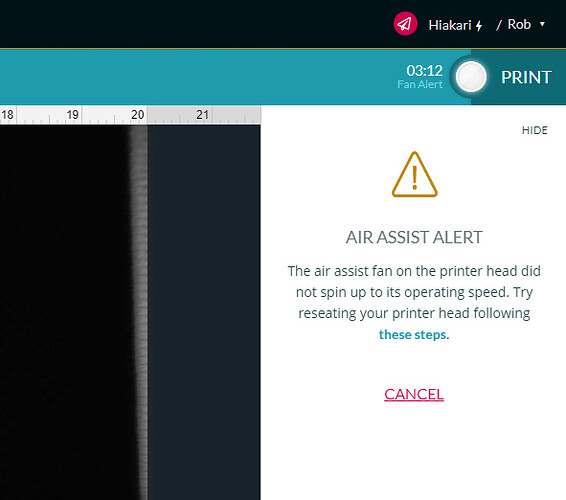

I had no problems all morning and then a job stopped and I got an “Air Assist Alert” and the GF stopped.

I followed directions:

- Cleaned contacts - replaced head - print job stopped

- Removed head and AAFan assembly - blew it out and cleaned the fins and surrounding parts - fan spun easily from the beginning - replaced all and ran print and the result is shown in this video. Again, the Air Assist Alert.

When I examined the fan assembly, it didn’t seem particularly gummed up.

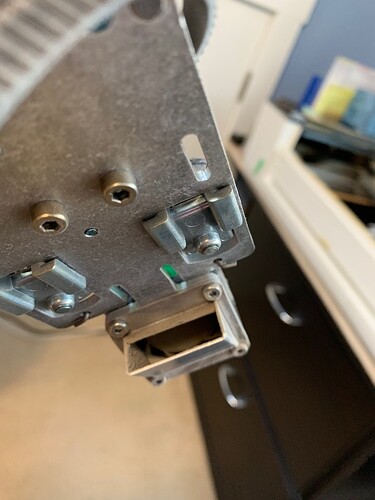

I checked and the pins spring back reliably. I cleaned the fan from the top and from the bottom. I didn’t unscrew the fan from the carriage.

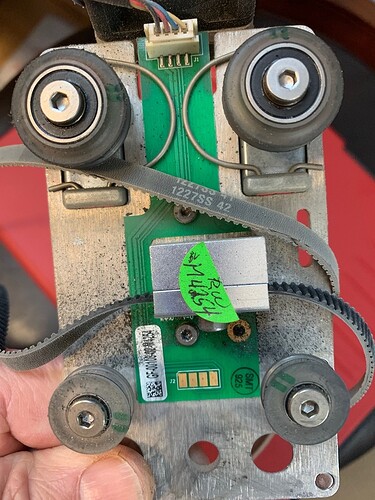

The still pix are from before I did my thorough cleaning and blower duty.

The video is from afterwards.

Please advise.

PS: Is that green tag an indication of a reworked part? Just wondering.

The lifetime on these little boxer fans isn’t that great. Particularly in a “dirty” environment where crap can get in to the bearings. It could just be that the fan is tired. It looks tired… Judging by the number of wires that go to the fan, I’m guessing the GF monitors the fan tachometer and if it won’t get to speed the GF will fault even though the fan is in fact turning…

1 Like

As one who has had many problems with that fan, including far worse gunking up than I see there. I found (with the Glowforge shut off) that I could get a used C-pap hose into the exit and attach it to a shop-vac and it would pull a lot of air through the fan spinning it up. At which time I would pump in Alcohol hand sanitizer that would dissolve the toughest gunk. Leaving the shop-vac running for a half hour or so after. All traces of the cleaner were gone, as were all traces of gunk, and the fan would work quite well until it needed cleaning again.

I have not seen this to be the official method but it worked well for me up to the point other issues caused the need to exchange it,

This is what it was at one point:

4 Likes

We’re you using any neodymium magnets to hold down your material? Were any near where it stopped? I’ve seen them stop the little fan from turning.

5 Likes

Thanks, but mine doesn’t seem to have anything restricting it. I’m not a heavy user, so I’m a bit surprised that it’s having an issue.I did take alcohol swabs and hand cleaned each fin and the surrounding area before trying it the time in the video. Hmmm

I was. I’ll try it without them.

I removed the magnets and the cut proceeded fine.

- I’ve used these magnets numerous times with no issue.

- The fan didn’t always stop right by the magnets.

- Who cares as long as the fan doesn’t have issues from now on.

Thanks @jamesdhatch! You beat official support with an answer.

Thanks also @rbtdanforth and @randy.cohen for trying to help.

7 Likes

Same here. I think it’s always been happening but when they turned on the monitoring if the sensors now see it’s happening then it shut us down.

It doesn’t stop right over the the magnet because I think it takes time for the fan sensor to be polled to see it’s stopped or slowed.

The irritating thing is that if they let it proceed it would spin back up & you’d be fine. Instead it shuts your project down.

2 Likes

I complained and was told to try again, So apparently they turned that off on mine as it did that and kept working for reasons I only now understand why it stopped, a number of my magnets have steel plates on top and so the field overhead of them is much reduced. I think that some steel flashing that would be thin enough to cut and shape by hand would not only protect the magnet more from blows but perhaps the fan as well.

I bought what I have thinking it was aluminum flashing at Home Despot but have found that magnets sticking to it gave a different set of uses.

The job shutting down is a big issue for me. It wastes material. I’d rather get an obnoxious warning and give me the choice what to do.

As it is now, I’m concerned about starting any large jobs because I don’t know when the nanny will turn off my tool. Can you imagine if you had an Internet-connected table saw and the dust collector vent clogged and the manufacturer turned off the saw mid-job? Some may say that’s a bad analogy, but since all analogies are imperfect, I think it’s right on. Now if there was a warning for the laser escaping the case…or flames beyond a cutting flame…

I may try what @rbtdanforth suggests and cap my magnets. I use the wooden pins most of the time, but I had a bow in the middle of my Delrin.

1 Like

That’s why I use them. Not all warping is on the edges or can be managed by trying to flip it so the edges lift instead of the middle.

That “one gotcha” handicap was my first thought even before I experienced it. I had the problem of the fan in what I now realize was a magnet issue and that time it did not shut down. It was weird that the fan would stop in certain areas of the tray but I did not make the leap that there was a magnet there.

1 Like

Regarding your Air Assist Alert fan issue, I’m glad you figured it out! As per the Glowforge manual, only laser-compatible material should ever be placed inside the Glowforge to avoid interfering with operation.

As for being able to continue prints when the Air Assist Alert is tripped, that’s a great idea! I’ve passed your feedback along to the team.

I’m going to close this thread. If you run into any other trouble, please start a new topic, or email us at support@glowforge.com. We’re here to help!

1 Like