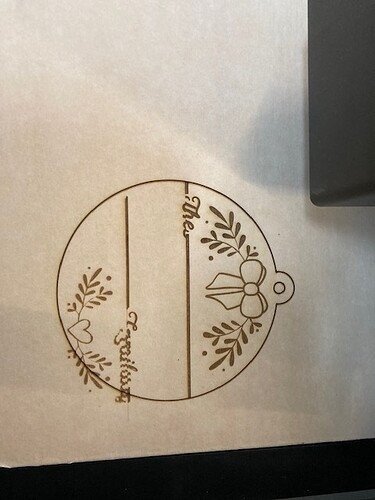

I just received my replacement "refurbished Glowforge Pro. There is a bubbling sound in the reservoir and very low fluid. The laser tube has small bubbles (after initial start up). Picture one shows a already cut ornament in the upper left, and where i attempted to burn the second in the same place. The machine burned it on the opposite side of the board. The second picture shows how the print came out. Any suggestions?

Thanks

J.R.

There are no pics.

Bubbles in the tube at initial startup is normal. It self purges the air out. Was the machine wet or dry inside when you received it? If it was dry with no sign of leakage then there is probably the correct amount of fluid in the reservoir.

Thanks. I am attempting to upload the pics. On initial startup the tube went from large bubbles to basically none as normal. Now there is a bubbling sound in the reservoir. I checked the fluid level and its down to maybe1/8 in the container. Im going to attempt to upload the pictures again.

The machine appeared to be dry. The box was busted all open though when I received it.

I have no idea what the normal level should be but 1/8 inch does seem quite low.

That was my thought, and probably cause for the bubbling sound.

Thanks

If you search “unicorn tears” you will find someone who may be able to help you round some fluid up (unless it’s still under warrantee?). As for the artwork switching sides that is odd behavior. I don’t have any idea what may have caused that.

Good luck.

Thanks beerfaced. Yes, it is till under warrantee. This is my fourth pro. I just recieced this replacement a couple days ago,

The coolant is a dilute antifreeze solution - water and glycol. The antifreeze is to prevent freezing during shipping and storage in unheated spaces like a garage. The big Chinese lasers just use an external pump and a bucket of water. There is nothing magical about the coolant, it’s a standard use in heat exchange, just like the radiator in your car.

If your machine lives in an unheated area it should have an antifreeze solution in it.

I personally wouldn’t risk shipping the machine back for that, a lot of the damage we have seen is from the handling during shipping.

After about 4 years I started getting tiny bubbles in the tube. The coolant level was just above the tank outlet, and I added an antifreeze solution to bring the tank level up to about 3/4 full.

Regarding the placement of your design, I don’t doubt what you’re saying, but if it happened to me, my first thought would be user error… somehow. ![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.