Not sure where to post the idea but since the head comes off so easily why not create a CNC head that could basically convert the Glowforge into a Carveforge.

It’s been brought up, and among other issues brought up, was the fact that it DID come off so easy. You can’t create enough down force.

Duck tape!

Trivial problem - a foldover clip that locked the head to the plate would be easy to implement & use. The Shopbot has a similar method of locking the power connections to the spindle.

The biggest hurdle is a Z-axis. In addition to a router you’d also have to have a mechanism to raise & lower the head (& mill). The power needs of a router are also more than the laser head so that ribbon cable won’t be sufficient for the amperage - would need heavier cabling and some sort of drag chain arrangement instead of the folding flat cable (which is an elegant approach for a laser).

Duct tape and bailing wire can fix anything.

The stepper motors in the glow forge are ridiculously Underpowered for a CNC machine. They are tiny nema 17 motors. Probably Under 40 oz. The stepper motors on my CNC machine are nema 23 269 oz motors and still considered a hobby machine. Putting any kind of resistance on the linear set up of the glow forge would be a disaster. And let’s say it did work. A first chunk of anything that goes flying would shatter either the lid or the laser tube.

And don’t get me wrong nema 17 Are fine for a no resistance laser head

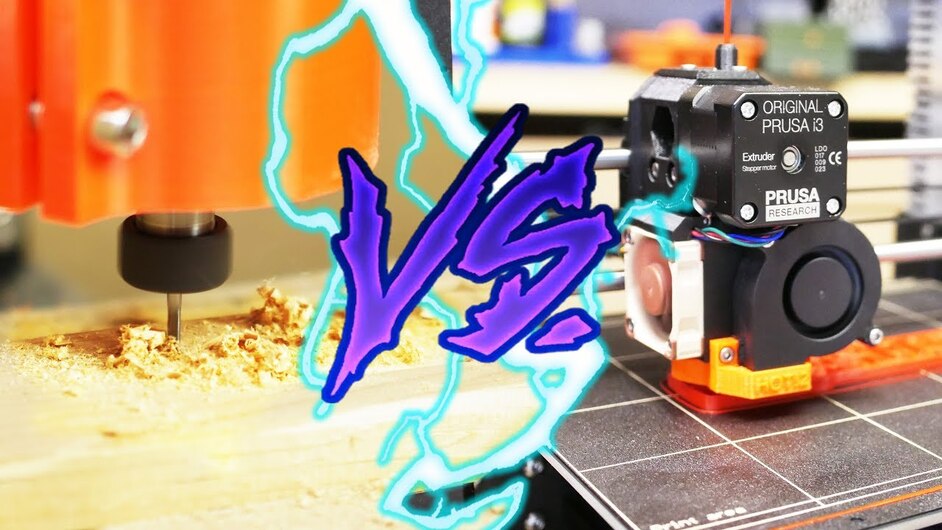

There have been some attempts but it’s not worth it. For a laser cutter, you want to move the head fast and don’t need any force at all. For a CNC mill, you move the head relatively slowly and need quite a bit of force, meaning that the frame and motors need to be much more stronger and heavier. So you either end up with a very slow laser cutter or you end up with a really wimpy CNC mill. There’s also the issue that a CNC mill generates tons of powdered wood (or whatever you’re cutting) which gets everywhere unless you have a dust collection system on the milling head, which is more mass.

Well it appears that I had a really good bad idea. Thanks for the feedback!

Oh, would love to see what Red Green would do to make one!

Another point, in case the machine not robust enough isn’t a deal breaker.

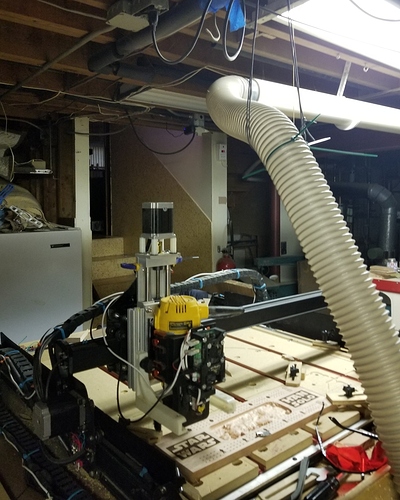

If you ever used a CNC machine you would see the problem. Messy is an understatement.

We can have problems removing smoke if things are not spanky clean.

No way would I want chips and trailing slivers (metal plastic or wood) all over inside the box. Resin build up is the current worst case.

First thing that popped to mind…

Yup. Note the 4" diameter dust collector line. goes straight to a dust shoe. And it’s not a large computer fan on the other end. It’s a 1.5hp DC dust collector taller than I am.

On the other hand, a really high-res 3D scanner/profiler…

This topic was automatically closed after 32 days. New replies are no longer allowed.