Unfortunately, it’s part of the learning curve that each person has to experience for themselves, so I wouldn’t get too upset about it. (We’ve all done the same thing multiple times.)

There’s just no way to be absolutely sure something is going to cut through 100% of the time, even with Proofgrade materials. (And it’s very unfortunate that it happened for you right before a show, so that’s got to sting.)

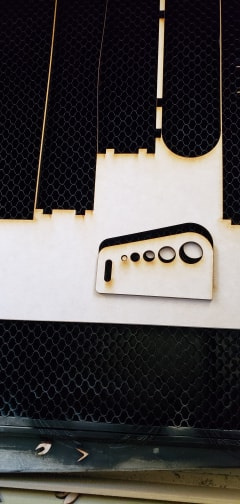

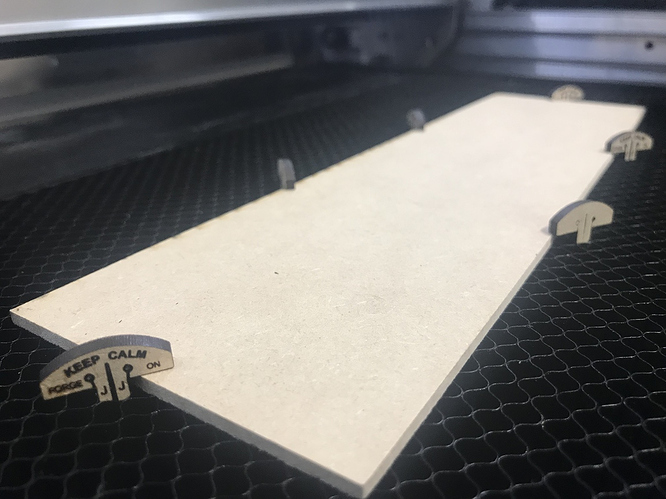

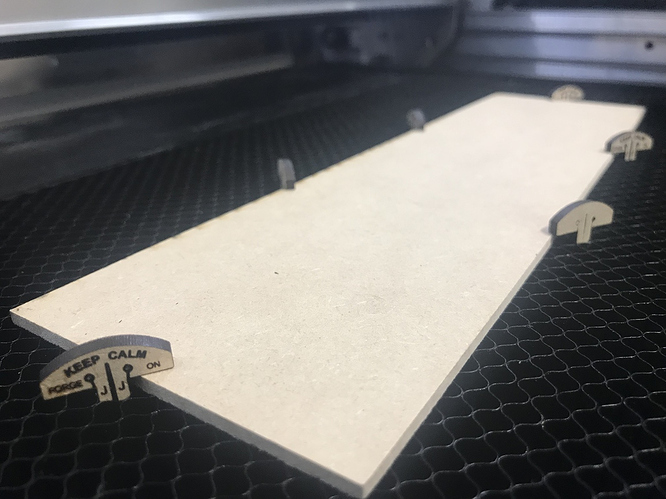

Going forward, you aren’t going to have the same thing happen, because you’re going to pin the material down, every time, even if it looks flat, even if it’s Proofgrade, because even Proofgrade can warp and bow a little bit in different humidities. And when you release the strain inside of wood by cutting things out of it…it warps. (It just does better than most other wood provided elsewhere.)

These free Honeycomb pins can be cut very easily from scraps, and they do an excellent job of pinning the material down flat so that the chances for complete cut through are dramatically increased.

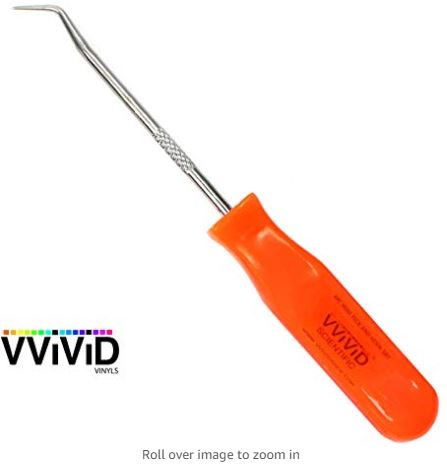

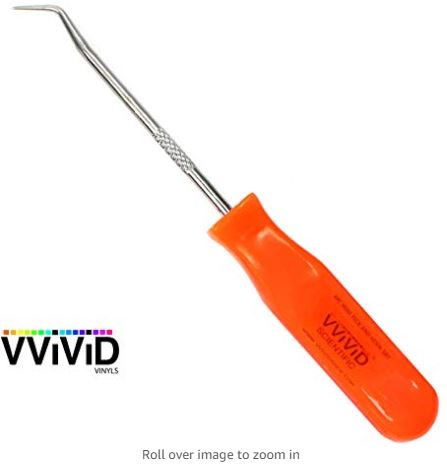

And you’re going to check for complete cut-through using one of these Vinyl Weeding Picks before you move the material so that you can send a second cut to finish the cut before removing it from the bed if you have to.

It’s one of the best $5 accessory purchases for the machine that I’ve found…I use it to check for cut through every time I use the machine, and stopped losing material to incomplete cuts.

Another way to go, which some people prefer to do, particularly if they live in a high humidity area, or if they have recently entered a high humidity season, is to just slow down the cutting speed by about 5-10 points. Going just a little bit slower leaves the beam in contact with the material longer and burns a little more material away. Don’t overdo it or you will widen the kerf too much.

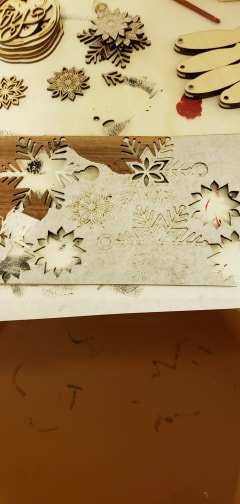

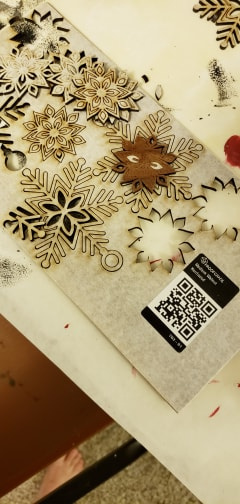

(Slowing the speed is often necessary for tight detailed designs to make sure the machine has enough time to cut all the way through…you don’t want to go too fast on those, and even the defaults can be too fast for certain designs.)

Hope you have better luck with the next cuts. Those tips should help.

There are a lot of really experienced and helpful people on this forum, and you can learn a lot if you’re willing to consider that maybe when things go wrong it’s not always the fault of the wood or the machine.

There are a lot of really experienced and helpful people on this forum, and you can learn a lot if you’re willing to consider that maybe when things go wrong it’s not always the fault of the wood or the machine.