Hello everybody,

first of all thanks to the “Glowforge” staff for creating a wonderful project.

A big thank you also goes to all of you, users of this forum, for sharing experience, tips and tricks.

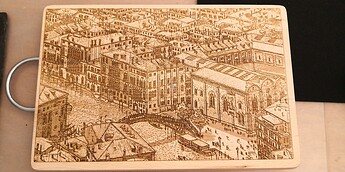

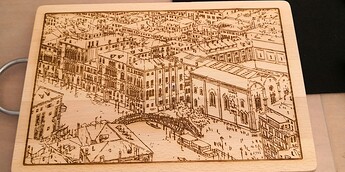

I’m writing from Italy, a few kilometers far from Venice. What you are reading has been translated online by big G, be patient ![]()

Well, moving on to practical things, I living in an apartment I had to necessarily build a box that would limit the noise but at the same time manage the exhaust fumes.

Probably I got carried away a bit, many mistakes were corrected during the race, but in any case I’m satisfied with the results obtained. One above all, being able to work close to the GF.

53db when cutting and 42db on idle, measured near my desk, about 1.5 meters (5 feet) from right side of enclosure.

Some details:

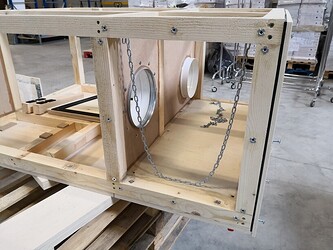

The upper part consists of 3 boxes:

First 18mm of plywood and an adhesive sheet of lead rubber (10Kg/m²),

2 equal circular holes, one for the forced extraction from the engraver and one for the chamber (the last probably useless)

1 hole for the bypass

1 rectangular hole on the left for incoming air directly connected to the base of the Glowforge

1 rectangular hole on the right for additional inlet air

1 small circular hole for various cables

Second 15mm of plywood and 40mm sound-absorbing panel (100Kg/m3)

Third in plywood 10mm;

2 additional 14mm fans to ensure a good air flow inside the chamber;

The inlet ventilation (the 2 fans located at the base on the right side of the machine) was channeled using a 20mm sound-absorbing panel;

The lid is also made up of 3 levels with a total weight of 45Kg (about 100 lb);

The lower part consists of a wooden frame

with a first filter composed by 3 layers a metal meshes and double polyester filters

then a filter composed by 6kg of activated carbon

all connected to the extractor (Blauberg 20mm - 950 m3/h)

smoke extraction between the upper and lower part is guaranteed by 2 10mm pipes (the second is operated by an electric actuator)

the structure was then closed using 6 removable 10mm plywood panels and 40mm sound-absorbing panel (100Kg/m3)

all managed by a control panel connected to the electrical panel

there is still something to fix … but I was too impatient to see him at work ![]()

If its worth doing its worth over doing, cool end result.

If its worth doing its worth over doing, cool end result.