Your title issue, as well as these issues have been addressed. (Duplicate cut lines in the files causing charring and manual settings.) Your prints of the Gift of Good Measure in your post #28 show no differences between the machines.

The Glowforge is not adding extra cut lines, those are created by the newer versions of Illustrator when you save an SVG that has stroke lines that are not centered. Make sure all of your stroke lines are centered, (it’s not the default in AI). Your older files will likely still have the duplicate line problem. You’ll need to check each of your older files by opening them in Illustrator, clicking on View> Outline and then zoom in to see if there are two lines really close together. Delete one if there are two, then resave the file.

In order to address this issue, support will need to know how you are using the machine to see if you are doing it correctly.

- Are you using Set Focus?

- Did you run the Calibration routine for both machines?

The way that Set Focus works is: You click on Set Focus then click on the center of your design on the screen. The view will “temporarily” be corrected at that spot. Then you shift the design over until it falls on the material where you want it.

When the job is done, the screen view is going to shift back to the original view, including shifting the design on the screen. But the design will land where you wanted it to on the material, which is the point of the process. It might look like it jumped a long way, but if you click on Set Focus there again, you will see that it actually performed the job where you wanted it to.

Set Focus temporarily corrects the fisheye effect at the spot where it is clicked, then resets back to neutral when the job is over. (It’s a bit confusing at first, but you get used to it.) The point is you use Set Focus first, THEN shift the design for placement. A lot of people use it wrong. You can use it as many times as you need to before running the job if you have items scattered around the bed. Once you have clicked and placed in a location, do not shift that design again.

You are going to need to show some pictures of this effect, because it could be caused by a number of things. (Some of which you can fix.)

The jagged edges and uneven engraving might be caused by a slightly loose belt underneath the laser arm, or broken wheels on the Carriage Plate. Or it might be debris or junk on the tracks causing a physical hangup. Or you might be using different LPI values on each machine in the settings. But without seeing the results to analyze, it’s hard to tell you what to check next.

Still, because I am not on the forum much these days, and won’t be following up with this…

Since you have two machines, check the belt tension on one machine versus the other and see if there’s a difference.

1. To adjust the belt tension…follow the instructions below:

(You will need a 3mm hex key.)

You can lay a small flat mirror on the bed and see underneath the laser arm easily. (Always turn a machine off when working on it.) ![]()

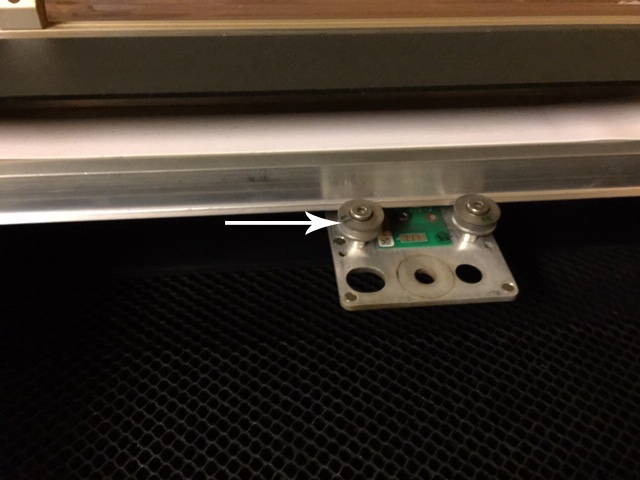

2. To check the wheels on the Carriage Plate you can see them by removing the head. (Make sure the machine is off.) Inspect them closely and move the plate by hand slowly left to right to see if they are hanging up on anything like debris. Usually it’s a good idea to clean the tracks while you can, just wipe them down with a slightly damp cloth.

(Your wheels will be a different color. This is a first run production model.)

3. If you are still noticing a difference between the two machines after you have checked those things, you will need to run the exact same file, with the same settings, on the same sheet of material in each machine. (Gift of Good Measure is usually used, on Proofgrade, because it is standardized.) Then post pictures of the results so the cut lines and engraving can be analyzed. Front and back. That will enable support to see what needs to happen next.

If the problem is always happening on acrylic, you can use Proofgrade acrylic for the test. If it’s only charring on one machine, you might need to clean the Air Assist fan, or make sure that it is functioning properly. (Instructions for that are here: Clean the Air Assist Fan.)

I know this is a lot of tests to run through, but you actually have multiple issues going on simultaneously…some of them were file related, some might be procedure related, and some might be machine related. You will need to check each of these items to narrow down what needs fixing and what needs to be changed procedurally.

Two months is too long to fiddle around with this. Run through each of the tests I listed, answer each question asked (and tell support the results), and hopefully you can make some progress on it.

Good luck.