Looks great…What settings did you use?

Thank you @jrryw13

Fun test. Thank you for your settings.

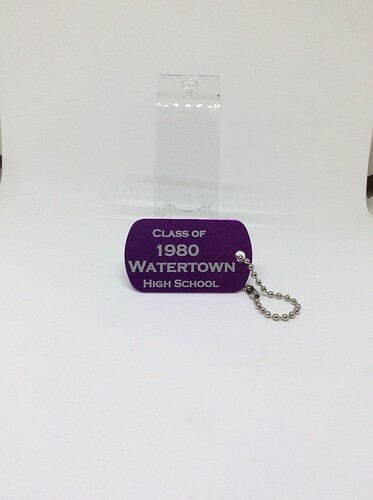

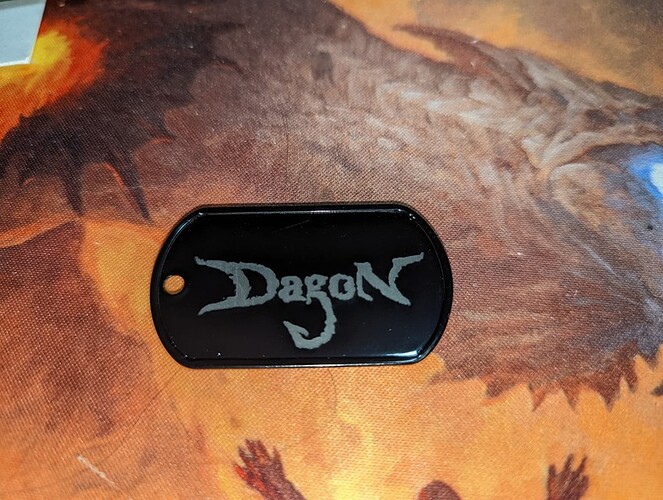

I wonder how much of a difference it makes. All of my AA tags I’ve done at 1000/Full/340 and gotten sharp results.

Next one I do I will try your settings and see if there is a difference

The key for anodized is “enough” power but extra power makes no difference. I always run high speed and high power.

The critical factor for them after power is LPI. This is one where high LPIs make a very real difference. In organic materials you have issues with high LPIs just over-cutting previous lines and sometimes even degrading the end result. With anodized aluminum I’ve found that increasing resolution increases perceived quality all the way up the scale. Where I tend not to go higher than 225 on wood or acrylic, I start at 340 for aluminum and will often oush it higher.

Everything you just stated is exactly what I’ve always believed to be true.

Same settings I use.

Thanks for the info. Next time I will ramp up the speed

Generally, IMHO, unless there’s some sacrifice of quality, or 1000 doesn’t do the job, I always try to stick with 1000 speedicles. It’s rare I need to slow it down. No need to waste my time.

Speed is also my controlling parameter. I only slow down when full power & 1000 (or 500) doesn’t do what I need.

“I want what I want when I want it!” and slowing down just makes me wait ![]()

I ran a couple more tonight at high speed and high power. Higher LPI. A little cleaner look better speed of job.

Great Idea

I’ve always done 1000/100/340…sort of the same as you. Apparently, anodized aluminum is very user friendly to different settings.

Hi everyone,

does anyone have a sample or “jig” layout to do multiples a a time?

Like, slots to lay 30 dog tags in at a time so it keeps them straight, and ready to go?

thanks for any ideas or help!

Heathen Axes

Thanks for the info on this thread!

What is used to cover or mask these when printing?

You don’t need to mask anodized aluminum.

Sorry I’m slow I have not logged in a while. I have never masked anodized aluminum