by the vent tube and the base flange goes into a recess and it’s behind the printer. No need to look pretty. But still.

The facet angle can be quite high before you get much error between the chords and an ideal circle. The eye has the ability to see facets due to the change in the brightness of the reflection rather than the positional error. So you need more facets for it to look good on a screen than you do to print with FFF.

I don’t see facets with $fa = 6 with ABS but with more shiny and less viscous plastics it can need to be lower or you can see them. And if you were say milling it in brass you would need a very smooth curve. Probably the same when laser cutting a shiny plastic.

I keep it as low as possible when 3D printing because there is a maximum number of facets per second when printing over a serial port.

Man, would love to have some time with you in a workshop and go through some of the myriad complications that go into a print. Right now I have to trouble shoot why the support material isn’t sticking to the bed. I’m looking for settings, but not quite sure where to start. The skirt will stick fine and the first layer sticks just great, but the support seems to tear up at the tips of all the lines. then they curl and get in the way of the next layer. Something to do with the withdraw procedure. Just haven’t taken the time to search for the answers. Do I need a raft for the support material to adhere to? Other prints I’ve had have had very good support material with no initial rats nests without any rafts.

Thanks for posting this here @marmak3261 !

You’ve done enough 3D models of stuff, have you considered posting them onto Thingiverse? (It’d make finding all of them in one place much easier!)

Yes, I need to get the workflow started to do that. I’ve remixed many things into OnShape and have quite a few objects that are just interesting and just haven’t done it. Honestly, the thought of another username and password just about makes me throw up. I spent three hours Friday afternoon and evening battling an AT&T/SBCGlobal sub email account. I have tried various times to set up sub account and use Outlook as the client or Thunderbird to see if it is server based error or client setup error and have been unsuccessful. The AT&T management consoles for this are abysmal and opaque. An hour between chatting with support and then being handed off two no less than three technical specialists and the third handoff ended with the prime, first landing spot for the voice menu for AT&T support, you know the one that says, “Welcome to AT&T, para espanol opprima dos” and then you get the sinking feeling that you have just been passed back down to the lowest circle in hell. I had given my call back number but didn’t get any call back after 45 minutes.

Finally just decided to try to set it up through the Yahoo/AT&T web email portal, which I also loath. As soon as I did the account setup there, I was able to finish the Outlook setup for the sub account.

You know, when a management console says, add a sub account here, and you follow all the steps for verifying and getting the security questions written down, because you are setting them up for another person and they have no idea what their favorite movie is and can’t name a single actor when you ask them, have no favorite song, and had no childhood friends, and think you have it all set up because it says, congratulations, you have set up your email account, you should now be able to connect to it through any modern email client software and then it does not work and gives no error message worth a hill of beans, it makes me curse out loud in a way that is only reserved for red lights that stop you seven times in a row as you pass through an urban through way that is anything but, and you just as soon never have to enter in a username and password ever again.

I know, it’s irrational, but PT Barnum was able to empty over crowded rooms at his museum by changing the exit sign to read “To the Egress”. Everybody left in a hurry to see just what this strange new creature looked like.

I’m sorry you had so much trouble but I have to say that I enjoyed your writeup of it.

I feel your pain. What keeps me pulling out large patches of hair is keeping my 85 year old mom safe on the internet. She likes to cruise crafting (you see where I get it from) YouTube and blogs, and order things on Amazon, etc. And of course the elderly are particularly juicy targets for the scammers. Fortunately she has a healthy skepticism and runs stuff by me first. So far, so good.

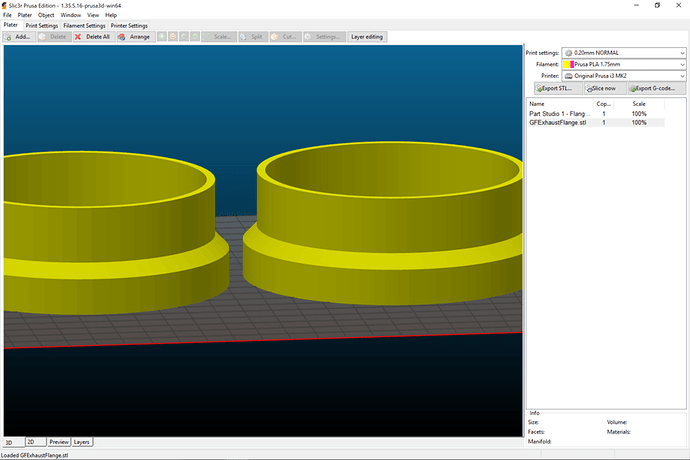

If you are referring to the particular model you shared above, and support is giving you a problem, you can actually get away without it using it here. You can flip the model over and have the smaller diameter as your first layer. The 45 degree overhang that you get would be gradual enough that it should print without a problem.

Yes. Thank you. I am continually baffled by my obtuseness which takes the first view of something and can’t let go of that. Dang confirmation bias at work agai. Seriously, why does my mind work this way? I’ve had problems before that were solved by rotating the object. In this case I plopped it down as I built it and then promptly stopped thinking about alternative print positions. I ask that question now from a design view: what is the best orientation for a good foundation sketch of the model. I don’t ask that question before I slice it in Slic3r often enough.

While it doesn’t solve my continued issue of garbled first layers of supports, it does solve it for this model. Thanks.

If you could post a photo and perhaps a video of support being laid down I might be able to diagnose the problem.

Ok. Thanks. I’ll work on that later this morning.

Didn’t even bother with the movie though I was set to film. The first layer of support went fine with only a slight curl at the end of the retraction steps of the lines.

I often experience the first lengths of filament as behaving differently from the inner part of the roll. This was brand new PLA just out of the vacuum seal. MatterHackers. I’ve seen this behavior before. In any case. The support lines stayed firm and adhered with only the slight curl. I had not reprepped the bed either and it worked. Go figure.

Hard to get focus on the black flat bed with an iPhone 5s.

I am not sure it is retraction that is problem. It looks more like it curls up where it makes a U turn. Normally zigzag infill gets anchored to the outline but when it is support with no outline that doesn’t happen.

I would try a higher temperature for the first layer so it is more fluid than plastic. That allows it to make corners more easily. Slowing down the first layer support might also help.

Ok. Will examine that first layer which I pulled off and see what movements are indicated by the curls. I’ll check into that first layer temp setting. Might be something with my head/extruder needing to completely normalize temp. And a combination several things.

Like pancakes, second prints always turn out better for me. Thanks for the help.