I don’t have snapmark but it seems like it would make weeding iron on transfers easy. Has anybody tried?

Never bothered printing any transfers to test after attempting to cut regular heat-transfer material and finding the laser less than ideal for the task, especially when compared to a good plotter.

Check out this thread: Can I make iron on transfers?

Edit- Didn’t have anything to do with alignment though. The snapmarks, printed onto the transfer, would allow great alignment. The actual cutting was the issue. Someone else had better luck than me, but only with certain colors.  I’m fine with letting my plotter continue to take care of that for me.

I’m fine with letting my plotter continue to take care of that for me.

i’m not sure what you mean. snapmarks means good printing alignment. can you give me an idea of how you think that will help with weeding iron on transfers? i may be missing something.

Well i guess the question would be if you could print the snap Mark on the transfer paper and have the glow forge understand it. If so you could then weed inside curves and such easily.

if you can print on the paper somehow, GF should recognize it. but i still don’t see how that makes weeding easier.

Oh, you mean having the laser blow away the material to be weeded? I bet you could, but you could end up with islands in your design, unless you could zap the material away leaving a clean backing… which doesn’t sound likely.

LaserFlex is supposed to work like that, but someone around here tried it and couldn’t get it to work with the setting Glowforge gives us.

If you are printing to heat-transfer material, and want a shape more complicated than a square, you will need to do some cutting and weeding.

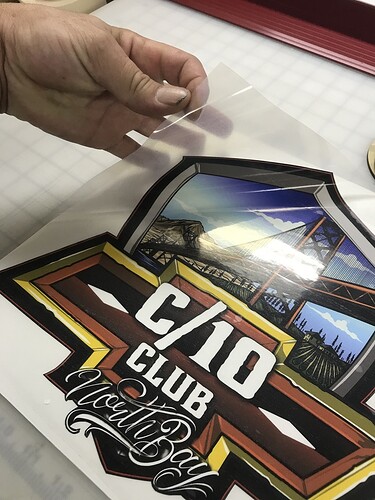

Here is a transfer that has been printed, cut with the plotter, weeded, and had transfer film applied:

and then applied onto shirts with a heat-press:

I find that it is easier and faster to do this with my plotter than with the GF, but I still have to add registration marks to the print file for the plotter to read. If I was attempting to do the same thing with the GF, I would use snapmarks instead of the “Graphtec 4 Points Type 2” registration marks that I normally use (which look like little right angles)

i guess i’m thick here. i don’t see how the cropmarks help with weeding. i see how they help with alignment.

Not thick, just not being as loose with interpretation of the word and making assumptions in the same way as I have been:

My assumption was that @Birdman3131 was using the term “weeding” to refer to the entire cut and weed process. So yes, the snapmarks would only actually help with aligning the cut, not removing the excess material. If they have been cutting transfers by hand, or struggling with a plotter that didn’t read reg marks well or at all, having the GF do that part of the process would be very appealing.

So, strictly speaking, you are quite right. Snapmarks would not help with the weeding itself. They would help with aligning the cuts, which are necessary in order to produce something weedable.

ok, i can buy that.

What did you print with, what did you print onto, and what plotter for cutting? ![]()

Printed with an Epson SureColor S40600 onto Siser ColorPrint Soft Opaque and cut with a Graphtec FC 8600.