I’m back with another Fusion360 question! I think I can work around this one but I haven’t found an easy way yet.

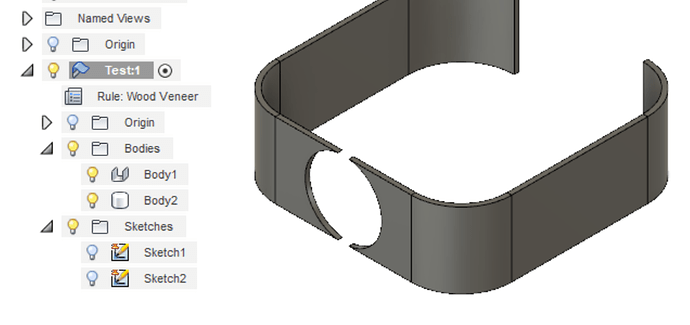

First, setting the stage: I’m working on more iterations on the project that I built the recent test box for testing how veneer bends:

On the real project, I’m going to end up with at least a couple of veneer joints so I am designing what I want to do.

The basic design is using the sheet metal tool to model the veneer so that I can unfold it and create the laser pattern - so far so good. It is essentially just a long strip/rectangle (and will be a couple of them on the real model). I then have a pattern that stretches across the entire height of the veneer and I use it to cut the veneer with the idea that I’ll cut that pattern in a different wood veneer and piece it together - still having joints (and having more, in fact), but “hiding” them by making them a design choice.

My problem: when I make the cut, it correctly creates two bodies but only one is still a “flange” and the other is just a normal body, which means I can only unfold the one (and seem to have no control over which one is left as sheet metal). I’ve poked around the internet but have failed to find anyone doing this (weak search-fu on my part). Any ideas? @Secret_Sauce? ![]()

A picture:

And a simple test file in case someone wants to experiment:

Test cutting veneer v1.zip (78.4 KB)

Thanks in advance!

-Jeff