I am designing a marble machine gizmo that will be made of mostly clear acrylic. For the lift chain I want the pin that connects the links to pressure fit into the outside faces. But I am concerned that after laser cutting the holes they might be susceptible to cracking or breaking from the pressure. I know cast acrylic is best for taking a nice engrave. But is there a difference strength wise between cast and extruded? Is this a good case where annealing the plastic would be helpful?

I look fwd to seeing this.

Would it distract too much to make the chain from Delrin?

Yeah I was thinking of that. It would also be better for smooth movement where the parts rub together. Certainly an option.

You could use heat to expand the link or cold to shrink the pin for fitment without the force required for assembly.

Or just get the pin to be a snug slip fit then put a drop of acrylic welding solvent on it for a trouble free part.

Somewhere somebody (@dan ?) did a hole in acrylic with a bunch of angled cuts around it to give it some give. I wonder if that would be useful here.

Oh yeah I forgot about that, it was in one of the fidget spinner threads.

Annealing the acrylic after cutting works pretty good for keeping the cracking down.

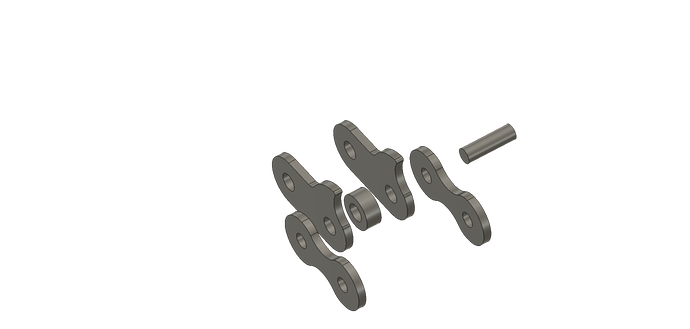

You got me curious so…

1/4" acrylic rod for the pins. It actually measured at .250" dead-on. (Yeah I happened to have some laying around LOL). Buzzed these to length in the glowforge too, but the beveled kerf really shows. Unfortunately even though a saw will make a perpendicular cut it will leave the ends frosted.

Medium Clear ProofGrade acrylic.

The press-fit parts have holes at .242" diameter. I took a stab in the dark and nailed it first shot. LOL It’s tight enough to take a good amount of force to press in by hand but not require any tools other than a block of wood or something to keep your fingers from getting beat up. They go in with a snap, and dont back out easily at all.

The rotating parts have holes at .250" diameter.

The pieces all move pretty freely long as you don’t clamp the press fit faces against the rotating faces. I think I would still put a teeny drop of weld solvent on the pins in the press fit pieces just to avoid them moving if there are any temperature fluctuations. Never know how things may move or walk while under load in use.

I gave you one heart on the forum. But 10 hearts from my heart!