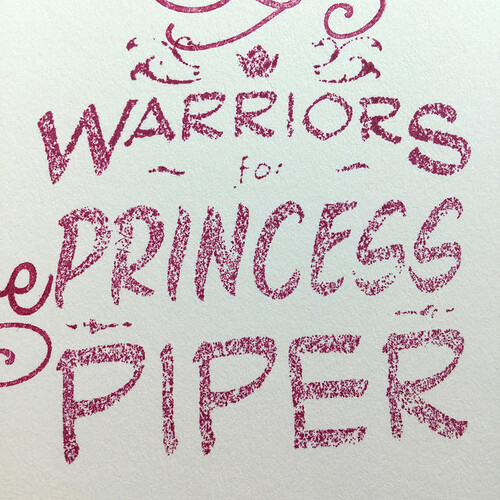

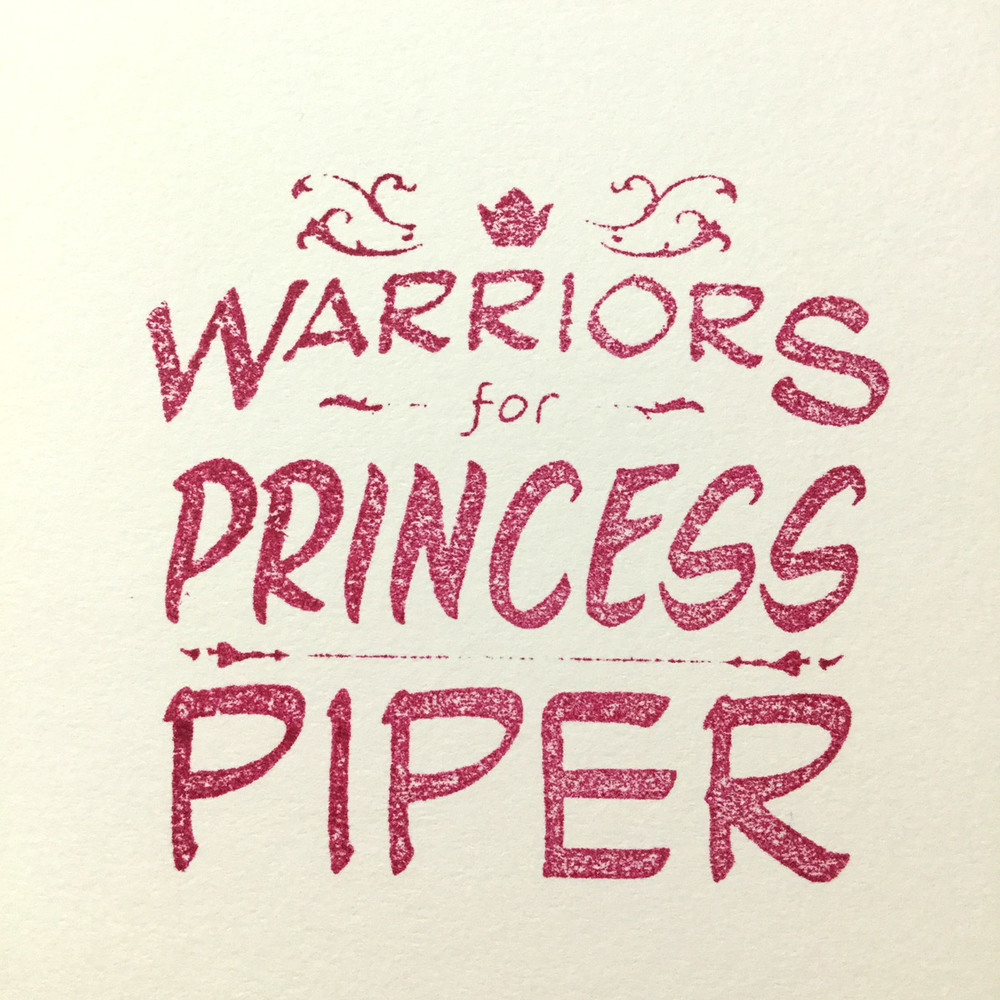

One of the reasons I ordered a GF was to make my own stamps and/or stamps for other folks.

Over in this thread, no one could successfully determine if the Inventables lino was laser safe, but there was a comment regarding ArtPrint Linoleum from McClain’s in Oregon that has laser safe lino. And lino they have! A grab-bag of quadrilaterals for 9 bucks! The only problem is… no one has settings for this yet. And it’s weirdly curved…

I tried the settings mentioned here(10/175 - am I correct in reading that as Power:10, Speed 175), but they must have been for softer material, because they barely made a dent in this stuff. I mean, they dented it, but it wasn’t denty enough for a good stamp.

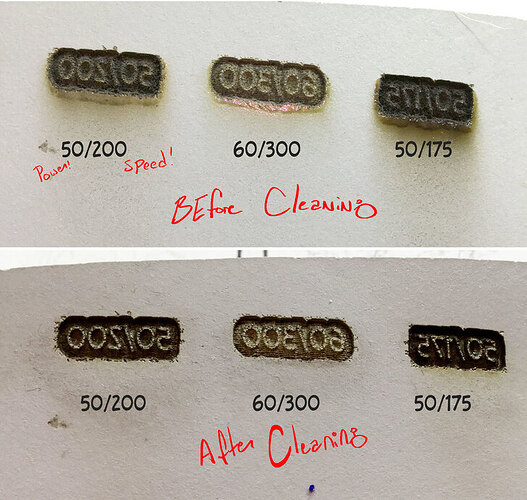

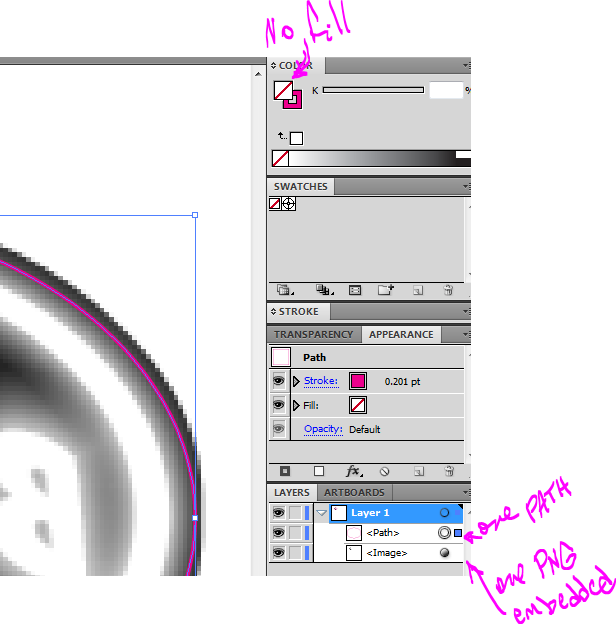

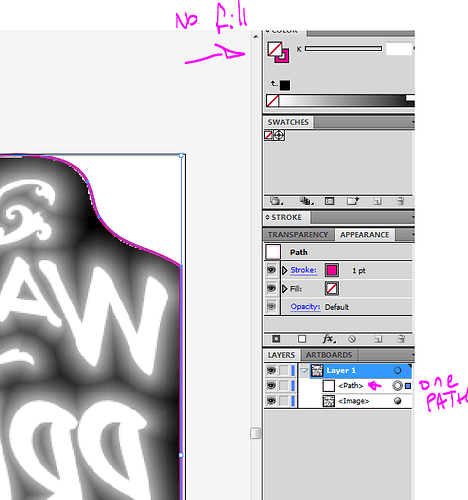

So i threw out random numbers and tested them. I cleaned them with Fast Orange and it worked pretty well. LPI for below was 225 and grayscale set to VARY POWER with Min Power 5(this=Mistake)

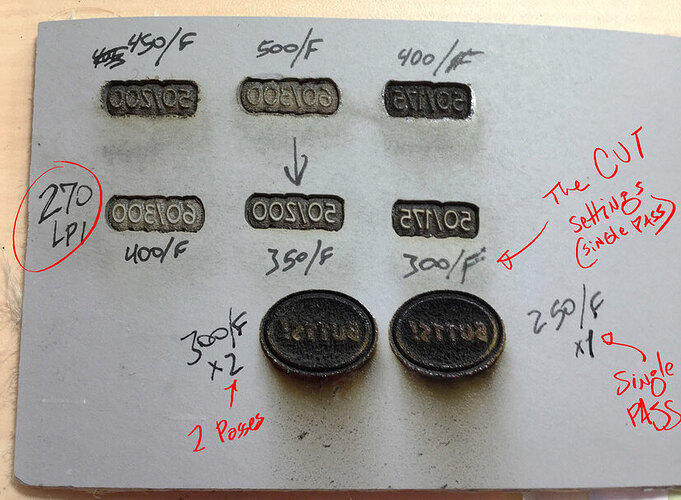

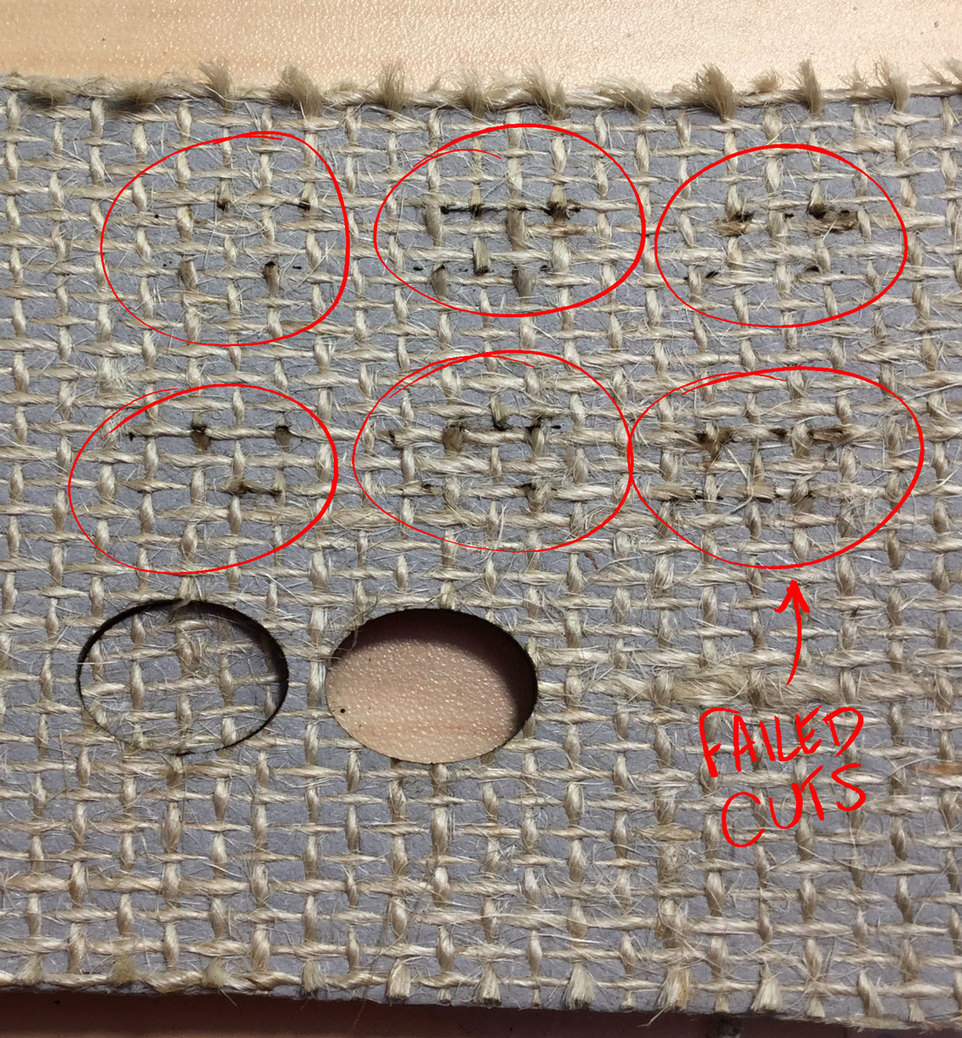

Eventually I fixed my mistake and turned the Min Power to 0(as I should have left it in the first place) and then set the LPI to 270, but I still could NOT cut through the stuff.

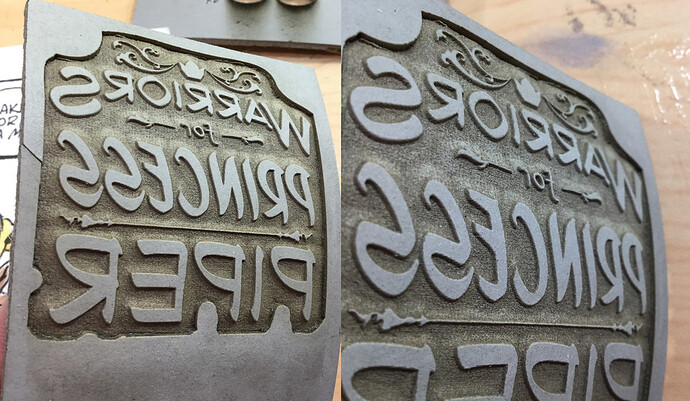

However, the 200/50 settings were looking promising, with a nice slope from the uncut lino on top(i followed this tutorial), so I started messing with cutting speeds and powers.

Finally, at 300/Full at 2 passes and 250/Full at 1 pass it cut through.

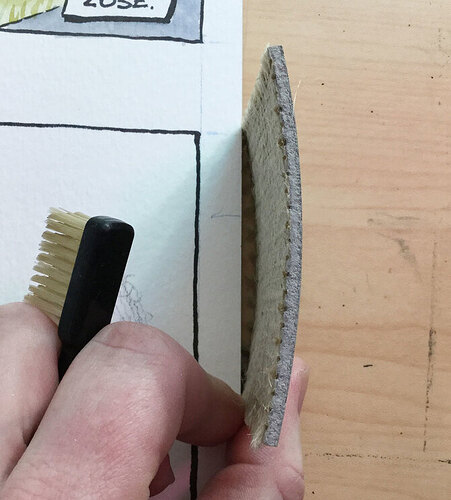

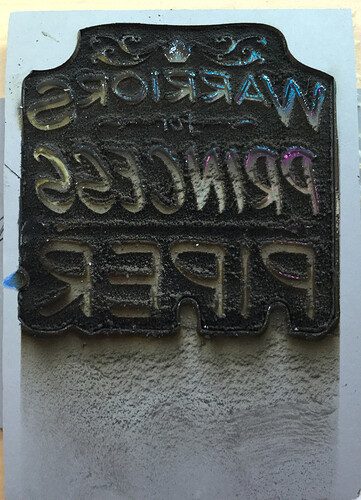

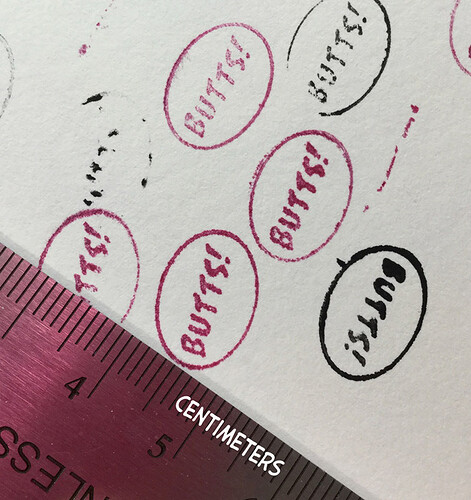

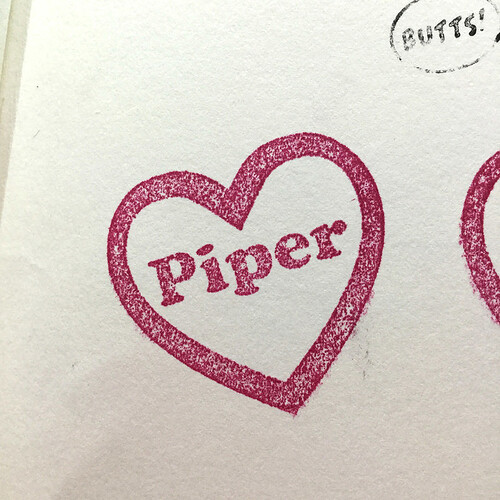

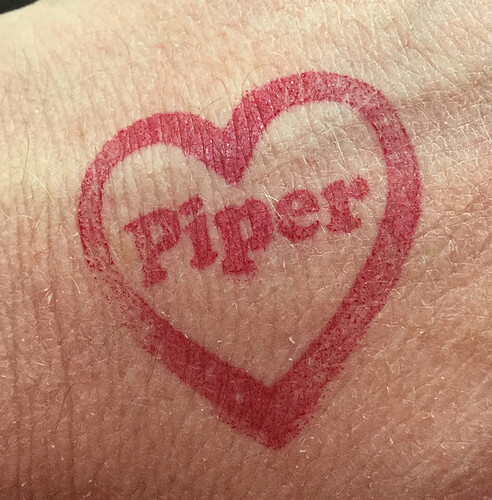

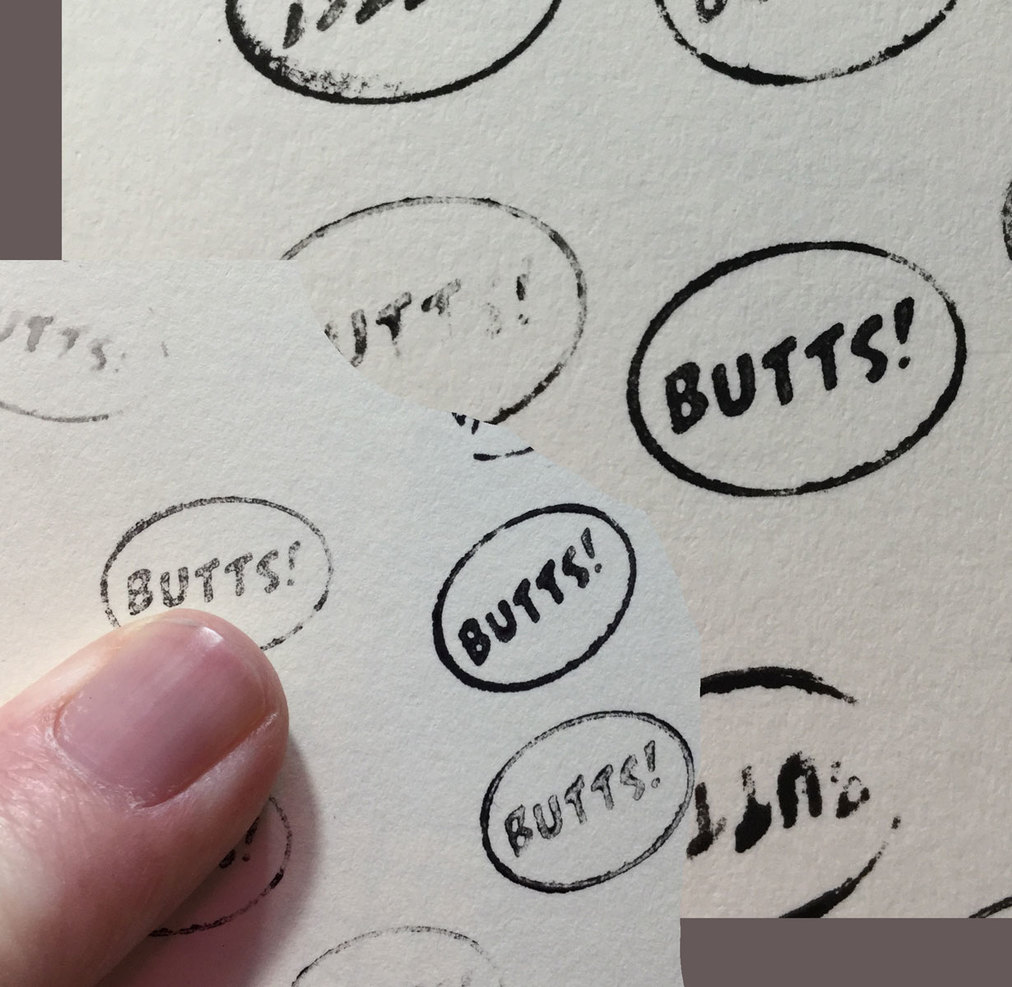

Time to make the test stamp happen. That’s my pinky finger in the photo. Despite the blurry photo, it removed quite a bit of material between the oval shape and the letters. And there’s ink all over 'em too.

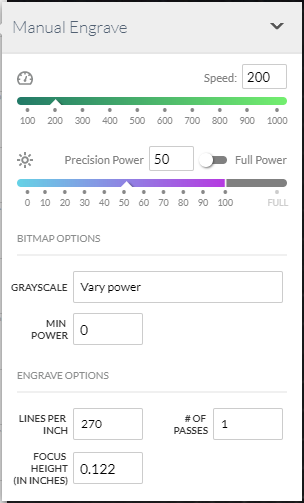

TL;DR: Engraving ArtPrint Linoleum, natural, no PVCs, blah blah from McClain’s in Oregon, settings that worked rather well: 200/50; Grayscale: Vary Power; Min Power: 0; 270 LPI

To cut it: I had most success with 300 Speed/Full Power, 2 passes.

Now about that wicked curve…

I ran it under hot water, then pressed it between some heavy objects and then ran it under cold water while holding it as straight as possible before putting it in the GF and starting the engrave as fast as it would let me.

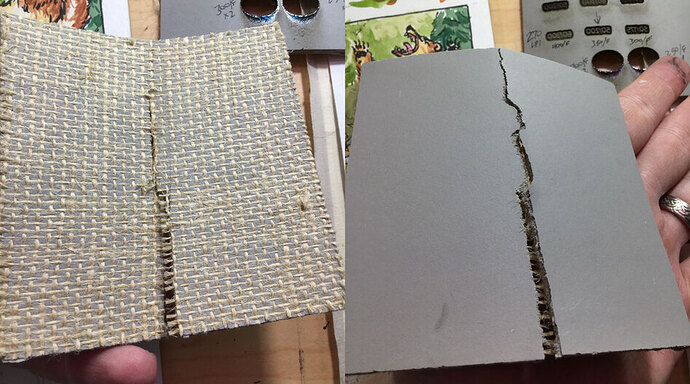

When I tried cutting some of the strands on the back and then folding it the opposite direction…

Maybe if it’s warmed up first it could work.

Anyway, good luck if you want to try this. You’ll also need to clean a bunch of stuff in your GF afterwards. I just ran the ACTUAL stamp i needed to make and that fold-down panel is filthy.

Will post pics as soon as I get it cleaned up.