What does the bottom of the glowforge look like? Is it molded to the sides of the case or is it a separate piece?

Don’t have the time to look for it right now but the bottom is an integral part of the case. According to dan it also provides rigidity to the overall case. So if you cut it out with a reciprocating saw you may have to reinforce the plastics. That doesn’t mean it might not snap into place during assembly somehow.

If its removable, I can just make a mold and cast another piece which I can modify to my liking =). And depending on the clearance you might be able to use the intelligent alignment to do an engraving on a very large piece that might be way too deep to ever fit in the glowforge.

I got to peek at an early 3d printed prototype case during the open house. The only way I knew it to be 3d printed was there was a guy standing next to me who said he worked for the printing company.

They entire bottom half looked to be one piece, with all the mount points for the innards printed in place. I am assuming that the final plastic from the injection mold will follow a similar pattern. If so then you would be hard pressed to mold a similar unit with enough precision. Better to look at cutting a hole and reinforcing it if necessary.

the great thing about molds is that if done correctly, are very accurate. It would all come down to how difficult they make the case to take apart, because I would hate to damage it to the point where it didnt go back together. If however it does come apart easily, you could make a mold of the entire piece, split it into two(or three: walls, bottom support, bottom opening), make some attachment brackets for the 2/3 pieces you now have, and reattach with a removable bottom. I really wish I could just see a photo of one without the tray.

If the Y gantries are at the same height or higher than the top of the cutting bed, that would open up the possibilities for some serious modification. Just install some handles on the side and plop it down on whatever you want to engrave. Want to engrave a table top?.. plop 'er down. Want to engrave the roof of your car?.. plop 'er down. haha

Being injected molded, I would expect one piece construction.

Few things I enjoy more than pondering existing engineering and how it might be innovated.

I will spend a lot of time initially (hugging) scrutinizing and indoctrinating myself on the machine’s construction and abilities - existing and potential.

As time passes and experience accrues, inevitability I will be inspired by an idea to further the machines capability. (I can’t help it, “baby I was born this way”)

I know I am not alone in this affliction, and I look forward to the creative ideas that spring from the fertile minds of others here in the community.

I have a T shirt that gives an accurate insight to the learning curve, no - curse experienced by a tinkermiester like myself…

If you take something apart, and put it together enough times - eventually you will have two of them.

(Alluding to the left-over parts)

NIce! Thank you!

Oh wow, that takes me back… Some good perspective on how far we’ve come in such short time.

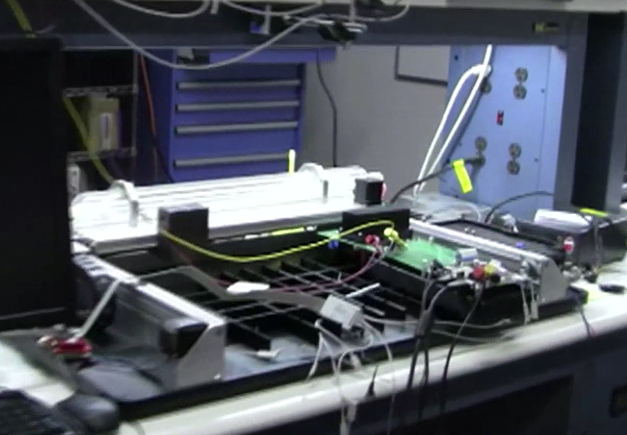

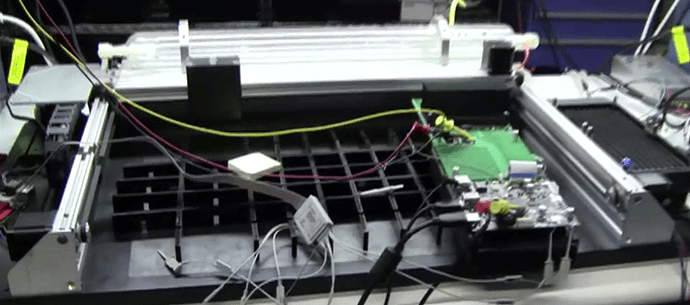

Looks like one of my power supplies just before the extinguisher came out.

You heard it here first. rpegg was running a lab when they invented extinguishers. ![]()

Soda water extinguishers.

I never knew Soda water needed to be extinguished.

How else do you stop the bubbles?

I thought they stopped because they were closer to the sun… Hmmm… Now I know…

I remember the ornate brass cans those old extinguishers came in.

The church office of one of my previous parishes was a 100 year old house. No one could live in there and and we just used it for rare meetings and such. There was a brass extinguisher still there in the stairwell. I didn’t snag it before leaving, but thought about it. We had a big auctions to sell off the contents and there were lots of antiques. Anyway, to bring back the focus of the topic, soda water and a splash of home made cherry wine vinegar on ice. It’s amazing.

Unfortunately for modders, the entire case is one piece (minus the glass top and front plastic doors). We sometimes affectionately refer to it as “the tub”.

Bit of trivia: there exists exactly one black tub in the world (they were out of white plastic when they shot it). @aeva called dibs on it though so I’m afraid you’re all out of luck.

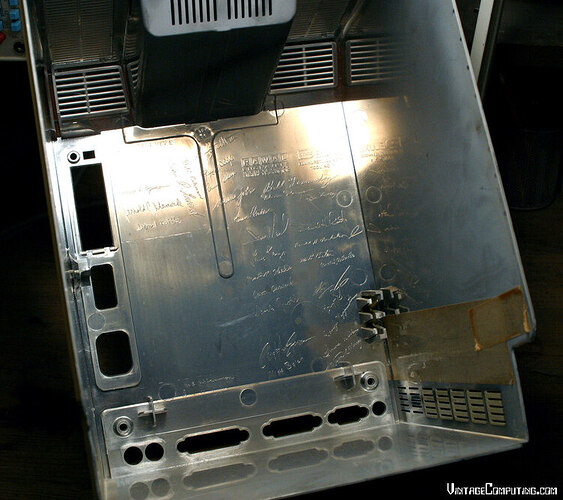

I remember taking an original Apple Macintosh computer apart and molded inside the plastic case were the design/development team signatures. (Actually, I took it apart just to find the signatures.) That would have been a great morale thing for the team. And kinda cool. Here’s an example pic.

I had forgotten about that. I remember thinking that was a pretty cool idea the first time I stumbled upon it.