2021-11-03T02:00:00Z

In full disclosure, I have been a vocal critic of how the Glowforge Pro passthrough feature was over-promised and under-delivered. By the time I was invited to be a beta tester for the passthough feature, I had moved on to other thing and was not able to try the auto align feature. Previously, I was able to make some parts with manual alignment that were satisfactory but not perfect. Yesterday, I saw a recent post from someone who was having trouble with the passthrough auto alignment and support asked them to do a test with the smooth curve stencil design. I decided to give it a try as I had some new projects that could make use of the passthrough feature.

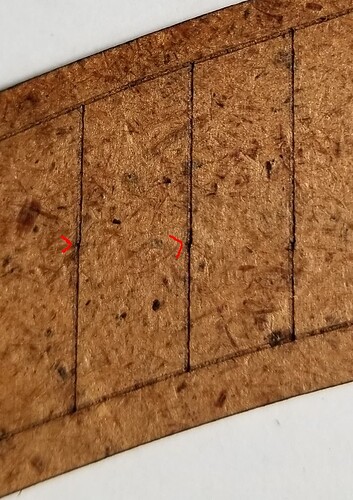

I set up the design with the arrows aligned on the dotted line as described in the note and made the first cut. I had it auto-align and the lines as the ends were close, but the middle was not. (I probably could run the alignment process for my camera.) It would not be possible to manually align, so I had it auto-align a second time. Hoping for the best, I had it do the second cut. The result was almost perfect. The only visible defect was in the vertical scores on the left side of the stencil.

There were no similar offsets in the other scores or cuts. Overall I would say that this

passthrough test was 99 44/100% perfect.

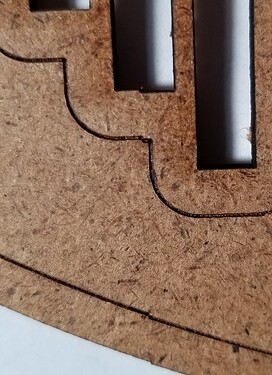

I also read recently that some people were having problems with alignment on later cuts when the second cut matched perfectly. I expanded the stencil to take up most of a 20" sheet and rotated the design 90 degrees. Here is a comparison of the two.

After the first cut, I only had it do the auto-align once and the results were less than perfect and arrows are not necessary to see the defects.

On the second and third alignments, I had it do the alignment twice and the alignment was perfect each time (photos not shown). It would appear from this limited test that

doing the alignment twice gives a better result. If this is the case, it would be better to have the final result from the first alignment be equivalent to two tandem alignments.

I hope that this information proves to be useful as the results that I obtained from two tandem alignments are perfect or near perfect. If this is always the case, then I can use the passthrough auto alignment with confidence in the results.