Hello, thank you for letting us know about the trouble you’ve run into with your new Glowforge. To assist with troubleshooting, would you please check your X and Y axis belts for me to ensure they’re correctly tensioned?

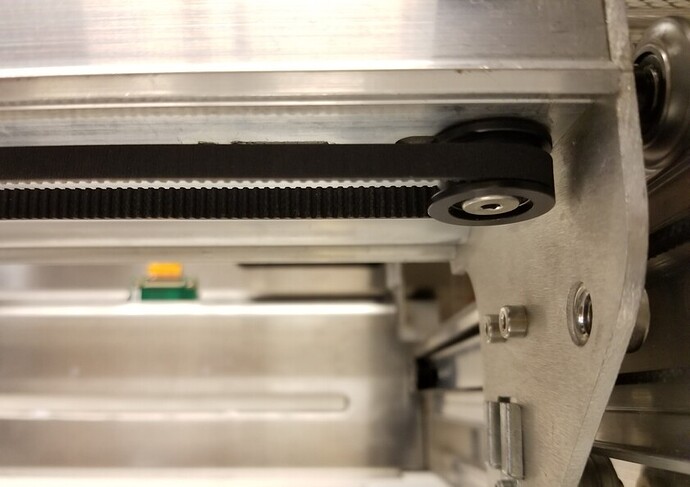

For the X axis belt (Located under the Laser Arm)

- Turn off your Glowforge.

- Carefully remove the crumb tray.

- Without removing the carriage plate and belt, locate the black pulley fastened by a metal screw on the right end of the laser arm.

- Insert the short side of the 3mm hex L-key into the metal screw with the long handle pointing toward the front of the unit.

- Turn the key clockwise to loosen the screw until the pulley can slide with some friction. Don’t remove the key from the screw.

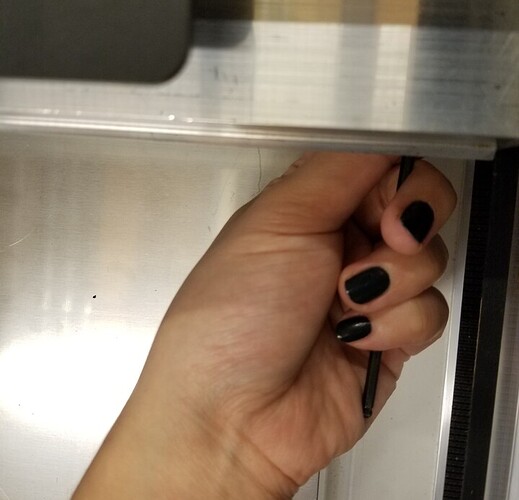

- Holding the key with your right hand, use your left index finger to push the pulley to the right until the belt is taugh. Don’t stretch the belt or touch the belt with your fingers as this can affect the tension on the belt.

- Applying firm pressure with your left index finger, turn the key counterclockwise to tighten the screw. Make sure the pulley doesn’t move during this time.

- Continue tightening the screw until you can’t turn the key anymore.

- Gently slide the carriage plate from side to side to ensure it moves smoothly and the belt does not catch or sag.

- If you’re not satisfied with the tension on the belt (it should be taut, but the belt shouldn’t be stretched), go back to step 4 and try again.

- If you are satisfied with the tension on the belt, try a test print. Print the Gift of Good Measure on the Proofgrade Draftboard we included in your material shipment for troubleshooting, and let me know how it goes!

If you have any questions or run into trouble along the way, don’t hesitate to reach out! I’m happy to help.

For the Y axis belts:

The Y Axis belts are located on the left and right side of the interior of your Glowforge.

Turn off your unit and move the laser arm to the front of the bed. There should be a black pulley connected to each belt on the far end of the rail. Try to wiggle the pulley and let me know if it’s secure.

After you’ve tried the above, please let us know how a test print goes.